2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:29

Heat energy occupies a special place in human activity, since it is used in all sectors of the economy, accompanies most industrial processes and people's livelihoods. In most cases, waste heat is lost irrevocably and without any economic benefit. This lost resource is no longer worth anything, so reusing it will help both reduce the energy crisis and protect the environment. Therefore, new ways of converting thermal energy into electrical energy and the conversion of waste heat into electricity are more relevant today than ever.

Types of electricity generation

Transforming natural energy sources into electricity, heat or kinetic energy requires maximum efficiency, especially in gas and coal-fired power plants, to reduce CO2 emissions2. There are various ways to convertthermal energy into electrical energy, depending on the types of primary energy.

Among the energy resources, coal and natural gas are used to generate electricity by combustion (thermal energy), and uranium by nuclear fission (nuclear energy) to use steam power to turn a steam turbine. The top ten electricity producing countries for 2017 are shown in the photo.

Table of the efficiency of existing systems for the conversion of thermal energy into electrical energy.

| Generation of electricity from thermal energy | Efficiency, % | |

| 1 | Thermal power plants, CHP plants | 32 |

| 2 | Nuclear plants, nuclear power plants | 80 |

| 3 | Condensing Power Plant, IES | 40 |

| 4 | Gas turbine power plant, GTPP | 60 |

| 5 | Thermionic transducers, TECs | 40 |

| 6 | Thermoelectric generators | 7 |

| 7 | MHD power generators together with CHP | 60 |

Choosing a method for converting thermal energy intoelectrical and its economic feasibility depend on the need for energy, the availability of natural fuel and the sufficiency of the construction site. The type of generation varies around the world, resulting in a wide range of electricity prices.

Problems of traditional electric power industry

Technologies for converting thermal energy into electrical energy, such as thermal power plants, nuclear power plants, IES, gas turbine power plants, thermal power plants, thermoelectric generators, MHD generators have different advantages and disadvantages. The Electric Power Research Institute (EPRI) illustrates the pros and cons of natural energy generation technologies, looking at critical factors such as construction and costs of electricity, land, water requirements, CO emissions2, waste, affordability and flexibility.

EPRI results highlight that there is no one-size-fits-all approach when considering power generation technologies, yet natural gas still benefits more because it is affordable for construction, has a low cost of electricity, generates less emissions than coal. However, not all countries have access to abundant and cheap natural gas. In some cases, access to natural gas is under threat due to geopolitical tensions, as was the case in Eastern Europe and some Western European countries.

Renewable energy technologies such as windturbines, solar photovoltaic modules produce emission electricity. However, they tend to require a lot of land, and the results of their effectiveness are unstable and depend on the weather. Coal, the main source of heat, is the most problematic. It leads in CO emissions2, requires a lot of clean water to cool the coolant and occupies a large area for the construction of the station.

New technologies aim to reduce a number of problems associated with power generation technologies. For example, gas turbines combined with a backup battery provide contingency backup without burning fuel, and intermittent renewable resource problems can be mitigated by creating affordable large-scale energy storage. Thus, today there is no one perfect way to convert thermal energy into electricity, which could provide reliable and cost-effective electricity with minimal environmental impact.

Thermal power plants

At a thermal power plant, high-pressure and high-temperature steam, obtained from heating water by burning solid fuel (mainly coal), rotates a turbine connected to a generator. Thus, it converts its kinetic energy into electrical energy. Operating components of thermal power plant:

- Boiler with gas furnace.

- Steam turbine.

- Generator.

- Capacitor.

- Cooling towers.

- Circulating water pump.

- Feed pumpwater into the boiler.

- Forced exhaust fans.

- Separators.

Typical diagram of a thermal power plant is shown below.

The steam boiler is used to convert water into steam. This process is carried out by heating water in pipes with heating from fuel combustion. Combustion processes are continuously carried out in the fuel combustion chamber with air supply from outside.

Steam turbine transfers steam energy to drive a generator. Steam with high pressure and temperature pushes the turbine blades mounted on the shaft so that it begins to rotate. In this case, the parameters of superheated steam entering the turbine are reduced to a saturated state. The saturated steam enters the condenser, and the rotary power is used to rotate the generator, which produces current. Almost all steam turbines today are of the condenser type.

Condensers are devices for converting steam into water. The steam flows outside the pipes and the cooling water flows inside the pipes. This design is called a surface capacitor. The rate of heat transfer depends on the flow of the cooling water, the surface area of the pipes and the temperature difference between the water vapor and the cooling water. The water vapor change process occurs under saturated pressure and temperature, in this case the condenser is under vacuum, because the temperature of the cooling water is equal to the outside temperature, the maximum temperature of the condensate water is near the outside temperature.

The generator converts the mechanicalenergy into electricity. The generator consists of a stator and a rotor. The stator consists of a housing that contains the coils, and the magnetic field rotary station consists of a core that contains the coil.

According to the type of energy produced, TPPs are divided into condensing IESs, which produce electricity and combined heat and power plants, which jointly produce heat (steam and hot water) and electricity. The latter have the ability to convert thermal energy into electrical energy with high efficiency.

Nuclear power plants

Nuclear power plants use the heat released during nuclear fission to heat water and produce steam. The steam is used to turn large turbines that generate electricity. In fission, atoms split to form smaller atoms, releasing energy. The process takes place inside the reactor. In its center is the core, which contains uranium 235. Fuel for nuclear power plants is obtained from uranium, which contains the isotope 235U (0.7%) and non-fissile 238U (99.3%).

The nuclear fuel cycle is a series of industrial steps involved in the production of electricity from uranium in nuclear power reactors. Uranium is a relatively common element found all over the world. It is mined in a number of countries and processed before being used as a fuel.

Activities related to the production of electricity are collectively referred to as the nuclear fuel cycle for converting thermal energy into electrical energy at nuclear power plants. NuclearThe fuel cycle starts with uranium mining and ends with nuclear waste disposal. When reprocessing used fuel as an option for nuclear power, its steps form a veritable cycle.

Uranium-Plutonium Fuel Cycle

To prepare fuel for use at nuclear power plants, processes are carried out for the extraction, processing, conversion, enrichment and production of fuel elements. Fuel cycle:

- Uranium 235 burnup.

- Slag - 235U and (239Pu, 241Pu) from 238U.

- During the decay of 235U, its consumption decreases, and isotopes are obtained from 238U when generating electricity.

The cost of fuel rods for VVR is approximately 20% of the cost of electricity generated.

After the uranium has spent about three years in a reactor, the fuel used can go through another process of use, including temporary storage, reprocessing and recycling before waste disposal. Nuclear power plants provide direct conversion of thermal energy into electrical energy. The heat released during nuclear fission in the reactor core is used to turn water into steam, which spins the blades of a steam turbine, driving generators to generate electricity.

The steam is cooled by turning into water in a separate structure in a power plant called a cooling tower, which uses water from ponds, rivers or the ocean to cool the clean water of the steam power circuit. The chilled water is then reused to produce steam.

The share of electricity generation at nuclear power plants, in relation tothe overall balance of the production of their different types of resources, in the context of some countries and in the world - in the photo below.

Gas Turbine Power Plant

The principle of operation of a gas turbine power plant is similar to that of a steam turbine power plant. The only difference is that a steam turbine power plant uses compressed steam to turn the turbine, while a gas turbine power plant uses gas.

Let's consider the principle of converting thermal energy into electrical energy in a gas turbine power plant.

In a gas turbine power plant, air is compressed in a compressor. Then this compressed air passes through the combustion chamber, where the gas-air mixture is formed, the temperature of the compressed air rises. This high temperature, high pressure mixture is passed through a gas turbine. In the turbine, it expands sharply, receiving enough kinetic energy to rotate the turbine.

In a gas turbine power plant, the turbine shaft, alternator and air compressor are common. The mechanical energy generated in the turbine is partly used to compress the air. Gas turbine power plants are often used as a back-up auxiliary energy supplier to hydroelectric power plants. It generates auxiliary power during the start-up of the hydroelectric plant.

Advantages and disadvantages of gas turbine power plant

Designgas turbine power plant is much simpler than a steam turbine power plant. The size of a gas turbine power plant is smaller than that of a steam turbine power plant. There is no boiler component in a gas turbine power plant and hence the system is less complex. No steam, no condenser or cooling tower required.

Design and construction of powerful gas turbine power plants is much easier and cheaper, capital and operating costs are much less than the cost of a similar steam turbine power plant.

The permanent losses in a gas turbine power plant are significantly less compared to a steam turbine power plant, since in a steam turbine the boiler power plant must operate continuously, even when the system is not supplying a load to the network. A gas turbine power plant can be started almost instantly.

Disadvantages of a gas turbine power plant:

- The mechanical energy generated in the turbine is also used to drive the air compressor.

- Because most of the mechanical energy generated in the turbine is used to drive the air compressor, the overall efficiency of a gas turbine power plant is not as high as an equivalent steam turbine power plant.

- Exhaust gases in a gas turbine power plant are very different from a boiler.

- Before the turbine is actually started, the air must be pre-compressed, which requires an additional power source to start the gas turbine power plant.

- The gas temperature is high enough forgas turbine power plant. This results in a shorter system life than an equivalent steam turbine.

Due to its lower efficiency, the gas turbine power plant cannot be used for commercial power generation, it is usually used to supply auxiliary power to other conventional power plants such as hydroelectric power plants.

Thermionic converters

They are also called thermionic generator or thermoelectric motor, which directly convert heat into electricity using thermal emission. Thermal energy can be converted into electrical energy at very high efficiency through a temperature-induced electron flow process known as thermionic radiation.

The basic principle of operation of thermionic energy converters is that electrons evaporate from the surface of a heated cathode in a vacuum and then condense on a colder anode. Since the first practical demonstration in 1957, thermionic power converters have been used with a variety of heat sources, but all of them require operation at high temperatures - above 1500 K. While operation of thermionic power converters at a relatively low temperature (700 K - 900 K) is possible, the efficiency of the process, which is typically > 50%, is significantly reduced because the number of emitted electrons per unit area from the cathode depends on the heating temperature.

For conventional cathode materials such aslike metals and semiconductors, the number of electrons emitted is proportional to the square of the cathode temperature. However, a recent study demonstrates that the heat temperature can be reduced by an order of magnitude by using graphene as a hot cathode. The data obtained show that a graphene-based cathode thermionic converter operating at 900 K can achieve an efficiency of 45%.

Schematic diagram of the process of electron thermionic emission is shown in the photo.

TIC based on graphene, where Tc and Ta are the temperature of the cathode and the temperature of the anode, respectively. Based on the new mechanism of thermionic emission, the researchers suggest that the graphene-based cathode energy converter could find its application in the recycling of industrial waste heat, which often reaches the temperature range of 700 to 900 K.

The new model presented by Liang and Eng could benefit the graphene-based power converter design. Solid state power converters, which are mainly thermoelectric generators, usually operate inefficiently in the low temperature range (less than 7% efficiency).

Thermoelectric generators

Recycling waste energy has become a popular target for researchers and scientists who come up with innovative methods to achieve this goal. One of the most promising areas is thermoelectric devices based on nanotechnology, whichlook like a new approach to saving energy. The direct conversion of heat into electricity or electricity into heat is known as thermoelectricity based on the Peltier effect. To be precise, the effect is named after two physicists - Jean Peltier and Thomas Seebeck.

Peltier discovered that a current sent to two different electrical conductors that are connected at two junctions will cause one junction to heat up while the other junction cools down. Peltier continued his research and found that a drop of water could be made to freeze at a bismuth-antimony (BiSb) junction by simply changing the current. Peltier also discovered that an electric current can flow when a temperature difference is placed across the junction of different conductors.

Thermoelectricity is an extremely interesting source of electricity because of its ability to convert heat flow directly into electricity. It is an energy converter that is highly scalable and has no moving parts or liquid fuel, making it suitable for almost any situation where a lot of heat tends to go to waste, from clothing to large industrial facilities.

Nanostructures used in semiconductor thermocouple materials will help maintain good electrical conductivity and reduce thermal conductivity. Thus, the performance of thermoelectric devices can be increased through the use of materials based on nanotechnology, withusing the Peltier effect. They have improved thermoelectric properties and good absorption capacity of solar energy.

Application of thermoelectricity:

- Energy providers and sensors in ranges.

- A burning oil lamp that controls a wireless receiver for remote communication.

- Applying small electronic devices such as MP3 players, digital clocks, GPS/GSM chips and impulse meters with body heat.

- Fast cooling seats in luxury cars.

- Clean up waste heat in vehicles by converting it into electricity.

- Transforming waste heat from factories or industrial facilities into additional power.

- Solar thermoelectrics may be more efficient than photovoltaic cells for power generation, especially in areas with less sunlight.

MHD power generators

Magnetohydrodynamic power generators generate electricity through the interaction of a moving fluid (usually an ionized gas or plasma) and a magnetic field. Since 1970, MHD research programs have been carried out in several countries with a particular focus on the use of coal as a fuel.

The underlying principle of MHD technology generation is elegant. Typically, the electrically conductive gas is produced at high pressure by burning fossil fuels. The gas is then directed through a magnetic field, resulting in an electromotive force acting inside it in accordance with the law of inductionFaraday (named after the 19th century English physicist and chemist Michael Faraday).

The MHD system is a heat engine that includes the expansion of gas from high to low pressure in the same way as in a conventional gas turbine generator. In the MHD system, the kinetic energy of the gas is converted directly into electrical energy, as it is allowed to expand. The interest in generating MHD was initially sparked by the discovery that the interaction of a plasma with a magnetic field can occur at much higher temperatures than is possible in a rotating mechanical turbine.

The limiting performance in terms of efficiency in heat engines was set at the beginning of the 19th century by the French engineer Sadi Carnot. The output power of an MHD generator for each cubic meter of its volume is proportional to the gas conductivity product, the square of the gas velocity, and the square of the strength of the magnetic field through which the gas passes. In order for MHD generators to operate competitively, with good performance and reasonable physical dimensions, the electrical conductivity of the plasma must be in the temperature range above 1800 K (about 1500 C or 2800 F).

The choice of type of MHD generator depends on the fuel used and the application. The abundance of coal reserves in many countries of the world contribute to the development of MHD carbon systems for electricity generation.

Recommended:

Wastewater treatment from oil products: methods, methods and efficiency

At the moment, technologies and means, methods and units, thanks to which wastewater treatment from oil products is carried out, are among the most important means of ensuring environmental protection. In our country, for about five years now, legislatively fixed standards for the purification of liquids discharged by enterprises have been in force. Documentation on this issue establishes the quality and volume of water that can be produced by industrial facilities

Thermal imaging control of electrical equipment: concept, principle of operation, types and classification of thermal imagers, features of application and verification

Thermal imaging control of electrical equipment is an effective way to identify defects in power equipment that are detected without shutting down the electrical installation. In places of poor contact, the temperature rises, which is the basis of the methodology

What is an electrical substation? Electrical substations and switchgear

Trams and trolleybuses require voltage not alternating, but constant. This means that a separate very powerful substation is needed. Electrical energy is converted on it, that is, it is rectified

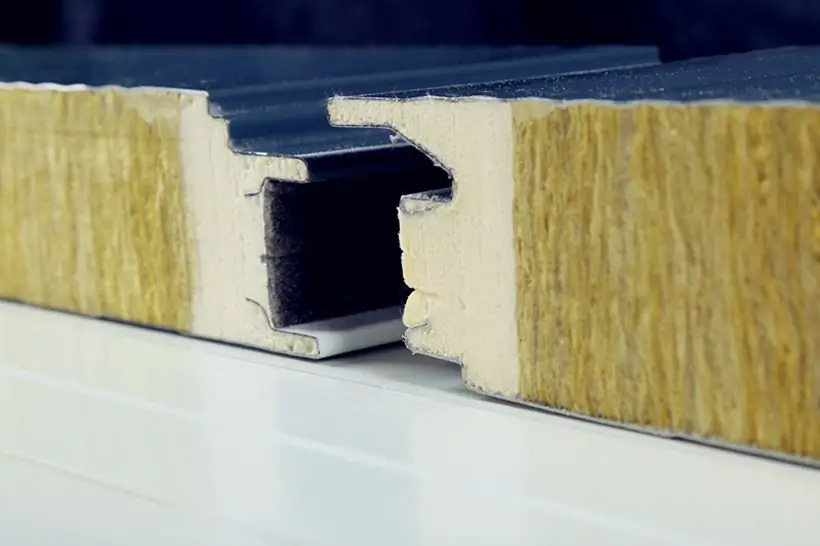

Thermal conductivity of sandwich panels: concept, main characteristics, dimensions, thickness, thermal conductivity coefficient, installation rules, pros and cons of operation

Thermal conductivity of sandwich panels will be the lowest if polyurethane foam is the basis. The parameter under consideration here varies from 0.019 to 0.25. The material is strong, dense and light. It is chemically resistant and does not absorb moisture. Rodents are indifferent to polyurethane foam, fungi and mold do not develop inside it. Working temperature reaches +160 ˚С

A conversion operation is Types of conversion operations. Conversion transactions

A conversion operation is a transaction carried out by participants in the foreign exchange market to exchange the currency of one state for the monetary unit of another. At the same time, their volumes are agreed in advance, as is the course with settlements after a certain time. If we consider the concept from a legal point of view, we can conclude that a conversion operation is a currency purchase and sale transaction