2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:37

Geomembrane is a modern roll of polymeric materials, the thickness of which can vary from 1 to 4 mm. They are made of polyethylene, polypropylene, polyvinyl chloride and other materials with a minimum thickness of 0.5 mm. As for its width, it can be up to 7 m, and the main performance feature is that the geomembrane is completely waterproof. This expands the scope of its use, which, among other things, will be discussed below.

Properties

Today, HDPE geomembrane is very common, what it is will be described in the article. Modern geomembranes based on polyethylene can have a textured or smooth surface. This will allow you to take advantage of the opportunity to choose when performing a particular kind of work. Among the main characteristics of such a material, high waterproofing qualities can be distinguished. Such materials have high physical and mechanical properties, which makes them universal. When they come into contact with liquids, the diffusion process can only occur at the molecular level. By the way, it can be noted that the material canbe used in direct contact with potable water. Geomembranes are resistant to chemicals, they are non-shrinking, flexible, and also do not crack and perfectly withstand various kinds of impacts without being damaged. The material elongates under load up to 850%, and its tensile strength can be 26.2 MPa.

Durability

If you are interested in HDPE geomembrane, what it is, you should definitely find out. This material is resistant to solar radiation, temperature changes, and can also be used in seismically hazardous areas. It is puncture resistant and can be used for a wide range of applications. Geomembranes can be used in all climatic zones. If the rules of professional installation are followed, the service life of the geomembrane can reach 90 years.

Use area

Recently, HDPE geomembrane has been increasingly used. What is it, before purchasing it, you should definitely ask. This material has excellent physical and chemical characteristics, which makes it possible to use storage liquid and solid wastes in the construction of impervious screens, including toxic substances. The geomembrane is successfully used in the arrangement of reservoirs, landfills, manure storage facilities, as well as for anti-corrosion waterproofing coating of metal, concrete and other structures, and in the processoperation may interact with drinking water. On sale you can find several varieties of HDPE geomembrane: Solmax 840, 860 and 880. Each of these materials has its own characteristics of certain indicators. For example, the minimum average thickness in the first case is 1 mm, while in the second and third cases it is 1, 5 and 2 mm, respectively. Roll size is 6.8x238; 6.8x159; 6.8x122mm respectively for each of the above varieties.

Density

The density of the material in all three cases is the same and can start at 0.926 g/cm². As for the density of the membrane, it can be equal to 0.939 g / cm², sometimes this value is greater. The content of soot in it can vary from 2 to 3%. The stress of the material at relative elongation can be equal to 14.7; 22 or 29% respectively.

Additional properties

Professional builders and home craftsmen use HDPE geomembrane - what is it, you should ask before visiting the store. This material has many advantages, among them - versatility, cost-effectiveness, high manufacturability of installation, efficiency, and environmental friendliness. The functional qualities of the geomembrane provide a demand for the construction of structures for the storage of waste of different hazard classes. Such geomembranes are successfully used in landscape and hydraulic engineering construction. The material is economical, its use reduces the cost ofoperation and construction. No matter what the area of use, the use of a geomembrane reduces the amount of work, the amount of materials and allows you to complete the project in the shortest possible time. HDPE geomembrane is also famous for its high manufacturability. It lies in the fact that with a width of 7 m, the need for seams that are performed by welding equipment is reduced. Thus, the craftsmen do not need to manually sew the seams at the joints of the panels.

Geomembrane is very durable and reliable in operation. The techniques have been worked out, and the quality is on top. Among other things, the material is completely environmentally friendly. It is used in the arrangement of environmental facilities. Based on the technical specifications, it is possible to guarantee reliable insulation of structures, which excludes the diffusion of pollution sources.

Application features: preparatory stage

HDPE (polyethylene) should be laid on a pre-prepared base, which is previously cleaned of stones, debris, organics and other materials that could damage the canvas. It also happens that the surface does not meet the listed requirements, in these cases it is recommended to use an underlying protective layer, which consists of needle-punched textiles. It is important to take measures that would exclude the possibility of the formation of areas of accumulation of liquid on the surface of the underlying layer.

Laying material

Based ongeotextile - HDPE. HDPE must be laid according to certain rules that do not contradict the nature of this material. It is necessary to start work after drawing up an installation plan. At the same time, the dimensions and relative position of the canvases, as well as welding seams, are indicated in detail. Installation work should provide for the observance of certain points, among them - the direction and sequence of installation, the designation of canvases and welds, the location of structures according to the type of pipe outlets and connection to existing buildings. Sheets should be arranged in such a way that the seams are not crossed at one point. The minimum spacing between the crossing points should be 0.5 m. HDPE (high density polyethylene - at the base of the material) should be laid with overlapping widths ranging from 100 to 150 mm. It is necessary to adhere to this rule in the transverse and longitudinal directions. The craftsman must take care of the minimum number of extrusion welds.

On slopes, the material must be laid from top to bottom, using special devices called traverses. To fix the geomembrane on the upper edge of the slope, anchor trenches should be provided. If there is a need to strengthen the geomembrane to the concrete surface, then special fasteners should be prepared, these can be pressure plates and dowels, geomembrane strips. The latter should be attached in advance to the concrete surface with dowels. As fasteners can act andembedded parts.

Welding tips

Whatever geomembrane you use - HDPE 1.5 mm or any other thickness, welding of seams must be carried out using special equipment that produces hot air. An alternative option may be a hot wedge or a combined method. The last option allows you to make two seams that will have a test channel. Subsequently, it will be possible to control the quality of the welded joint. If you have to work in hard-to-reach places or areas of engineering communications, then it is best to use extrusion welding technology.

Instead of a conclusion

The density of HDPE, which was mentioned above, may be of interest not only to professionals in their field, but also to experienced home craftsmen who plan to use this material in their work. Among other things, you may be interested in some of the unique properties of geomembranes. Among them, it is also worth highlighting the inertness with respect to alkalis and acids, which have a pH in the range of 1.5 to 14. As practice shows, aging does not occur during thermal exposure, but the standard guarantee for the material with self-laying is 75 years.

Recommended:

Combustible gases: names, properties and applications

Combustible gases - hydrocarbons formed in the earth's crust as a result of thermal decomposition of organic residues. They are highly economical energy fuels

Polyols are polyhydric alcohols (polyalcohols): properties, production and applications

Polyols - safe or not? What are polyalcohols, why are they included in the composition of chocolate, chewing gum, foam rubber and antifreeze. The most famous polyols are sweeteners. Production of polyhydric alcohols in Russia and abroad

Platinum group metals: overview, list, properties and applications

Platinum group metals are six noble precious chemical elements that are located side by side in the periodic table. All of them are transition metals of 8–10 groups of 5–6 periods

What is sapphire crystal? Properties, comparisons and applications

Methods for obtaining ordinary glass have been known for a long time. The technology has remained virtually unchanged even in the modern world. So what is sapphire crystal?

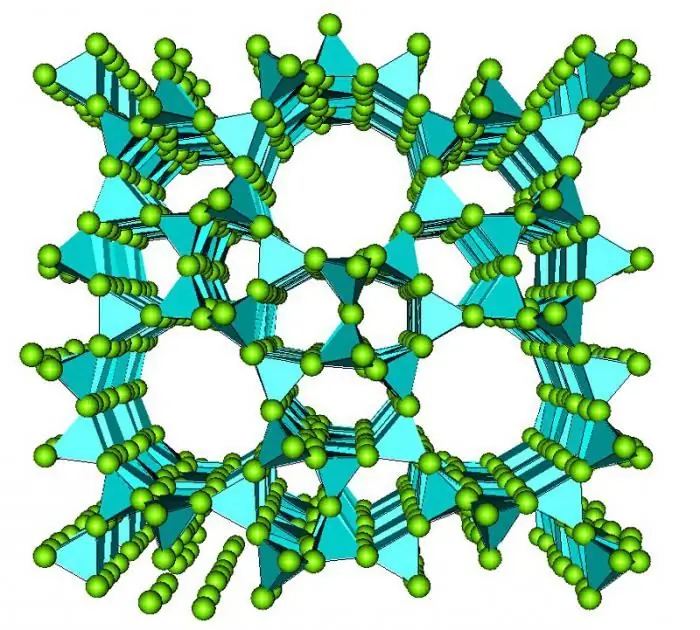

Zeolite - what is it? Zeolite natural and synthetic. Zeolite: properties, applications, benefits and harms

Its name translates as "boiling stone". It is impossible to count the uses of this seemingly simple mineral. It can even be eaten and used as a sieve for molecules. Such a versatile and useful zeolite