2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

Many industrial processes are accompanied by air pollution, which necessitates timely cleaning of the workspace to improve sanitary conditions. Ventilation systems, even in industrial design, are not able to provide sufficient performance for the removal of fine particles produced by processing equipment. Therefore, in solving such problems, special dust-collecting units of various types and modifications are used.

Basic equipment classification

Dust collectors are included in the general group of industrial devices designed for air purification along with gas filtration systems. Such units are commonly used in the food, woodworking and chemical industries, providing delay andremoval of both fine dust and husks. One of the main features of the separation of dust collecting units into types is the principle of interaction with the ventilation system. According to this parameter, two main types of this equipment are distinguished:

- Installations that are used to clean the air flows coming through the supply ventilation system. Such equipment can be integrated into air heating and air conditioning communications.

- Installations that are also used to clean the air, but on the way to the release of polluted flows from the exhaust ventilation system into the atmosphere.

In both groups, the devices can work according to a different principle and, accordingly, have a different structural device.

Gravity dust collectors

Dust collectors and dust chambers stand out in this category. In the first version, we are talking about screw collectors that perform the function of preliminary air purification. The dust collector is installed in front of the suction filter and cuts off solid particles, leaving them in a special bag or on the walls of the exhaust pipe. Periodically, the flow paths are cleaned or replaced. As for sediment chambers, this is also a kind of ventilation dust-collecting unit for preliminary, but already rough cleaning.

Such systems, in particular, are used to service grain processing plants that produce coarse dust. Gravitational separation principledust particles from the air involves the use of kinetic energy of foreign elements in order to collect them at the bottom of a special chamber. Conditions are created in the air duct for laminar or turbulent movement of flows with dust at a speed sufficient for the fall of suspended particles. In this case, there can be several chambers, which increases the cleaning efficiency. But even in this case, the effect of fine filtration that meets sanitary requirements cannot be achieved.

Inertial units

An extensive group of devices that are used to purify air from dust of various fractions - including broken and fibrous elements, particles of grain husks, etc. An inertial dust-collecting unit called a cyclone allows you to achieve the greatest filtering effect. Actually, this is one of the steps in the complex purification of dusty air, but it is also the most productive.

The design of such a unit is formed by a storage bin, a special air duct with a narrowed cross section (directly a cyclone), bag filters, an outlet pipe, a casing and, in some cases, an automatic shaking system. Due to the expanded section at the inlet to the duct, the speed of the air flow is reduced, after which it twists into a cyclone spiral and is directed perpendicular to the original direction. During this process, dust settles in a storage bin, which is also cleaned at regular intervals.

Wet units

For air purification from fine,sticky and flammable dust, special installations with wet collection are used. In essence, this is a modification of the cyclone with a water film, which traps contaminants with fibrous inclusions. The unit consists of a cylindrical air duct with a conical bottom, air outlet pipes and a conductive volute. The principle of operation of the dust collecting unit is to retain solid particles on the walls of the air duct, which are irrigated by nozzles located in the upper part of the cyclone under a pressure of about 2-2.5 kPa. When cleaning from target particles with a fraction from 5 to 10 microns, it is possible to achieve an efficiency factor of up to 95%. Water consumption in this case is 0.2-0.3 l/m3

Features of recirculation units

Specially for the removal of fine dust in low concentrations (up to 20 mg/m3) a recirculation unit is designed. Such units are used not only in the maintenance of industrial processing equipment, but also in spot welding, as well as in technological operations related to the soldering of parts.

The main design features of recirculating dust collecting units include two-stage cleaning, which is provided by filter materials that allow manual regeneration. Unlike many other systems that remove air, the separated streams in this case are not completely removed to the outside, but are stored in the room after cleaning. Despite the reduction in filtration quality, this solution has a significant advantage,which is to maintain the thermal regime. This allows you to reduce the cost of heating industrial premises in cold weather by reducing the volume of low-temperature outdoor air.

Conclusion

In the Russian market, dust-collecting plants are presented in a wide range, and the nomenclature is segmented not only by functional and structural characteristics, but also by the specifics of operating conditions. So, especially for medium-sized enterprises of the woodworking industry, the dust-collecting unit PU-1500 is designed to trap chips, sawdust, as well as small particles with a fraction of 5 microns. The ZIL series units are widely used in the metalworking industry. These are industrial vacuum cleaners that are interfaced with sharpening, metal-cutting and grinding machines. Specific models are recommended to be selected based on the area of the room, the characteristics of dust and impurities, as well as the technical conditions for installation and connection of equipment at the place of operation.

Recommended:

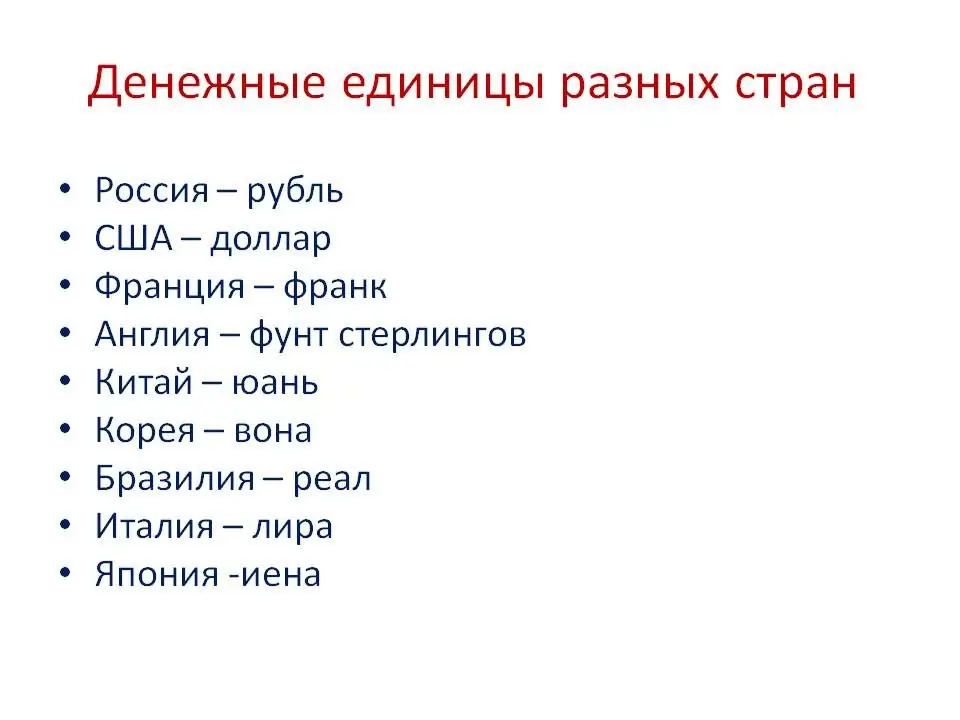

Monetary unit - what is it? Definition of the monetary unit and its types

The monetary unit serves as a measure for expressing the value of goods, services, labor. On the other hand, each monetary unit in different countries has its own measure of measurement. Historically, each state sets its own unit of money

The best dust collector: overview, specifications and operating rules

Ventilation dust collector (UPV) is a device designed for air filtration. The separation of impurities is carried out in special filters

How to choose industrial vacuum cleaners without a dust bag

The article is devoted to industrial vacuum cleaners without a dust bag. The main selection criteria and the best manufacturers of this equipment are considered

What is abrasive dust?

The article is devoted to abrasive dust. The features of the material, its characteristics, as well as methods for removing

Arrears are Features of collecting arrears

Tax arrears are, in a word, debt. It is formed in case of non-payment of a mandatory payment to the budget within the time period established by law