2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:47

An asynchronous single-phase motor is a machine that converts electrical energy into mechanical energy, taken as a torque on its shaft. It got its name because with an increase in the load on the shaft, its speed decreases, lagging behind the frequency of rotation of the magnetic field. The difference between these speeds is called slip.

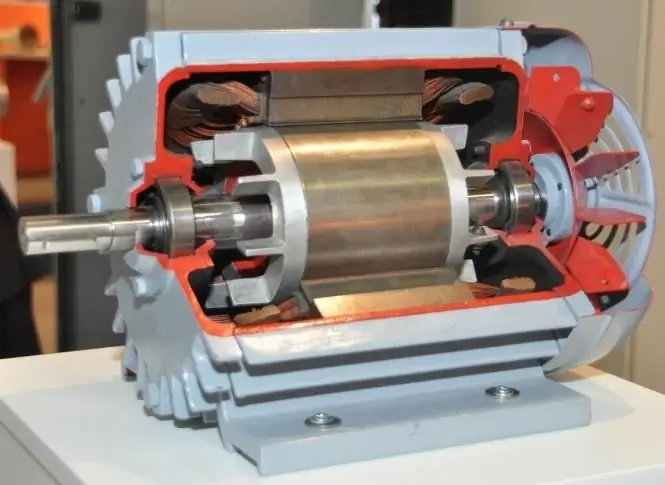

An asynchronous single-phase motor, like all electrical machines, consists of two main parts - a stator and a rotor. Inside the terminal box, fixed to the housing, conclusions are made, designated in different ways. There are four of them, and in order to connect them correctly, you need to understand the purpose of each of the two pairs of wires.

The asynchronous single-phase motor differs from a conventional three-phase electric motor in the number of windings and their configuration. There are two of them, and they are not the same. The main winding is designed to create a rotating magnetic field in an elliptical shape.

Right anglein relation to it there is an additional or auxiliary inductor that generates the starting torque necessary to give the rotor an initial rotation. The need for this element is due to the fact that one electrical winding excites a magnetic field, the symmetry axis of which remains stationary, and, therefore, additional force is required to move the rotor from its place. Its shape is elliptical, and it can be represented as the sum of two circular fields with opposite directions, one of which promotes rotation, and the other prevents it. The characteristics of such a machine for this reason are much worse than those of a three-phase one, however, in an apartment or house, you have to put up with this drawback.

In general, asynchronous single-phase motor is a low power machine, most often used for household electrical appliances. An example would be a hair dryer, vacuum cleaner, coffee grinder or food processor. Electric motors of this type do their job quite well, especially since there are practically no alternatives to them.

Connecting a single-phase asynchronous motor has its own characteristics, due to the specifics of the design. The fact is that the starting winding is not designed for long-term operation. The machine is started in short-term mode. After gaining the operating angular velocity, the circuit for excitation of the additional field must be open, otherwise it will be dangerously overheated and, possibly, out of order. Start-up time, as a rule, does not exceed three to five seconds. Openingcan be done either manually (just release the "Start" button) or automatically (using a timer opening relay). The most advanced devices use centrifugal systems designed to turn off the accelerating winding at the moment when the asynchronous single-phase motor reaches the rated speed.

Besides the additional winding and the start button, there is one more element necessary to make a single-phase asynchronous motor rotate. The connection scheme provides for a series connection with the inductance of the circuit, providing a phase shift. As a rule, this is a capacitor, when passing through which the electric current vector changes direction relative to the voltage vector.

Recommended:

Planning and economic department: its functions and tasks. Regulations on the planning and economic department

Planning and economic departments (hereinafter PEO) are created for the effective organization of the economy of organizations and enterprises. Although often the work of such departments is not clearly regulated. How should they be organized, what structure should they have and what functions should they perform?

Single-pole machine: device, specifications and connection features

In order to choose the right single-pole machine without errors, you should understand the markings printed on the case on the front side. The characteristics of the device are selected depending on the type of connected load and the cross section of the wiring

Hydrodistributor R-80: diagram, device, connection, do-it-yourself repair

The R-80 hydraulic distributor is used on tractors manufactured by MTZ, designed to redistribute the circulating fluid of these units. The mixture flows from the pump into the working space of the cylinder. The design of the device makes it possible to adjust the oil pressure in the system, fix attachments in the required position

Vertical milling machine, its device and purpose

To date, it is quite typical to use parts of complex configuration in various branches of mechanical engineering - shaping surfaces of stamps, molds, gears, copiers and many others. The main methods for manufacturing such complex-shaped products are the following: casting, stamping and cutting

How asynchronous machines work and who invented them

Asynchronous electric machines got their name because their angular velocity depends on the magnitude of the mechanical load on the shaft. Moreover, the higher the resistance to torque, the naturally it spins more slowly