2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:47

The reason why asynchronous machines are widely used is the simplicity of their design, reliability and manufacturability. Applicability for a three-phase and single-phase network, a wide power range, ease of changing the direction of rotation - all this makes them indispensable as drives for a wide variety of devices, including machine tools and conveying systems.

The essential advantage that asynchronous machines have is their high efficiency.

The most common electric motors are kilowatt, their use is very wide, in almost every industrial enterprise they make up the majority of drive devices.

Asynchronous electric machines got their name because their angular velocity depends on the magnitude of the mechanical load on the shaft. Moreover, the higher the resistance to torque, the naturally it spins more slowly. The lag of the angular velocity of the rotor from the frequency of rotation of the magnetic field created by the current passing through the stator windings is called slip. It is calculated, as a rule, as a relative value:

S=(ωn-ωp)/ ωn

Where:

ωn - magnetic field rotation speed, rpm;

ωp - rotor speed, rpm.

The dependence of the relative amount of slip on the load on the shaft is manifested in particular in the fact that in the idle mode S is practically equal to zero.

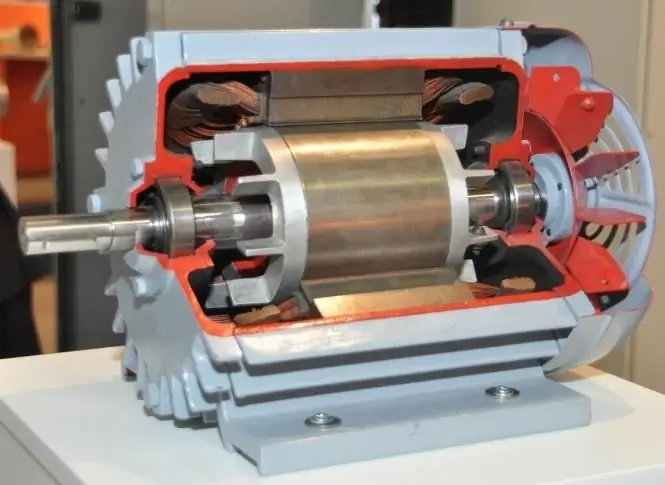

The device of an asynchronous machine is the same as any other electric motor or generator. The inner surface of the stator is equipped with special grooves into which the windings are laid (in the case of a three-phase power supply, there are three of them, and for single-phase motors - two). The rotor is also simple, with a squirrel-cage design, and the windings are short-circuited or have slip rings.

In the case of a squirrel-cage rotor due to inductive pickup from the stator currents, an EMF occurs in the rotor windings according to the right hand rule. Further, everything is simple: two frames through which an electric current passes begin to interact with each other, and a torque appears.

Asynchronous machines, the rotor of which is equipped with slip rings, work even easier: the power to the rotating windings is supplied directly through the graphite brushes. Such rotors are also called phase rotors.

Single-phase asynchronous motors have two windings, working and starting, designed to create an initial torque and spin the rotor to a working angularspeed. These motors are used where a three-phase network is not available, for example, to drive the rotating parts of household appliances.

In addition to motors, machines with opposite purposes, generators, are asynchronous. Their device is almost the same. To the credit of Russian electrical engineering, we can confidently speak about the priority of our country in the field of electric motors of this type. M. O. Dolivo-Dobrovolsky back in 1889 was the first in the world to use a three-phase power supply and obtain a rotating magnetic field. Modern asynchronous machines are fundamentally no different from the first three-phase electric motors of the great Russian inventor and scientist.

Recommended:

Semiautomatic welding machines: rating, pros and cons of the best machines

We present to your attention the rating of the best semi-automatic welding machines. The list includes the most popular and most intelligent models that can be found on the domestic market. Consider the remarkable characteristics of the devices, as well as their pros and cons

Work permit for work in electrical installations. Rules for work in electrical installations. Work permit

From August 2014, Law No. 328n comes into force. In accordance with it, a new edition of the "Rules on labor protection during the operation of electrical installations" is being introduced

A related profession is The concept, definition, classification of work performed, the performance of labor and related work and payment rules

What are related professions? How are they different from combining and retraining? What professions are related? Consider the example of a teacher and a pharmacist, an accountant and a lawyer. Working related professions. Three ways to master them. Motivation - leadership attitude

Review and rating of industrial washing machines. What are industrial washing machines for laundries

Professional washing machines differ from household models in that in most cases they have higher productivity and other modes, as well as work cycles. Of course, it should be noted that even with the same technical parameters, an industrial model will cost several times more. A little later you will understand why this is so

Who invented the dollar: history, stages and evolution

The dollar is almost the most popular and desired currency in the world. Recently, the market has been gradually flooded with the euro, which claims to world domination. However, the old "green" dollar is not losing ground yet. Perhaps the one who invented the dollar did not count on such a stunning reputation for his offspring