2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:39

Gas block boiler house is a transportable installation of factory readiness. It can operate on the basis of gas boilers, the power range of which varies from 200 to 10,000 kW. The hot water circuit can optionally be installed additionally. The structures have the necessary documentation, after installation and connection they are completely ready for operation. Their main difference is that the system can be transported.

Description

Gas block boiler is an installation that is supplied by the consumer in full factory readiness, with all the necessary certificates and documents. Gas boiler plants are a modern solution for heating office buildings, production workshops, residential complexes and other facilities for various purposes. A block boiler house is a device that is distinguished by efficiency and high power, as well as transportability and comfort of operation.

The installation is capable of performing several tasks at once, among them it is worth highlighting:

- hot water;

- heating;

- ventilation.

Among other things, the consumer purchases ready-to-install boiler units. The advantages of such boiler houses are the availability of certificates and permits, factory readiness, automatic operation, as well as a wide range of boiler rooms. The consumer benefits and saves on design work, he will be able to obtain different permits without much difficulty. The terms of construction of the boiler house can be significantly reduced, it will be possible to reduce the cost of design and installation work. If the consumer chooses such a block boiler house, then he will be able to reduce the cost of on-duty personnel, significantly increasing the convenience of work.

For reference

On sale you can find modular boiler rooms in a large assortment, they may have the necessary equipment and power. Among other things, they are economical. The use of boiler houses reduces heating costs, because the price of 1 kW of thermal energy produced by a boiler house will be lower compared to that offered by central heating systems.

Additional Features

Modular block boiler room is a device that is completely ready for installation on the foundation, which is why it is possible to bring transportation to the object already assembled. The consumer will only have to connect it to the gas pipeline system and heating. Capital construction costs will be eliminated, approval work will be cheaper, because suchproducts require compliance with specifications.

Boilers can be combined into a cascade, while increasing capacity. The devices are lightweight, so they can be placed even on the surface of the roof of buildings. Their compact size attracts the attention of consumers; this distinguishes these devices from stationary boiler houses. They can be produced in the form of ready-to-use products. Installation will require a minimal package of permissions, automation is guaranteed to be complete, so maintenance of the installation is not required. If necessary, the boiler room can be dismantled from its current location for use at another facility.

Specifications

Block gas boilers have certain characteristics, including the use of gas as the main fuel, as well as the usual type of combustion. The heat exchanger used is tubular and made of steel. It will be possible to control the operation of such a boiler house using an electronic block device. Gas supply is automatic.

Design features

The main technological equipment used in modular boiler houses is the steam or hot water boiler itself. Heat exchangers and a burner are used. For gas block boilers, gas equipment is used, which includes a filter, a gas pressure regulator, and emergency valves. not excludedand gas metering units and valves.

A block boiler plant must contain pumping equipment, these can be network or circulation pumps, feed, make-up, and anti-condensate pumps. Appropriate equipment is used for water treatment and water purification, and in the presence of hot water supply, circuit equipment is used. For the correct functioning of the system, control and measuring equipment is used, with the help of which the system records temperature, electricity, steam, water and other parameters. The presence of chimneys and flues is important.

Working principle

In boiler installations, water is heated by the heat that is obtained from the combustion of fuel. The resulting heat heats the liquid that circulates in the heat exchanger. Pumping equipment is necessary to supply water for feed pumps, and appropriate equipment is used to circulate water in the heating system, which distills liquid from the boiler room to the consumer and back. This involves circulation and network pumps.

During the combustion process, combustion products can be formed, they are removed outside through chimneys or gas ducts, entering the atmosphere. In order to prevent the formation of scale and ensure the normal operation of the hydraulic system, it is necessary to purify water from mechanical impurities. For this, boiler plants can have a deaerator, as well as cleaning filters. If there is equipment forwater treatment, this significantly extends the life of the equipment, reducing the risk of its failure. Membrane or expansion tanks are required in the boiler room to pressurize the liquid and maintain the pressure in the system. They are needed to prevent water hammer.

Minimum equipment for a gas boiler

Production of block boilers provides for compliance with one of three configurations. If we are talking about the minimum, then gas boilers made of steel are supplied in the amount of two pieces, this also applies to boiler pumps. But the circulation pump is used in a single copy, as well as a chemical water treatment plant. The same applies to each of the following components: a membrane tank, a commercial metering unit for water, electricity and gas, a modular boiler house building, a control panel for a security and fire alarm, control and shutoff valves.

Conclusion

There are special companies that are engaged in the design, manufacture and installation, as well as commissioning of the equipment described in the article. This includes "Block boiler technologies", which are engaged in the manufacture of block power plants in a separate building or as part of an energy complex. Typical solutions are well-established and favorably distinguish the company from alternative manufacturers in this segment. Typical options affect the timing and cost of the final product in a smaller direction, which is very welcome by consumers.

Recommended:

Gas production. Gas production methods. Gas production in Russia

Natural gas is formed by mixing various gases in the earth's crust. In most cases, the depth of occurrence ranges from several hundred meters to a couple of kilometers. It is worth noting that gas can form at high temperatures and pressures. In this case, there is no access of oxygen to the place. To date, gas production has been implemented in several ways, each of which we will consider in this article. But let's talk about everything in order

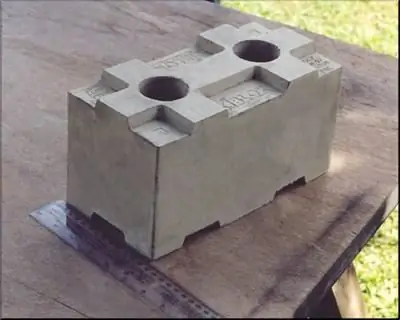

Foam block: foam block dimensions, history of appearance and application prospects

Each movement of the bricklayer is performed at a certain speed. An ordinary clay brick weighing about 3 kg or a large foam block of the same mass will be installed in the wall in the same time. But the dimensions of the foam block are eight or even twelve times the size of a brick, which dramatically increases the speed of masonry. Another important advantage of a light and warm building material is that it requires an adhesive rather than a complex cement-sand mortar

Characteristics of the Su-35. Su-35 aircraft: specifications, photo of the fighter. Comparative characteristics of the Su-35 and F-22

In 2003, the Sukhoi Design Bureau began the second in line modernization of the Su-27 fighter to create the Su-35 aircraft. The characteristics achieved in the process of modernization make it possible to call it a 4++ generation fighter, which means that its capabilities are as close as possible to the PAK FA fifth generation aircraft

Facing block: types, classification, characteristics, selection tips, advantages and disadvantages of application

Today, there are many different materials for construction. Facing block is one of them. It has recently been used quite often due to its unique characteristics. It is worth noting that this material allows you to save a significant amount of material resources

Boiler room operator: job description, ranks

The boiler room operator belongs to the category of workers and reports to the foreman or the shift supervisor, in some cases his leadership is the head of the structural unit. To obtain this position, he must obtain the necessary qualifications and be instructed at the enterprise