2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-06-01 07:12:56

Platinum group metals are six noble precious chemical elements that are located side by side in the periodic table. All of them are transition metals of 8-10 groups of 5-6 periods.

Platinum group metals list

The group consists of the following six chemical elements, arranged in ascending order of atomic weight:

- Ru - ruthenium.

- Rh - rhodium.

- Pd - palladium.

- Os - osmium.

- Ir - iridium.

- Pt - platinum.

Platinum group metals have a silvery white tint, except for osmium, which is bluish white. Their chemical behavior is paradoxical in that they are highly resistant to most reagents but are used as catalysts, easily accelerating or controlling the rate of oxidation, reduction and hydrogenation reactions.

Ruthenium and osmium crystallize into a hexagonal close-packed system, while others have a face-centered cubic structure. This is reflected in the greater hardness of ruthenium and osmium.

Discovery history

Although platinum-bearing gold artifacts date back to 700 BC. e., the presence of this metal is more an accident than a pattern. Jesuits in the 16th century mentioned gray, dense pebbles associated with alluvial gold deposits. These stones could not be melted, but they formed an alloy with gold, while the ingots became brittle, and it was no longer possible to clean them. The pebbles became known as platina del Pinto, granules of silvery material from the Pinto River, which flows into the San Juan River in Colombia.

Malleable platinum, which can only be obtained after complete purification of the metal, was isolated by the French physicist Chabano in 1789. From it was made a goblet presented to Pope Pius VI. The discovery of palladium in 1802 was reported by the English chemist William Wollaston, who named the chem. element of the platinum metal group in honor of the asteroid. Wollaston subsequently claimed to have discovered another substance present in platinum ore. He called it rhodium because of the pink color of the metal s alts. The discoveries of iridium (named after the rainbow goddess Iris because of the variegated color of its s alts) and osmium (from the Greek word for "smell" because of the chlorine smell of its volatile oxide) were made by the English chemist Smithson Tennant in 1803. French scientists Hippolyte-Victor Collet-Descoti, Antoine-Francois Fourcroix, and Nicolas-Louis Vauquelin isolated the two metals at the same time. Ruthenium, the last isolated and identified element, received its name from the Latin name for Russia from the Russian chemist Karl Karlovich Klaus in 1844.

Unlikefrom such easily isolated in a relatively pure state by simple fire refining substances such as gold, silver, platinum group metals require complex water-chemical treatment. These methods were not available until the late 19th century, so the identification and isolation of the platinum group lagged behind silver and gold by thousands of years. In addition, the high melting point of these metals limited their use until researchers in Britain, France, Germany and Russia developed methods for converting platinum into a workable form. How the precious metals of the platinum group began to be used in jewelry since 1900. Although such applications remain relevant today, the industrial one has far surpassed it. Palladium became a highly sought-after contact material in telephone relays and other wired communication systems, providing long life and high reliability, while platinum, due to its resistance to spark erosion, was used in combat aircraft spark plugs during World War II.

After the war, the expansion of molecular conversion techniques in petroleum refining created a huge demand for the catalytic properties of the platinum group metals. By the 1970s, consumption increased even more when automobile emission standards in the US and other countries led to the use of these chemicals in catalytic exhaust gas conversion.

Ores

Excluding small placer deposits of platinum, palladiumand osmic iridium (an alloy of iridium and osmium), there is practically no ore in which the main component would be a chemical element - a platinum group metal. Minerals are usually found in sulfide ores, in particular pentlandite (Ni, Fe)9S8. The most common are laurite RuS2, irarsite, (Ir, Ru, Rh, Pt)AsS, osmiridium (Ir, Os), cooperite, (PtS) and braggite (Pt, Pd)S.

The world's largest deposit of platinum group metals is the Bushveld complex in South Africa. Large reserves of raw materials are concentrated in the Sudbury deposits in Canada and the Norilsk-Talnakhskoye deposit in Siberia. In the USA, the largest deposits of platinum group minerals are located in Stillwater, Montana, but here they are much smaller than in South Africa and Russia. The world's largest platinum producers are South Africa, Russia, Zimbabwe and Canada.

Extraction and enrichment

The main South African and Canadian deposits are operated by the mine method. Virtually all platinum group metals are recovered from copper or nickel sulfide minerals using flotation separation. Smelting the concentrate produces a mixture that is washed out of the copper and nickel sulfides in an autoclave. Solid leach residue contains 15 to 20% platinum group metals.

Sometimes gravity separation is used prior to flotation. The result is a concentrate containing up to 50% platinum metals, eliminating the need for smelting.

Mechanical properties

Metals of the platinum group differ significantly in mechanical properties. Platinum and palladium are quite soft and very malleable. These metals and their alloys can be worked both hot and cold. Rhodium is first worked hot and can later be cold worked with fairly frequent annealing. Iridium and ruthenium must be heated, they cannot be cold worked.

Osmium is the hardest of the group and has the highest melting point, but its tendency to oxidize imposes its own limitations. Iridium is the most corrosion resistant of the platinum metals, and rhodium is prized for its high temperature retention.

Structural applications

Because clean annealed platinum is very soft, it is susceptible to scratches and deterioration. To increase its hardness, it is alloyed with many other elements. Platinum jewelry is very popular in Japan where it is called "hakkin" and "white gold". Jewelry alloys contain 90% Pt and 10% Pd, which is easy to machine and solder. The addition of ruthenium increases the hardness of the alloy while maintaining oxidation resistance. Alloys of platinum, palladium and copper are used in forgings because they are harder than platinum palladium and are less expensive.

Crucibles used for the production of single crystals in the semiconductor industry require corrosion resistance and stability at high temperatures. For this application, platinum, platinum-rhodium andiridium. Platinum-rhodium alloys are used in the manufacture of thermocouples, which are designed to measure elevated temperatures up to 1800 °C. Palladium is used both in pure and mixed form in electrical devices (50% of consumption), in dental alloys (30%). Rhodium, ruthenium and osmium are rarely used in their pure form - they serve as an alloying additive for other platinum group metals.

Catalysts

About 42% of all platinum produced in the West is used as a catalyst. Of these, 90% is used in automotive exhaust systems, where platinum (as well as palladium and rhodium) coated refractory pellets or honeycombs help convert unburned hydrocarbons, carbon monoxide and nitrogen oxides into water, carbon dioxide and nitrogen.

An alloy of platinum and 10% rhodium in the form of a red-hot metal mesh catalyzes the reaction between ammonia and air to produce nitrogen oxides and nitric acid. When fed together with a mixture of ammonia, methane hydrocyanic acid can be obtained. In petroleum refining, platinum on the surface of alumina pellets in the reactor catalyzes the conversion of long chain oil molecules into branched isoparaffins, which are desirable in high octane gasoline blends.

Electroplating

All platinum group metals can be electroplated. Because of the hardness and brilliance of the resulting coating, rhodium is most commonly used. Although itthe cost is higher than platinum, the lower density allows the use of a smaller mass of material with a comparable thickness.

Palladium is the platinum group metal that is the easiest to use for coating applications. Due to this, the strength of the material is significantly increased. Ruthenium has found use in low pressure friction machining tools.

Chemical compounds

Organic platinum group metal complexes, such as alkylplatinum complexes, are used as catalysts in the polymerization of olefins, the production of polypropylene and polyethylene, and the oxidation of ethylene to acetaldehyde.

Platinum s alts are increasingly being used in cancer chemotherapy. For example, they are part of drugs such as Carboplatin and Cisplatin. Ruthenium oxide coated electrodes are used in the production of chlorine and sodium chlorate. Rhodium sulfate and phosphate are used in rhodium plating baths.

Recommended:

Ferrous metals: deposits, storage. Metallurgy of ferrous metals

Metals are materials that never lose their relevance. They are widely used in household and industry

Precious metals quotes at Sberbank. Precious metals (Sberbank): prices

One of the most profitable investments is the purchase of precious metals such as gold, silver, platinum, palladium. This has been the case for many years and remains so today. In times of economic crisis, this option is even more relevant

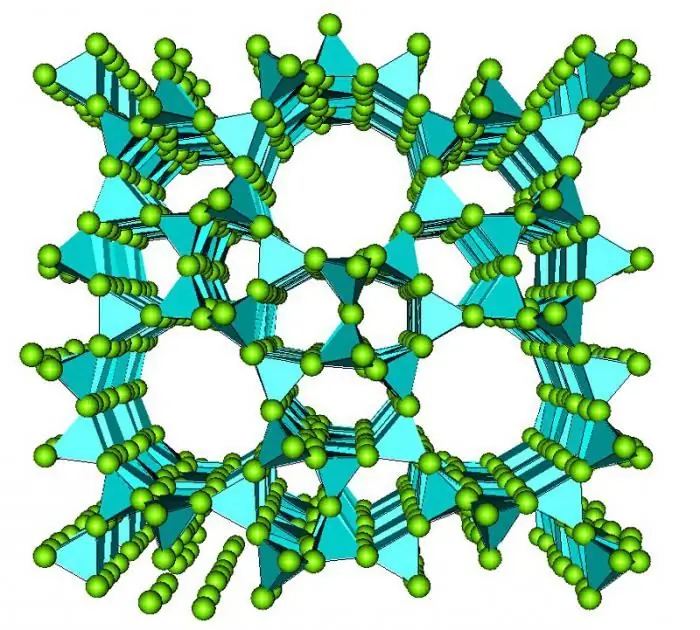

Zeolite - what is it? Zeolite natural and synthetic. Zeolite: properties, applications, benefits and harms

Its name translates as "boiling stone". It is impossible to count the uses of this seemingly simple mineral. It can even be eaten and used as a sieve for molecules. Such a versatile and useful zeolite

Aluminum alloys: properties and processing of metals

Aluminum alloys are very often used in construction, industry and other manufacturing industries. However, before using them, it is necessary to learn about the properties of alloys, as well as about the features of their processing

List of heavy metals: types and features

Of all the 104 chemical elements known to mankind today, 82 are metals. Metals occupy a prominent place in people's lives, playing both industrial, biological and environmental roles. Modern science divides metals into heavy, light and noble. In this article, we will look at the list of heavy metals and their features