2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

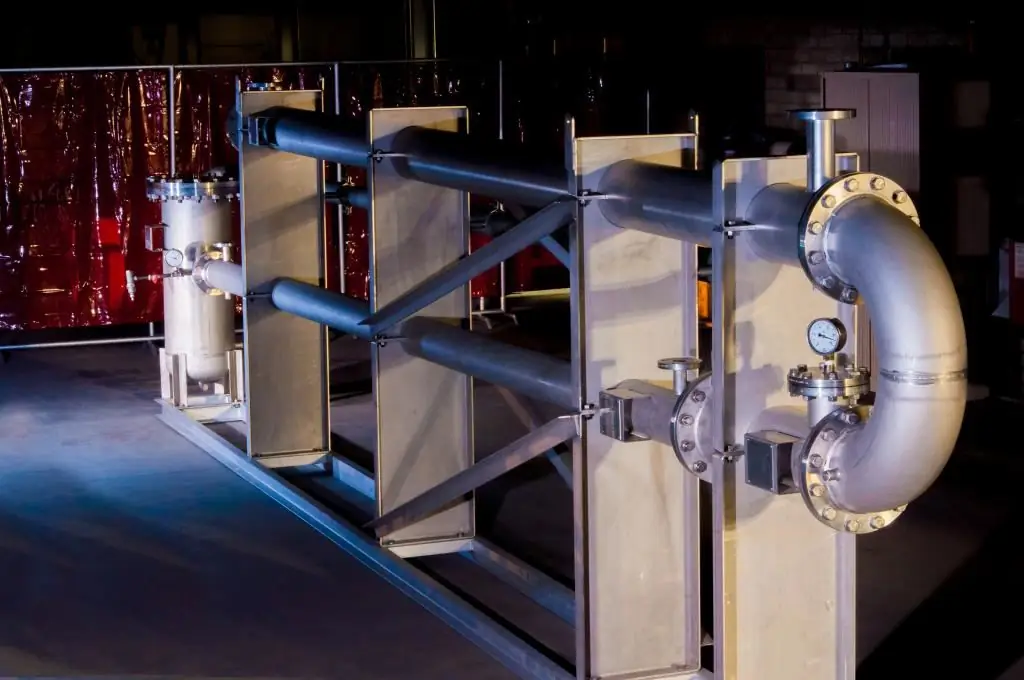

The principle of heat exchange using heated circulating media is considered optimal for maintaining the operation of heating systems. A properly organized system of thermal energy transfer channels requires minimal maintenance costs, but at the same time provides sufficient performance. An optimized design option for such a system is a regenerative heat exchanger that provides alternate heating and cooling processes.

What is a heat exchanger?

The designs of modern heat exchangers provide processes for transferring thermal energy with minimal losses between operating media. The exchange most often occurs between a hot liquid and cold metal surfaces, the walls of which, in turn,turn, transfer heat to another circulating medium. Constant movement provides the effect of a stable mass transfer, which is used both in industrial enterprises and in the domestic service of private houses. In addition to energy exchange between cold and hot media, heat exchangers can provide the processes of evaporation, drying, melting and condensation with cooling. Instead of heat as the main working medium, cold streams can also be used, which is especially common in production processes where periodic cooling of equipment is required. However, heating tasks are more likely to be associated with heat exchanger designs. For example, high-temperature equipment of this type can increase the thermal regime up to 400-700 °C.

Features of the regenerative heat exchanger

Designs of heat exchangers at the basic level are divided into surface and mixing. In this case, we are talking about a representative of a group of surface devices, which are characterized by the fact that two active media (heated and cold flows) and a metal wall are involved in the working process, which transfers energy between the circulating masses. In a regenerative heat exchanger, the separation metal plate is flushed at regular intervals, but not continuously. For comparison, we can give an example of another surface heat exchanger - recuperative. In such devices, the working process involves constant washing of a similar wall with cold or heatedflows.

The principle of operation of the device

The main function of the heat exchanger is performed at the moment of contact of the active working medium with a metal plate that separates the flows. That is, the key principle of operation is the accumulation of energy from a liquid that currently has a different temperature than the heat exchanger wall. Roughly speaking, in the first cycle of operation, hot streams transmit and thereby retain heat in the metal element, and in the second and final cycle, the already cold environment perceives this heat. The accumulative principle of operation of the heat exchanger with a clear separation into media according to temperature has significant advantages. First, the absence of the need for mixing of working media improves the quality of the composition of the streams. This is an important factor in the technical and operational content of communications. Secondly, the efficiency of heat transfer as such is also increased. On the other hand, these advantages are inextricably adjacent to the disadvantages of the design. The fundamental separation of flows increases the dimensions of the equipment, sometimes forcing the extension of pipeline segments in old communication heating networks. In addition, ensuring the circulation function requires an increase in the energy potential, which is expressed in the need to connect high-capacity pumping stations.

Used coolants

Regenerative heat exchanger models are versatile in terms of serviceability for differentworking environments. As with other heat exchangers, the most common active medium is a liquid-water or antifreeze. The coolants used in technological operations in production are more diverse. Water vapor, gas mixtures, smoke and flue products of combustion are used for heating and cooling. However, this does not mean at all that the same regenerative heat exchanger can support operation with different heat carriers. In principle, the design allows for such a theoretical possibility, but each instance must initially be designed for operation in contact with a certain aggressive environment, since both high temperatures and the liquid as such negatively affect the metal structure.

Types of regenerative heat exchangers

There are two types of such units. These are devices with continuous and periodic action. Continuous heat exchangers are units with granular circulating filler. The control system for the process of moving the working medium allows a complete stop of movement, in which the coolant will maintain contact with the washed surface. By the way, the function of a natural automatic regulator can be performed by special thermal storage nozzles. In the design of a regenerative heat exchanger with fixed nozzles, the possibilities for controlling flows are limited and completely dependent on the settings set by the operator. As for models with periodic action, theyhave a complicated distribution structure of chambers with heat carriers. Such a device increases the efficiency of the apparatus, but also requires a more responsible power supply function from the circulation pump.

Fusible core heat exchangers

One of the most advanced versions of the heat exchange regenerator at the moment, the packing of which is formed by platelets with an average thickness of 20 mm. In this system, there is a melting core - a device with liquid metal inside, which releases thermal energy during periods of melting or crystallization. Latent heat in regenerative heat exchangers with a movable nozzle increases the heat capacity of the circuit tenfold compared to conventional units that create favorable conditions for heat accumulation processes. The performance of this type of high-temperature heat exchanger will be determined by the specific surface area of the packing and its thermal storage capacity.

Scope of equipment

Heat exchange units are widely used in various systems of heating equipment with boiler installations, water heaters, storage tanks, boilers, etc. This applies mainly to the private segment, but the highest technical and operational indicators of this device are disclosed in the industrial sector. For example, the target applications for a regenerative batch heat exchanger are formed by steel and glass plants, where it is required to work withvery high temperatures. For example, connected air heaters under such operating conditions are designed for modes up to 1300 °C. And again, we can talk not only about liquid media, but also about gas mixtures, which increases the safety requirements for the operation of such units.

Conclusion

The regenerative modification of the heat exchanger has been developed to optimize a number of thermal processes. As a result, at the same industrial facilities today it is possible to carry out technological processes with minimal fuel consumption, while maintaining a high combustion temperature. But this does not mean at all that the principle of operation of a heat exchanger with an accumulative function is completely devoid of disadvantages. The weak points of this equipment include the limited possibilities of automating the heat engineering process, the large size and weight of the apparatus, as well as the difficulty of connecting the structure to the main production communications. Another thing is that the design of the regenerator is constantly being improved, as evidenced by the emergence of more advanced models of heat exchangers with a fusible core.

Recommended:

Electroerosive machine: scope and principle of operation

If before the EDM machine was a rarity, today such equipment is no longer a surprise. Electroerosion is understood as the destruction of interatomic forces of interaction in metals under the influence of an electric charge. The electroerosive machine owes its appearance to the developments of Soviet scientists B. R. Lazarenko and N. I. Lazarenko. Such equipment is universal. It allows you to process and shape any grade of metals and alloys

Electric locomotive 2ES6: history of creation, description with photo, main characteristics, principle of operation, features of operation and repair

Today, communication between different cities, passenger transportation, delivery of goods is carried out in a variety of ways. One of these ways was the railroad. Electric locomotive 2ES6 is one of the types of transport that is currently actively used

Types of heat transfer: heat transfer coefficient

Because the heat of different substances may differ, there is a process of transferring heat from a hotter substance to a substance with less heat. This process is called heat transfer. We will consider the main types of heat transfer and the mechanisms of their action in this article

Heat treatment of alloys. Types of heat treatment

Heat treatment of alloys is an integral part of the production process of ferrous and non-ferrous metallurgy. As a result of this procedure, metals are able to change their characteristics to the required values. In this article, we will consider the main types of heat treatment used in modern industry

Differential pressure gauge: principle of operation, types and types. How to choose a differential pressure gauge

The article is devoted to differential pressure gauges. The types of devices, the principles of their operation and technical features are considered