2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Efficient and durable operation of electrical machines and installations directly depends on the state of insulation, for which electrical materials are used. They are characterized by a set of certain properties when placed in an electromagnetic field, and are installed in devices taking into account these indicators.

Classification of electrical materials allows us to divide into separate groups of electrical insulating, semiconductor, conductor and magnetic materials, which are complemented by basic products: capacitors, wires, insulators and finished semiconductor elements.

Materials work both in separate magnetic or electric fields with certain properties, and are exposed to several radiations at the same time. Magnetic materials are conditionally divided into magnets and weakly magnetic substances. In electrical engineering, highly magnetic materials are most widely used.

Science ofmaterials

A material is a substance characterized by a chemical composition, properties and structure of molecules and atoms different from other objects. Matter is in one of four states: gaseous, solid, plasma or liquid. Electrical and structural materials perform a variety of functions in the installation.

Conductive materials carry out the transmission of the electron flow, dielectric components provide insulation. The use of resistive elements converts electrical energy into thermal energy, structural materials retain the shape of the product, for example, the case. Electrical and structural materials necessarily perform not one, but several related functions, for example, the dielectric in the operation of an electrical installation experiences loads, which brings it closer to structural materials.

Electrotechnical materials science is a science that deals with the determination of properties, the study of the behavior of a substance when exposed to electricity, heat, frost, magnetic field, etc. Science studies the specific characteristics necessary to create electrical machines, devices and installations.

Conductors

These include electrical materials, the main indicator of which is the pronounced conductivity of electric current. This happens because electrons are constantly present in the mass of matter, weakly bound to the nucleus and being free charge carriers. They move from the orbit of one molecule to another and create a current. The main conductor materials are copper, aluminum.

Conductors include elements that have electrical resistivity ρ < 10-5, while an excellent conductor is a material with an indicator of 10-8Ohmm. All metals conduct current well, out of 105 elements of the table only 25 are not metals, and from this heterogeneous group 12 materials conduct electric current and are considered semiconductors.

The physics of electrical materials allows their use as conductors in the gaseous and liquid state. As a liquid metal with a normal temperature, only mercury is used, for which this is a natural state. The remaining metals are used as liquid conductors only when heated. For conductors, conductive liquids, such as electrolyte, are also used. Important properties of conductors, allowing them to be distinguished by the degree of electrical conductivity, are the characteristics of thermal conductivity and the ability to thermal generation.

Dielectric materials

Unlike conductors, the mass of dielectrics contains a small number of free elongated electrons. The main property of a substance is its ability to obtain polarity under the influence of an electric field. This phenomenon is explained by the fact that under the action of electricity, the bound charges move towards the acting forces. The displacement distance is greater, the higher the electric field strength.

Insulating electrical materials are the closer to the ideal, the lessan indicator of specific conductivity, and the less pronounced the degree of polarization, which makes it possible to judge the dissipation and release of thermal energy. The conductivity of a dielectric is based on the action of a small number of free dipoles shifting in the direction of the field. After polarization, the dielectric forms a substance with different polarity, that is, two different signs of charges are formed on the surface.

The use of dielectrics is most extensive in electrical engineering, as the active and passive characteristics of the element are used.

Active materials with manageable properties include:

- pyroelectrics;

- electrophosphors;

- piezoelectrics;

- ferroelectrics;

- electrets;

- materials for laser emitters.

The main electrical materials - dielectrics with passive properties, are used as insulating materials and capacitors of the usual type. They are able to separate two sections of the electrical circuit from one another and prevent the flow of electric charges. With their help, current-carrying parts are insulated so that electrical energy does not go into the ground or to the case.

Dielectric separation

Dielectrics are divided into organic and inorganic materials, depending on the chemical composition. Inorganic dielectrics do not contain carbon in their composition, while organic forms have carbon as the main element. inorganic substances such as ceramics,mica, have a high degree of heating.

Electrotechnical materials according to the method of obtaining are divided into natural and artificial dielectrics. The widespread use of synthetic materials is based on the fact that manufacturing allows you to give the material the desired properties.

According to the structure of molecules and the molecular lattice, dielectrics are divided into polar and non-polar. The latter are also called neutral. The difference lies in the fact that before the electric current begins to act on them, atoms and molecules either have or do not have an electric charge. The neutral group includes fluoroplastic, polyethylene, mica, quartz, etc. Polar dielectrics consist of molecules with a positive or negative charge, an example is polyvinyl chloride, bakelite.

Properties of dielectrics

As dielectrics are divided into gaseous, liquid and solid. The most commonly used solid electrical materials. Their properties and applications are evaluated using indicators and characteristics:

- volume resistivity;

- dielectric constant;

- surface resistivity;

- thermal permeability coefficient;

- dielectric losses expressed as tangent of angle;

- strength of material under the action of electricity.

Volume resistivity depends on the ability of a material to resist the flow of a constant current through it. The reciprocal of resistivity is called volume specificconductivity.

Surface resistivity is the ability of a material to resist direct current flowing across its surface. Surface conductivity is the reciprocal of the previous value.

The thermal permeability coefficient reflects the degree of change in resistivity after increasing the temperature of a substance. Usually, as the temperature increases, the resistance decreases, therefore, the value of the coefficient becomes negative.

Dielectric constant determines the use of electrical materials in accordance with the ability of the material to create electrical capacitance. The relative permeability of a dielectric is included in the concept of absolute permeability. The change in capacitance of the insulation is shown by the previous indicator of the coefficient of thermal permeability, which simultaneously shows an increase or decrease in capacitance with a change in temperature.

The dielectric loss tangent reflects the amount of power loss in a circuit relative to the dielectric material subjected to an electrical alternating current.

Electrical materials are characterized by an indicator of electrical strength, which determines the possibility of destruction of a substance under the influence of stress. When identifying mechanical strength, there are a number of tests to establish an indicator of ultimate strength in compression, tension, bending, torsion, impact and splitting.

Physical and chemical properties of dielectrics

Dielectrics contain a certain numberreleased acids. The amount of caustic potassium in milligrams required to get rid of impurities in 1 g of a substance is called the acid number. Acids destroy organic materials, have a negative effect on insulating properties.

The characteristic of electrical materials is supplemented by a coefficient of viscosity or friction, showing the degree of fluidity of a substance. Viscosity is divided into conditional and kinematic.

The degree of water absorption is determined depending on the mass of water absorbed by the element of the test size after a day of being in water at a given temperature. This characteristic indicates the porosity of the material, increasing the value degrades the insulating properties.

Magnetic materials

Indicators for evaluating magnetic properties are called magnetic characteristics:

- magnetic absolute permeability;

- magnetic relative permeability;

- thermal magnetic permeability;

- energy of maximum magnetic field.

Magnetic materials are divided into hard and soft. Soft elements are characterized by small losses when the magnitude of the magnetization of the body lags behind the acting magnetic field. They are more permeable to magnetic waves, have a small coercive force and increased inductive saturation. They are used in the construction of transformers, electromagnetic machines and mechanisms, magnetic screens and other devices where magnetization with low energy is required.omissions. These include pure electrolyte iron, iron - armco, permalloy, electrical steel sheets, nickel-iron alloys.

Solid materials are characterized by significant losses when the degree of magnetization lags behind an external magnetic field. Having received magnetic impulses once, such electrical materials and products are magnetized and retain the accumulated energy for a long time. They have a large coercive force and a large residual induction capacity. Elements with these characteristics are used for the manufacture of stationary magnets. The elements are represented by iron-based alloys, aluminum, nickel, cob alt, silicon components.

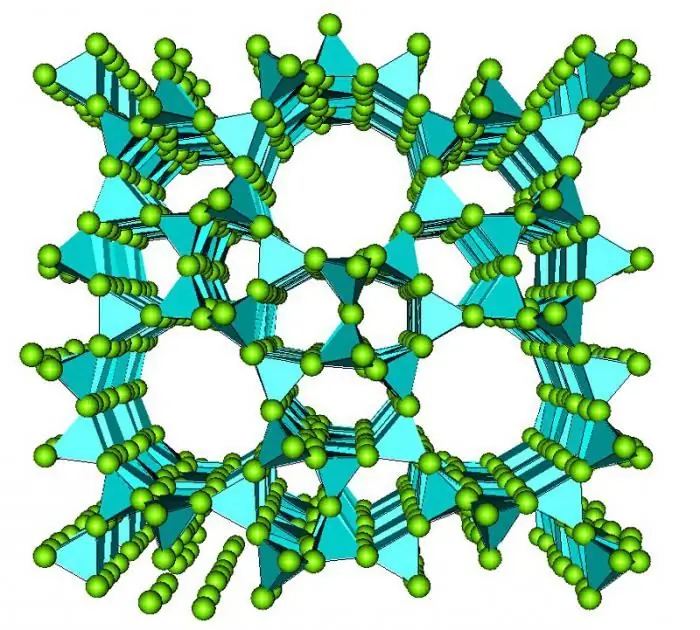

Magnetodielectrics

These are mixed materials, containing 75-80% magnetic powder, the rest of the mass is filled with an organic high-polymer dielectric. Ferrites and magnetodielectrics have high values of volume resistivity, small eddy current losses, which allows them to be used in high-frequency technology. Ferrites have stable performance in various frequency fields.

Field of use of ferromagnets

They are used most effectively to create the cores of transformer coils. The use of the material allows you to greatly increase the magnetic field of the transformer, while not changing the current readings. Such inserts made of ferrites allow you to save electricity consumption during the operation of the device. Electrical materials and equipment after turning off the external magnetic effect retainmagnetic indicators, and maintains the field in the adjacent space.

Elementary currents do not pass after the magnet is turned off, thus creating a standard permanent magnet that works effectively in headphones, telephones, measuring instruments, compasses, sound recorders. Permanent magnets that do not conduct electricity are very popular in application. They are obtained by combining iron oxides with various other oxides. Magnetic iron ore is a ferrite.

Semiconductor materials

These are elements that have a conductivity value that is in the range of this indicator for conductors and dielectrics. The conductivity of these materials directly depends on the manifestation of impurities in the mass, external directions of impact and internal defects.

Characteristics of electrical materials of the semiconductor group indicates a significant difference between the elements from each other in the structural lattice, composition, properties. Depending on the specified parameters, materials are divided into 4 types:

- Elements containing atoms of the same type: silicon, phosphorus, boron, selenium, indium, germanium, gallium, etc.

- Materials containing metal oxides - copper, cadmium oxide, zinc oxide, etc.

- Materials combined into the antimonide group.

- Organic materials - naphthalene, anthracene, etc.

Depending on the crystal lattice, semiconductors are divided into polycrystalline materials and monocrystallineelements. The characteristic of electrical materials allows them to be divided into non-magnetic and weakly magnetic. Among the magnetic components, semiconductors, conductors and non-conductive elements are distinguished. A clear distribution is difficult to make, since many materials behave differently under changing conditions. For example, the operation of some semiconductors at low temperatures can be compared to the operation of insulators. The same dielectrics work like semiconductors when heated.

Composite materials

Materials that are not divided by function, but by composition, are called composite materials, these are also electrical materials. Their properties and application are due to the combination of materials used in the manufacture. Examples are sheet glass fiber components, fiberglass, mixtures of electrically conductive and refractory metals. The use of equivalent mixtures allows you to identify the strengths of the material and apply them for their intended purpose. Sometimes a combination of composites results in a completely new element with different properties.

Film materials

Films and tapes as electrical materials have won a large area of application in electrical engineering. Their properties differ from other dielectrics in flexibility, sufficient mechanical strength and excellent insulating characteristics. The thickness of products varies depending on the material:

- films are made with a thickness of 6-255 microns, tapes are produced in 0.2-3.1 mm;

- polystyrene products in the form of tapes and films are produced with a thickness of 20-110 microns;

- polyethylene tapes are made with a thickness of 35-200 microns, a width of 250 to 1500 mm;

- fluoroplastic films are made with a thickness of 5 to 40 microns, a width of 10-210 mm.

Classification of electrical materials from the film allows us to distinguish two types: oriented and non-oriented films. The first material is used most often.

Varnishes and enamels for electrical insulation

Solutions of substances that form a film during solidification are modern electrical materials. This group includes bitumen, drying oils, resins, cellulose ethers or compounds and combinations of these components. The transformation of a viscous component into an insulator occurs after evaporation from the mass of the applied solvent, and the formation of a dense film. According to the method of application, films are divided into adhesive, impregnating and coating.

Impregnating varnishes are used for windings of electrical installations in order to increase the coefficient of thermal conductivity and resistance to moisture. Coating varnishes create an upper protective coating against moisture, frost, oil for the surface of the windings, plastics, insulation. Adhesive components are capable of bonding mica plates to other materials.

Compounds for electrical insulation

These materials are presented as a liquid solution at the time of use, followed by solidification and hardening. Substances are characterized by the fact that they do not contain solvents. Compounds also belong to the group "electrotechnical materials". Their types are filling and impregnating. The first type is used to fill cavities in cable sleeves, and the second group is used to impregnate motor windings.

Compounds are produced thermoplastic, they soften after increasing temperatures, and thermoset, firmly retaining the shape of curing.

Fibrous non-impregnated electrical insulating materials

For the production of such materials, organic fibers and artificially created components are used. Natural plant fibers of natural silk, linen, wood are converted into materials of organic origin (fiber, fabric, cardboard). The humidity of such insulators ranges from 6-10%.

Organic synthetic materials (kapron) contain moisture only from 3 to 5%, the same saturation with moisture and inorganic fibers (glass fiber). Inorganic materials are characterized by their inability to ignite when heated significantly. If the materials are impregnated with enamels or varnishes, then the combustibility increases. The supply of electrical materials is made to an enterprise for the manufacture of electrical machines and devices.

Letheroid

Thin fiber is produced in sheets and rolled into a roll for transportation. It is used as a material for the manufacture of insulation gaskets, shaped dielectrics, washers. Asbestos-impregnated paper and asbestos cardboard are made from chrysolite asbestos, splitting it into fibers. Asbestos is resistant to alkaline environments, but is destroyed in acidic environments.

In conclusion, it should be noted that with the use of modern materials for the insulation of electrical appliances, their service life has significantly increased. Materials with selected characteristics are used for the bodies of the installations, which makes it possible to produce new functional equipment with improved performance.

Recommended:

Types of repairs of electrical equipment and their characteristics

The performance of power equipment is largely determined by its proper maintenance. Repair work is an integral part of the operation that must be carried out in electrical installations. What types of repairs of electrical equipment exist, their features and deadlines. Read more about it later in the article

Zeolite - what is it? Zeolite natural and synthetic. Zeolite: properties, applications, benefits and harms

Its name translates as "boiling stone". It is impossible to count the uses of this seemingly simple mineral. It can even be eaten and used as a sieve for molecules. Such a versatile and useful zeolite

Work permit for work in electrical installations. Rules for work in electrical installations. Work permit

From August 2014, Law No. 328n comes into force. In accordance with it, a new edition of the "Rules on labor protection during the operation of electrical installations" is being introduced

Protective materials: types, properties and applications

Today, people actively use a wide variety of devices, devices, etc. All this is made of parts that sooner or later become unusable, due to which the equipment stops working normally. To delay this moment as much as possible, protective materials are used

What is an electrical substation? Electrical substations and switchgear

Trams and trolleybuses require voltage not alternating, but constant. This means that a separate very powerful substation is needed. Electrical energy is converted on it, that is, it is rectified