2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:28

The performance of power equipment is largely determined by its proper maintenance. Repair work is an integral part of the operation that must be carried out in electrical installations. What types of repairs of electrical equipment exist and what are their features and deadlines, read further in the article.

What is electrical repair?

The presented concept should be understood as the restoration of the original properties of the product using consumables, specialized tools and equipment. During the repair process, defective parts, worn items, and so on are changed.

It should be noted that in conditions of high wear and tear, as well as a huge number of power equipment, modern divisions of electrical networks do not have time to meet the planned targets for the repair campaign. Another problem relates to repayment issues.consumers, which clearly complicates the procedure.

As for the sequence of actions, almost all types of electrical equipment repairs are carried out in the following sequence:

- Diagnosis. It involves identifying defects using a physical inspection, examining the equipment for burning contacts with pyrometers or testing with increased voltage, megger.

- Carrying out repairs that are aimed at eliminating the identified shortcomings. When carrying out the procedure, individual parts (transformer stud), components (HV drive) or the entire unit (replacement of a linear disconnector.) may be suitable for replacement.

- Carrying out repeated diagnostics and commissioning of equipment. The latter is associated with the human factor, improper mounting or other features that will lead to a short circuit or other troubles.

Proper implementation and following the steps eliminates errors, prolongs the life of electrical equipment. However, this approach requires a lot of time, which is unacceptable in conditions of a large number of power and other equipment.

The Importance of Periodic Maintenance

Repair or overhaul provides the following benefits:

- Reducing the number of outages, as the updated period of operation and the elimination of defects have a beneficial effect on the presented figure.

- Different types and terms of repair of electrical equipmentprovide an overview of problem areas in the network that require maintenance and tidying up.

- Timely repair is a guarantee of safe operation of electrical installations. This reduces the risk of unintended consequences after switching.

- The absence of emergencies implies less damage to the electric power industry. Therefore, performing routine repairs and scheduled walkdowns is a necessary procedure.

At the moment there are several variations on the division of repair work. Let's take a look at each category below.

Types of electrical repairs

There are a number of gradations for the implementation of repair work. First: division according to the degree and depth of the actions carried out. Here, the current and capital are distinguished, the terms of which are determined in the PTE, as well as the documentation of the supplier of power equipment. The second is associated with the cause of occurrence. Here it is necessary to consider planned actions, unplanned and emergency.

The choice of one or another option is largely determined by the conditions of the need for repair work, as well as the degree and depth of the execution of the tasks. Note that all variations are prescribed in the technical documentation of the industry and power industry enterprises.

Current

This type of repair of electrical equipment involves the timely restoration of electrical network elements through maintenance orcomplete replacement of individual parts. With the complexity, as well as the high volume of operations, there is a division of repair work into several stages. Determining the need for current repairs is carried out by the passports of objects, transformer substations.

In some cases, the implementation of the procedure is associated with emergency situations. It is easier for the foremen of the teams to prepare a workplace according to the orderly system for current repairs than to fulfill emergency requests in haste. The procedure is less time-consuming and involves lower costs for maintaining the equipment.

Capital

Another main type of repair of electrical equipment should include the above. The process assumes wear by 80%, which requires the systematic replacement of not only individual parts and parts, but also full-fledged assemblies. In some cases, the concept is associated with modernization, which involves improving the system without losing its original properties.

Replacement and implementation of overhaul is regulated by the PTE and local documentation, passports of energy facilities. A prerequisite for carrying out full-fledged repair work is the issuance of technical specifications for the implementation of relevant actions. There are other subtleties here that the administrative and technical staff should study.

Planned

Implementation of the repair campaign is planned on the eve of the beginning of the calendar year. All actions that are coming for the future are signed in the plans, which predetermines this group. This does not include emergency types of work on the repair of electrical equipment, mainly this is the overhaul of substations. The formation of the list depends on the technical department, which identifies electrical installations in need of service.

Documentation is approved by the chief engineer and brought to the attention of the foremen for cable / overhead lines, RP / TP / PTS, administrative and technical staff. In most cases, the accrual of bonuses for employees depends on the performance of the presented indicator. Information is given to higher structures about the progress of the repair campaign, and the breakdown rate of networks depends on it.

Unscheduled

It is simply impossible to plan and take into account everything, therefore an unscheduled type of repair of electrical equipment at the enterprise is necessary. During scheduled inspections, tests, defects appear that need to be eliminated. In the absence of action to eliminate defective components or assemblies, there is a significant risk of more serious emergencies.

In most cases, this category involves the implementation of current repairs. However, in some situations, at the discretion of the chief engineer and higher-level personnel, decisions may be made to overhaul or replace equipment completely. It all depends on the ratio of safety / reliability / efficiency.

Emergency

Emergency types of repairs of electrical equipment and their characteristics are determinedemergency situation on the failure of electrical installations. Any breakdown at the substation (switching devices, power transformers, cable lines, overhead lines) requires the implementation of the appropriate type of repair work. The presented variation assumes the maximum speed of eliminating the problem and powering consumers. Such repair procedures are carried out by specialized high-voltage crews or HVU.

It should be noted that this is an extreme scenario. Scheduled maintenance should prevent such an outcome. Emergencies can often arise due to the human factor, for example, the work of third-party organizations in the security zone of overhead lines. Extraordinary situations often result in more damage to the enterprise than planned maintenance.

Conclusion

Repair work is needed to keep the networks running. The types and frequency of repair of electrical equipment are determined by various documents, as well as the conditions for detecting defects and malfunctions. At the moment, there are two main types that predetermine the timing, depth and other parameters of the implementation of the tasks.

For the timing of various types of repair work, we recommend that you read the "Operation Rules", "Intersectoral Rules for the Commissioning of New Equipment", as well as local documentation of enterprises. This will allow you to delve into the issue and gain additional knowledge regarding the implementation of the repair campaign. This literature will be sufficient for a complete understanding of the essence of the issue.

Recommended:

Thermal imaging control of electrical equipment: concept, principle of operation, types and classification of thermal imagers, features of application and verification

Thermal imaging control of electrical equipment is an effective way to identify defects in power equipment that are detected without shutting down the electrical installation. In places of poor contact, the temperature rises, which is the basis of the methodology

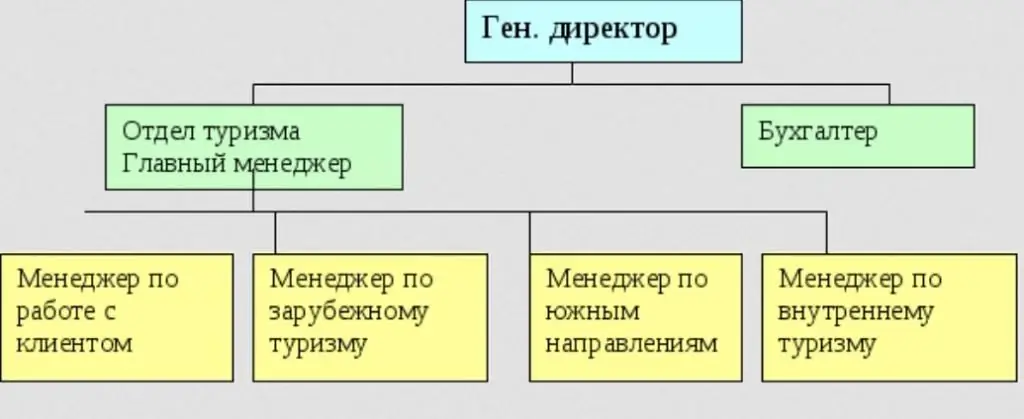

Types of tour operators and their characteristics. Functions and features of the activities of tour operators

The tour operator provides a wide range of travel services and simplifies the reservation of services in other cities and countries, taking on these tasks. In the field of tourism services, it occupies a special niche. In the article we will consider the types of activities of tour operators

Non-ferrous, precious and ferrous types of metals and their characteristics

Metals are a large group of simple elements with characteristic features such as high thermal and electrical conductivity, positive temperature coefficient and more. To properly classify and understand what's what, you need to deal with all the nuances. Let's try with you to consider such basic types of metals as ferrous, non-ferrous, precious, as well as alloys. This is quite an extensive and complex topic, but we will try to put everything on the shelves

What is an electrical substation? Electrical substations and switchgear

Trams and trolleybuses require voltage not alternating, but constant. This means that a separate very powerful substation is needed. Electrical energy is converted on it, that is, it is rectified

Gas drying: definition, characteristics, methods and types of work, application of installation and special equipment

Gas drying is one of the cleaning methods that helps to get rid of moisture inside the pipeline. Its appearance is quite dangerous, as it causes corrosion of the metal. In addition, since mining is also carried out in conditions of low temperatures, ice formation is possible