2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

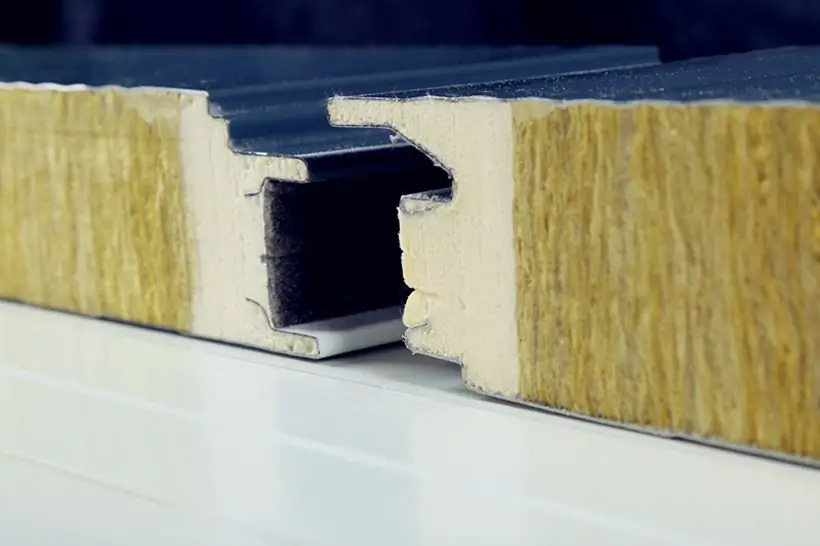

Sandwich panels today are considered a unique building material. When compared with classic solutions, the panels win in many respects. They are quite often compared in terms of characteristics with:

- concrete;

- gas silicate brick;

- brick;

- wood.

All these options lose in terms of thermal conductivity to sandwich panels.

The concept of thermal conductivity

Thermal conductivity is the ability of a material to conduct heat. This parameter is calculated according to a specific formula. It mentions the amount of heat that passes through a sample of material 1 m thick. Its area should be 1 m2. In this case, heat passes in one second at a unit temperaturegradient.

Absolute vacuum is the best thermal insulation material. Its thermal conductivity is zero. However, if in the production of thermoses it is possible to achieve a semblance of a cosmic vacuum, in construction one has to be content with one of the effective heat-insulating materials - air.

Thermal conductivity of panels with different heat-insulating layer. Key Features

In order to determine the thermal conductivity of sandwich panels, it is necessary to understand the base material. The coefficient of thermal conductivity will depend on this. For example, mineral wool with different densities has a thermal conductivity ranging from 0.38 to 0.7. The undoubted advantage of panels using mineral wool is fire safety. However, cotton wool has the ability to absorb water into itself, which contributes to the loss of heat-insulating characteristics. The material sags over time, among other things, such sandwich panels have a rather impressive weight.

The thermal conductivity of sandwich panels will be somewhat different if the basis is polystyrene foam. The thermal conductivity coefficient in this case will vary from 0.03 to 0.7, which depends on the density. The material does not absorb moisture, which is the main advantage of expanded polystyrene. But there are quite a few shortcomings here, among them low resistance to chemicals, brittleness, susceptibility to destruction at a temperature of 70 ˚С should be highlighted. In this regard, the material was assigned a fire resistance class G2. In addition, Styrofoam is lovedrodents. Under the influence of gasoline, acetone, the material melts and cannot resist oils.

Thermal conductivity of sandwich panels will be the lowest if polyurethane foam is the basis. The parameter considered here varies from 0.019 to 0.25. The material is strong, dense and light. It is chemically resistant and does not absorb moisture. Rodents are indifferent to polyurethane foam, fungi and mold do not develop inside it. The working temperature reaches +160 ˚С. The material belongs to the second class of fire resistance.

When you know the thermal conductivity of sandwich panels, you can consider the manufacturing method. For example, structures with expanded polystyrene and mineral wool are made by gluing technology, while polyurethane foam is foamed inside the panels, which allows to achieve a high-strength monolithic structure.

Heat engineering calculation

This calculation is required to select the type of sandwiches and their thickness. The formula is quite complicated, it takes into account the location of the house, the type of building, the average annual temperature, the design temperature inside the premises, the type of panels, the duration of the heating season, the relative humidity of the air inside. To take into account all these parameters is beyond the power of the layman. Yes, and a school course in physics will not be enough here. Therefore, heat engineering calculation has been used for quite a long time, where you need to know only the required value.

For example, for the European part of Russia, wall panels must have a minimum thicknessin 120 mm. This applies to polystyrene foam. If we are talking about mineral wool, this value increases to 150 mm. In the case of roof panels, these values will be 180 and 250 mm, respectively. This calculation is relevant for rooms where the air temperature should be equal to 20 ˚С. Thermal conductivity will be less if the panels have a less impressive thickness. However, in addition to thermal conductivity, there is also a coefficient of thermal resistance. It is also important to consider the heat transfer coefficient.

If the thermal conductivity of polyurethane foam insulation is 0.02, then this value will be maintained with a decrease in thickness to 80 or 60 mm. In the first case, the thickness is 100 mm. As for the coefficient of thermal resistance, it will decrease from 5 to 3. An intermediate value is 4. The heat transfer coefficient will increase. For thicknesses of 100, 80 and 60 mm, this parameter is 0.193; 0.24; and 0.315 respectively.

When performing thermal engineering calculations, you may also be interested in the thermal conductivity of sandwich panels for operating conditions. This indicator will be 0.034 at a temperature of 10 ˚С.

Thermal conductivity of Metal Profile products

Metal Profile Company supplies mineral wool sandwich panels to the market. The thermal conductivity of these products ranges from 0.046 to 0.048. The density is 110 kg/m3. The ultimate compressive strength is 55 kPa. You may also be interested in the coefficient of thermal conductivityinsulation sandwich panels "Metalprofile" if inside laid polystyrene foam. This indicator is 0.04 at 25 ˚С. The density here is 17 kg/m3. The compressive strength is 0.1 MPa. If the calculated thickness of the panels is greater than the maximum thickness of the manufactured products, the required size of the wall or roof should be filled with an additional layer of insulation.

When you know the coefficient of thermal conductivity of the insulation of sandwich panels "Metal Profile", you should also ask about the area of use of these products. They are designed to create internal and external walls, operated and non-operated ceilings, partitions and roofs. They can be used in new construction and in the reconstruction of objects for various purposes. These can be production and storage facilities, food and agricultural enterprises, building complexes, and so on. Products can be operated at temperatures from -65 to +85 ˚С.

Sizes of sandwich panels on the example of Metal Profile products

Before buying sandwich panels, you should ask about their dimensions. The minimum and maximum thicknesses are 50 and 250 mm, respectively. There is also such a thing as working width. It can be equal to 1000, 1160 and 1190 mm. Parameters other than those specified must be ordered separately. Length can vary from 2000mm to 14000mm.

Technical characteristics of polyurethane foam sandwich panels

Coefficient of thermal conductivitysandwich panels 100 mm will be 0.02. Work with such plates can be carried out at a temperature range from +5 to +30 ˚С. The service life reaches 30 years.

The material is resistant to aggressive environments and moisture. It is safe, which means it can be used in residential buildings. Operating temperature varies from -80 to +85 ˚С. Actual heat losses will be 1.7 times lower than the standard ones.

Installation rules

Installation of panels starts from the corner of the building. Installation is started from the base and continues in separate tiers, moving up from the bottom until the desired height of the building is reached. A 20 mm expansion joint is provided between the individual tiers. The support element of the base is installed on the plinth using an anchor dowel. If necessary, you can lay a layer of mineral wool.

The sandwich panel is lifted to a vertical position with a lifting device and placed on the plinth. Verticality must be checked with a surveying instrument or a plumb bob. The product is pressed against the purlins and fixed with hardware.

Pros and cons of exploitation

Sandwich panels are good because they can be operated in a wide temperature range from -65 to +85 ˚С. Products are environmentally friendly, durable and have a good locking connection with high reliability. The disadvantages of sandwich panels may lie in the insulation, which eventually becomes caked andabsorbs moisture. This applies to mineral wool, which is saturated with water and loses its performance characteristics. This may also apply to other thermal insulators that attract rodents and promote mold and mildew.

Recommended:

Thermal imaging control of electrical equipment: concept, principle of operation, types and classification of thermal imagers, features of application and verification

Thermal imaging control of electrical equipment is an effective way to identify defects in power equipment that are detected without shutting down the electrical installation. In places of poor contact, the temperature rises, which is the basis of the methodology

Solar panels on the roof: description, installation methods, principle of operation, reviews

Until recently, the use of sunlight as a replacement for traditional energy sources was perceived as something fantastic or possible only under special conditions. Today, such solutions do not look incredible, but the problems of their implementation in practice for ordinary consumers also remain. By itself, the installation of solar panels on the roof is quite simple and optimized, but this does not eliminate the difficulties in organizing the operation of such batteries

Extruded foam: specifications, thickness, density, thermal conductivity

The construction market today is overflowing with a variety of thermal insulation materials. They differ in production technology and their properties. However, one of the most popular is extruded foam, which will be discussed below

Thermal conductivity of concrete: features, coefficient and table

The thermal conductivity of concrete is determined by special formulas. For different types of material, this indicator may be different. Lightweight concrete retains heat better, heavy concrete worse

Railway track is Definition, concept, characteristics and dimensions. Train dimensions and features of track facilities operation

Traveling by train through cities and towns, you can learn a lot of interesting and amusing things about the world of the railway. More than once, traveling people have asked themselves questions about where this or that railway track leads? And what does the engineer who manages the train feel when the train is just starting off or arriving at the station? How and from where do metal cars move and what are the ways of the rolling stock?