2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:36

The R-80 hydraulic distributor is used on tractors manufactured by MTZ, designed to redistribute the circulating fluid of these units. The mixture flows from the pump into the working space of the cylinder. The design of the device makes it possible to adjust the oil pressure in the system, fix attachments in the required position. In fact, with the help of the node, the working equipment of the equipment is controlled.

Device

The P-80 hydraulic distributor is equipped with a body, a spring mechanism, an upper and lower cover, a fixing element, channels for the passage of liquid, several types of valves, an adjusting screw, spools, a booster and a retainer clip. The knot is controlled by levers with spherical bearings.

Spools

Spools are rollers in the form of cylinders, subjected to careful processing. In specifically defined places, there are provided grooved nests. They areare placed in suitable and prepared places on the hull. During installation, the spools pass through special channels and cavities towards the axes. As a result, the spool elements slightly open some channels, closing other working openings. This design contributes to changing the direction of fluid flow. The spools are driven by a lever that operates in four positions:

- Neutral.

- Work on the rise.

- Free swimming.

- Forced lowering.

The indicated positions of the P-80 hydraulic distributor have a certain fixation. Holding the lever by hand is provided only in the "forced lowering" position. Spool attachments are equipped with an automatic return to neutral position from fixed modes.

Operation principle

The P-80 hydraulic valve arrangement allows the spools in the neutral position to remain under the force of the springs. They block the injection compartment from the working grooves, while the liquid does not get to the cylinders. In addition, the oil path to the drain holes is cut off. The piston in this situation remains in a strictly fixed position. After the start of the oil supply through the pump into the discharge cavity, the lower part of the bypass valve is actuated. Under this directional force, the element opens, the oily liquid is transported to the bottom of the P-80 hydraulic valve and flows to the drain channels.

The control groove remains ajar, while some of the oildrains without preventing the bypass valve from opening. If the spool is in the floating position, both compartments communicate with each other via a drain line. The working fluid from the pump flows freely through the distributor and enters the tank through channels that are activated in the neutral position. In this mode, the piston is able to move under the influence of the rod load, due to the aggregation of both cylinders.

Features

The R-80 hydraulic distributor, the diagram of which is shown below, working on lifting or forced lowering, communicates one working cavity with the drain system, and the second analogue - with the discharge element. The control channel is blocked by the spool belt, the oil pressure in both parts of the bypass valve piston is equalized. In this case, the valve of the redistributing mechanism goes down under the influence of its own spring. The flow of oil to the drain is completed.

Under the influence of the liquid, the piston in the cylinder moves, bringing the equipment and working elements of the machinery into operation. The automatic return of the spools from the "lift" mode is due to the pressure generated. Its value is identical to that observed when the safety valve is activated. It connects to the drain line, after which the pressure parameters drop slightly. In the opposite channel, it remains consistently high as the bypass valve is in the closed position.

Due to the pressure difference in the channels of the node, an opening is observedholes, after which the oil fluid begins to flow under the booster. The spool no longer locks into place, springing back to neutral. In the forced lowering position, the working channel is connected to the waste compartment. The pressure indicator at which the fixation of the spool stops is only 2 MPa.

Connection

Connection of the P-80 hydraulic distributor to pipelines or hoses is carried out exclusively through fittings, flanges and other intermediate elements. The working fluid in the system must have a purity of at least category 16 in accordance with GOST 17216. Oil is cleaned using a fine filter (25 microns).

Spool controllers that are not involved in servicing the tractor equipment should preferably be set to the neutral position. During maintenance and preventive inspection, it is recommended to adjust the pressure of the safety valve to the values specified in the machine manual. The data is checked using a pressure gauge connected to the pressure head of the distributor. Correction is performed at the maximum crankshaft speed, taking into account the calculated pressure value.

Outlet pressure should not exceed 0.5 MPa, and the distributor placement level should not be lower than that of the top point of the oil reservoir. The considered devices with any kind of spools are used in the hydraulic systems of tractors and agricultural machinery.

Repair of hydraulic distributor P-80

Repair of the part in question requires some knowledge of hydraulics. Otherwise, an inept recovery process can only make matters worse.

Having studied the structure of one hydraulic distributor of the system, you can easily deal with similar drives of similar designs. All of them have an almost identical structure with a similar principle of operation, including modifications with several levers or controlled by a joystick. During diagnostics and repair, special attention is paid to the spool, valves and housing.

Frequent faults

A rather serious problem with the distributor is the development in the seating slots between the body and the spool. You can detect such a defect by touch. Its appearance is evidenced by longitudinal scratches and scuffs, vibration of the spool. It should be noted that the spool elements are not interchangeable. Some craftsmen, when repairing the R-80 hydraulic distributor with their own hands, adjust the spool from another distributor in size. This makes it possible to extend the life of the part. Experts do not recommend this approach, despite the fact that professional restoration of seat gaps is a very laborious and expensive process.

The main reasons for unauthorized lowering of working equipment (bucket or boom) are the lack of tightness in rubber seals or clogging (wear) of the valve needle. If such a problem occurs, the diagnosis should begin with the valve.

Checking the entire system

In case the malfunction is related only to attachments, the reason may lie in additional valves, cylinders. Check the elements by switching off one by one. If the working system refuses to work completely, you should increase the pressure value in the valve, check the needle, pump, plug, the presence of foreign objects in the pipelines and the distributor of the system.

Recommended:

Aircraft device for dummies. Aircraft device diagram

Few people know how an airplane works. Most don't care at all. The main thing is that it flies, and the principle of the device is of little interest. But there are people who cannot understand how such a huge iron machine rises into the air and rushes at great speed. Let's try to figure it out

Single-pole machine: device, specifications and connection features

In order to choose the right single-pole machine without errors, you should understand the markings printed on the case on the front side. The characteristics of the device are selected depending on the type of connected load and the cross section of the wiring

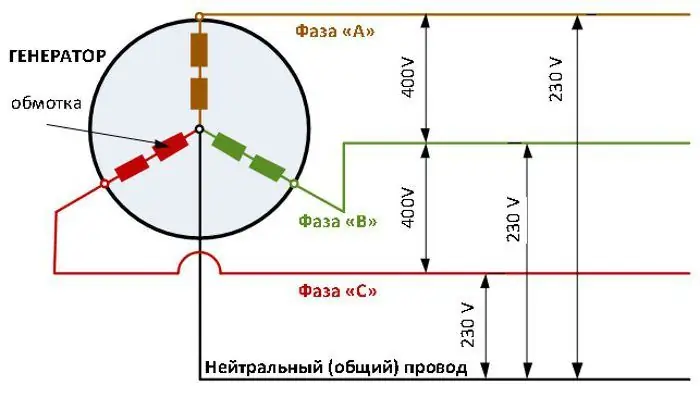

Three-phase network: power calculation, connection diagram

When properly designed and maintained, a three-phase network is ideal for a private home. It allows you to evenly distribute the load across the phases and connect additional power consumers, if the wiring section allows

Asynchronous single-phase motor, its device and connection

Connecting a single-phase asynchronous motor has its own characteristics, due to the specifics of the design. The fact is that the starting winding is not designed for long-term operation. The machine is started in short-term mode

Golovnaya Zaramagskaya HPP: height above sea level, photo, location, connection diagram

North Ossetia is rich in wild mountain rivers. These rivers have enormous potential in hydropower. In 2009, the head Zaramagskaya HPP was launched. The river on which the hydroelectric power station is located is called Ardon