2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:30

If before the EDM machine was a rarity, today such equipment is no longer a surprise. Electroerosion is understood as the destruction of interatomic forces of interaction in metals under the influence of an electric charge. The electroerosive machine owes its appearance to the developments of Soviet scientists B. R. Lazarenko and N. I. Lazarenko. Such equipment is universal. It allows you to process and shape any grade of metals and alloys. Moreover, the hardness of the material being processed does not matter. The ability to machine any material is one of the main advantages of EDM over traditional machining.

The principle of operation of the EDM machine

When getting acquainted with the principle of operation of such equipment, many haveassociation with arc welding. And this is quite logical. After all, for the course of erosion processes, it is necessary to obtain an electric discharge. For this purpose, a potential difference is created between the electrodes. In this case, one of the electrodes is the workpiece, and the second is the machine electrode.

When the electrode approaches the workpiece at a critical distance, the so-called breakdown occurs. In other words, the electrons do the work function and rush through the air to the cathode (workpiece).

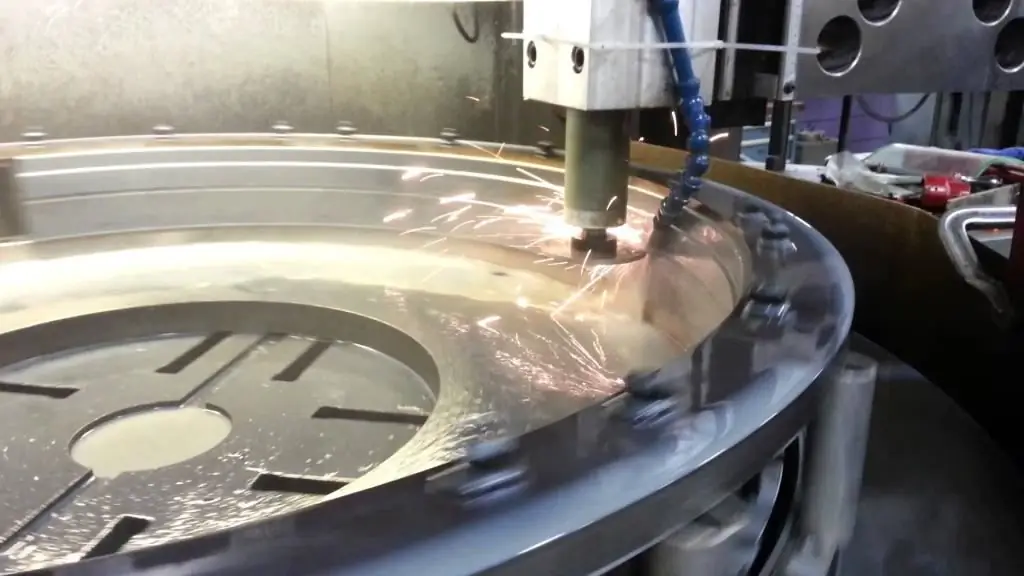

Electrons, colliding with the surface of the workpiece, heat it up to incredibly high temperatures (10,000 degrees Celsius or more) in a matter of seconds. The melting point of even the most refractory materials is several times lower. Thus, the metal layer instantly evaporates, depressions are formed according to the shape of the working tool of the EDM machine.

Why do I need an electrolyte?

To enhance the effect, the anode and cathode are placed in a dielectric solution. As such, kerosene can be used. However, it can ignite at any moment. Therefore, preference should be given to special mineral oils. Oil can also burn, but flash points are much higher than those of kerosene. In addition, kerosene emits fumes harmful to production personnel.

The dielectric liquid heats up strongly and forms a so-called steam jacket (small air bubbles). It is through air enclosed in a dielectric liquid, andcurrent flows (directional movement of electrons). This allows you to concentrate the flow of electrons and enhance the beneficial effect.

Influence of processing on the strength characteristics of the machined surface

After processing, the chemical composition and concentration of various elements in the near-surface layer of the workpiece change somewhat. For example, the concentration of carbon may increase. In addition, the surface layer can be doped with elements that were contained in the molten electrode. By selecting electrodes, it is possible to alloy the surface with elements such as aluminum, zinc, chromium, nickel, tungsten and others. Depending on the conditions of subsequent operation of the part, this can play both a positive and a negative role.

Advantages of EDM technology and equipment

One of the main advantages of this technology is the very high precision of product processing. This led to the widespread use of EDM technology in such industries as the military industry, precision engineering, as well as in the production of critical medical products.

Lack of production space is one of the main problems of modern engineering companies. EDM machines are usually quite compact and can partially solve this problem. Thus, the compactness of the equipment is also an indisputable advantage of machines of this type.

DeviceEDM machine

There are many types of machine tools. However, the above principles of operation are absolutely valid for each of them, whether it is an electroerosive piercing machine or a machine for electrospark processing.

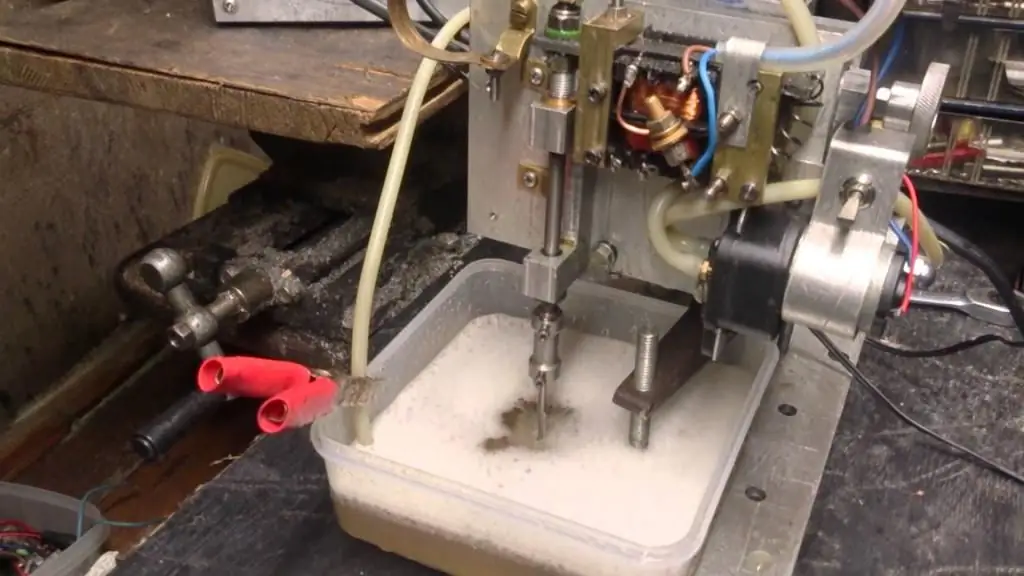

It may seem that this process equipment is incredibly complex and expensive. Expensive, perhaps. Especially if the machine produces a famous brand. However, the principle of operation of the equipment is quite simple. A lot of videos have appeared on the Web in which craftsmen reproduce these processes. Moreover, they assemble electroerosive machines with their own hands in home amateur workshops.

The machine itself, like any other machine for processing metals and other materials, includes a frame (base), an electrolyte bath, a spindle head, a control panel for the operator (it can also be a full-fledged numerical control system), various automation. These are the main components. Some machines can be additionally equipped with an electrolyte filtration system and other devices.

Recommended:

Shot blasting machine: principle of operation

The article is devoted to shot blasting machines. The principles of operation of various units of this type, the main characteristics, features of the device, etc

Electric locomotive 2ES6: history of creation, description with photo, main characteristics, principle of operation, features of operation and repair

Today, communication between different cities, passenger transportation, delivery of goods is carried out in a variety of ways. One of these ways was the railroad. Electric locomotive 2ES6 is one of the types of transport that is currently actively used

Regenerative heat exchangers: types, principle of operation, scope

The principle of heat exchange using heated circulating media is considered optimal for maintaining the operation of heating systems. A properly organized system of thermal energy transfer channels requires minimal maintenance costs, but at the same time provides sufficient performance. An optimized design option for such a system is a regenerative heat exchanger that provides alternate heating and cooling processes

Low pressure heaters: definition, principle of operation, technical characteristics, classification, design, operation features, application in industry

Low pressure heaters (LPH) are currently used quite actively. There are two main types that are produced by different assembly plants. Naturally, they also differ in their performance characteristics

Gas piston power plant: the principle of operation. Operation and maintenance of gas piston power plants

Gas piston power plant is used as a main or backup source of energy. The device requires access to any type of combustible gas to operate. Many GPES models can additionally generate heat for heating and cold for ventilation systems, warehouses, industrial facilities