2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:36

Perhaps the most widespread protective materials are in the field where metal is actively used. For example, the operation of a variety of machines is ensured by the fact that their elements are made of materials that are highly resistant to wear and corrosion.

Galvanic protective equipment

As for the wear of machine parts, for example, most often this happens due to the constant friction of the elements against each other. It can also be influenced by the surrounding work area. In order to significantly increase the wear resistance of such parts, protective materials are used. For example, they are very widely used to protect cylinders in an internal combustion engine. The most effective method to preserve a metal surface is to apply electroplating.

Using these coatings as protection helps in the following:

- reduces wear on parts;

- decorative appearance is improved if a protective and decorative coating is used;

- already worn out elements are restored;

- strength increasesclutch.

Chrome plating

Chrome can be used as a protective material. Chrome plating of parts is the application of a decorative and protective layer. This procedure can significantly increase wear resistance, as well as restore already worn parts, if the porous chromium plating procedure is used. However, it should be noted that this procedure is not always relevant. The use of chromium as a protective coating for the restoration of parts becomes irrational if the wear exceeds 0.7-1 mm.

In addition, coating with this alloy significantly increases the resistance of the metal to corrosion. For this reason, the best anti-corrosion agents for a car are those made on the basis of chromium. There are two types of parts that require chrome plating:

- Elements that need to increase wear resistance if they experience high friction during operation.

- Also, chromium plating can restore the size of a part that was underestimated during machining.

Protective thermal insulation materials

Today, the use of protective materials of a heat-insulating type is quite widespread. Their choice is considered quite difficult, since substances have a huge number of characteristics. For this reason, each substance can be used in a specific environment, based on its parameters.

As for the choice of such a protective agent,then you need to pay attention to the following points:

- scope and purpose of the material;

- flame resistance value of the product;

- value of resistance to moisture and harmful insects;

- possible impact on microclimatic conditions or human he alth;

- price.

Moisture proof properties

One of the main properties of protective materials is moisture resistance, especially when it comes to insulating coating. In this case, the less moisture the material absorbs, the better. This is due to the fact that water completely destroys the quality of the insulating material, as it is an excellent conductor. In addition, in the joint areas there is a high risk of mold or decay with low moisture resistance. Therefore, any docking area must be completely dehydrated.

It should also be understood that moisture is not only a liquid. Water vapor, for example, is also quite dangerous. Therefore, it is very important to take into account that this type of protective material also has a high vapor-water impermeability. Due to the fact that the humidity in the street and indoors are usually different, there is a tendency for it to equalize. Moisture usually enters through ventilation. However, steam penetration is possible even through the outer walls of the building. In this case, the steam will cool and condense, which will lead to moisture on any structure.

Chemical properties and insect resistance

It is very important that protectivethe materials did not cause corrosion on the surrounding products when in contact. However, the protective coating must be resistant to the substance with which it will come into contact. This is most important when different chemistries are used.

Today, modern protective materials are highly resistant to insects, which in some cases can also cause significant harm. Most of all, such a protective coating is necessary for such materials and products from them as peat, straw, reed. Nesting pests in this case is a fairly common occurrence. A small protective coating for them can be made even with your own hands. Hydrated lime is perfect.

Human he alth

Many are wondering how and whether a protective substance affects human he alth. It is worth noting here that it is rather problematic to answer this question precisely, since the manufacturers of these substances usually do not disclose the full list of substances used, as well as the technology of creation, which, in principle, is understandable.

In this case, you should pay attention to the main substances that are used to create this kind of materials. Usually these are plant and mineral components. There are no harmful effects of these substances on human he alth. More doubtful is the use of a variety of synthetic components. For this reason, it is necessary to make sure that such funds undergo special treatment, which should reduceharmful effects on human he alth.

For example, when creating a protective agent, the mineral components are processed to such small particles that during their normal use, when inhaled, they will enter the body, causing a deterioration in well-being. Therefore, you need to make sure that the composition contains a binder that will prevent the mineral components from getting into the air during use. In this case, the protective agent can be considered safe.

Environment and processing

In addition to the impact on the human body, you need to remember that these substances should not have a strong impact on the environment. For example, the use of protective equipment in construction is limited to a certain period, since any composition, even the highest quality, will sooner or later "grow old". When this happens, such elements are removed. They are taken to certain landfills, where they are burned. All this leads to the fact that it is preferable to use mineral or vegetable components for a protective agent, since they will not emit harmful substances when burned.

The last thing you can add about conventional protective equipment is that they are all attached or applied in different ways. Most often, the coating is fastened with nails, screws or screws. For example, if the protective coating is presented in the form of a plate, then it is pierced with nails, after which it is lined with an adhesive.

Compositesubstances

Composite materials are substances that consist of several components. Usually the structure looks like this: there is a base or a plastic-looking matrix, which is additionally reinforced with a variety of fillers. Depending on this filler, it is possible to create a coating that is more durable, tough, resistant to corrosion or moisture. In other words, the use of a composite material as a protective agent is more beneficial, as protection against various influences can be achieved.

As for the structure of such substances, a few of the most common are usually used. These include fibrous, layered, nanocomposite and other structures. Fibrous type composites are usually reinforced with fibers of the desired substance. The layered structure has the form of a "pie", where the matrix and the filler go one after another in layers.

It should also be said that radiation-protective materials also most often belong to the composite type, since here maximum protection from many negative influences is required at once.

Recommended:

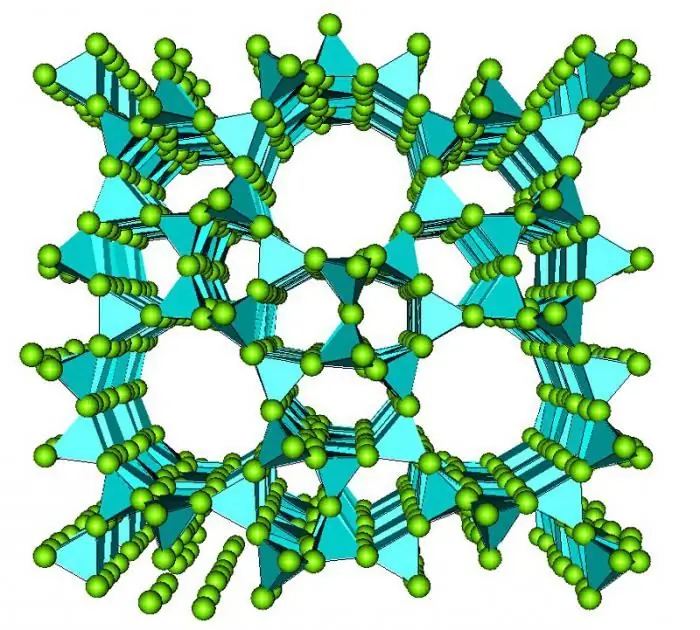

Zeolite - what is it? Zeolite natural and synthetic. Zeolite: properties, applications, benefits and harms

Its name translates as "boiling stone". It is impossible to count the uses of this seemingly simple mineral. It can even be eaten and used as a sieve for molecules. Such a versatile and useful zeolite

Steel: composition, properties, types and applications. Composition of stainless steel

Today, steel is used in the vast majority of industries. However, not everyone knows that the composition of steel, its properties, types and applications are very different from the production process of this product

Electrical materials, their properties and applications

Efficient and durable operation of electrical machines and installations directly depends on the state of insulation, for which electrical materials are used. They are characterized by a set of certain properties when placed in an electromagnetic field, and are installed in devices taking into account these indicators

Aluminum grades: types, properties and applications

Today, aluminum is used in almost all industries, from the production of food utensils to the creation of spacecraft fuselages. For certain production processes, only certain grades of aluminum are suitable, which have certain physical and chemical properties

Two-component polyurethane sealant: definition, creation, types and types, characteristics, properties and nuances of application

With long-term and high-quality sealing of seams and cracks, polyurethane two-component sealants have found their wide distribution. They have high deformation and elastic properties, therefore, they can be used as butt sealants in the field of repair and housing construction