2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:36

Riveted joints are made from special parts. Such a fixed bond is difficult to separate. Rivets themselves are made of plastic material.

Building

Riveted connections consist of three elements:

- two parts to be connected;

- rivet.

The last element is placed in special holes, which are located on the edges of the parts to be joined.

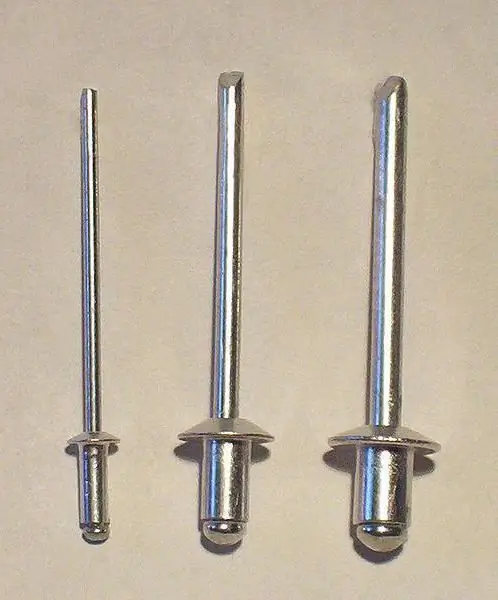

The rivet holds the part in the required position. In this case, the fixing element has the following structure:

- body;

- rod;

- mortgage head - serves to form the future product;

- closing head - formed in the process of connecting two elements.

A huge number of rivets are used to fasten large parts. In this case, the finished joint will be called a rivet joint.

Application areas

Before the advent of high-quality welding, riveting of parts was widespread. It is currently used in some areas of technology. Riveted connections of parts are used in the construction of aircraft, ships, submarines, as well as for various high-precision instruments. In addition, rivets are used when connecting building elements, such as an I-beam, a channel, a corner.

They help withstand variable vibration loads. Rivet joints are used to combine different types of material. For example, for bonding iron alloy products to aluminum sheet.

Riveted connections. Advantages and disadvantages of the bonding method

Among the positive aspects are:

- simple technological design;

- ability to join dissimilar metals;

- high connection reliability;

- resists vibration and shock loads.

However, like every connection, it has its negative sides, among which the following stand out:

- to create a rivet fastening, you need to spend a large amount of metal;

- requires significant labor costs;

- high cost;

- riveted joints can break due to the wrong diameter of the holes that are on the edges of the products;

- during operation, the tightness of the connection decreases.

Types of rivet jointsquite a lot, since each of them is used in a specific industry.

Riveted connections: classification

This type of connection is divided according to the following principle:

1. Functional purpose. Among the connections, there are three main types: strong ones are used to hold large loads; dense, which provide tightness; combined - perform both functions.

2. Technological design of the seam. The connecting seam can be overlapped and butted.

The last look is performed using one or more overlays.

3. Number of slices. This indicator shows the number of sections passing through one rivet under the action of a load. According to this principle, rivet joints are single- and multi-shear. Their number is not limited.

4. Number of rivet rows. There can be one, two, three, etc. The number is not limited.

As mentioned earlier, rivet joints are used in a variety of industries. Therefore, there are different types of rivets. In addition to the above indicators, these types are classified according to the shape of the embedded heads:

- semicircular;

- secret;

- semi-hidden;

- cylindrical.

Rod

The following types are distinguished by its shape:

- solid;

- hollow (have a through hole);

- semi-hollow - the rod is divided into two parts: one is solid and the other is hollow.

Basicinformation about fasteners and components is contained in the regulatory documentation.

GOST 10303-68 characterizing riveted joints includes the main standard sizes of a rivet. Its diameter, the length of the body and the rod, as well as the type of head are registered here.

Material of production

The main materials for the manufacture of rivet joints are low-carbon steels, non-ferrous metals, and some alloys. Despite this, there are strict requirements for each material:

- To facilitate installation of the product, the material must be plastic.

- Materials must have the same expansion temperature. If this requirement is not met, additional voltage will occur during temperature changes. Eventually the rivet joints will fail.

- Materials must be homogeneous. This is done so that the galvanic current does not destroy the connections. For example, steel rivets are used to fasten steel parts, copper elements are used to fasten copper elements, etc.

Loads

The allowable ones have been determined as a result of numerous trials and experiments. In addition, they have been carefully studied by specialists.

There are several types of loads: shear stress, tension and shear stress. For each type of metal, these indicators differ from each other.

When using two mild steel members, allowablethe tensile load should not exceed 150 MPa, and the shear stress should not exceed 100 MPa.

It is worth noting that these indicators were developed not only for connecting elements, but also for rivets.

They have their own allowable loads. For example, for carbon steel products, the shear stress should not exceed 100 MPa. For collapse, it is no more than 300 MPa.

Permissible loads for elements depend on the method of making holes in products.

If there is a lot of stress, holes should be made by drilling.

In case of temporary impact on the product, the allowable loads are reduced by 20%. In some cases, such as cold riveting, this figure is reduced by 30%.

Recommendations for the production of rivet joints

These connection manufacturing rules have been developed by highly qualified specialists. They were identified as a result of many years of testing in the laboratory, as well as during the operation of the connection. So, among them are:

1. Fasteners and rivets must be made of a strong homogeneous material.

2. Rivets should provide a small amount of loosening between parts. For this, as a rule, I use the chess method of fixing.

3. The occurrence of bending of the main structural elements should be avoided. To do this, the rivets are placed along the axis thatpasses through the center of connected elements.

4. Elements that have different diameters cannot be used on one rivet joint.

5. To avoid rotation of the parts to be joined, the number of rivets must be at least two.

6. The number of elements on one side should not exceed three. With an increase in this indicator, the strength of the product will decrease.

7. A butt joint requires more rivets than a lap joint.

8. It is necessary to ensure tightness. To do this, special glue or paint is applied at the rivet points, which are obtained using flame spraying.

9. After fixing the parts, they check.

10. The number of rivets depends on the design of the rivet connection.

Such a connection is not very common nowadays. It was almost completely replaced by welding.

However, it is used in the manufacture of aircraft, ships, and some instruments. The main advantages are the high strength of the finished joint and easy installation. However, to use it, you need to spend a significant amount of metal. Therefore, this type of connection is expensive and labor intensive.

Conclusion

There are a large number of rivet joints.

The main types and standard sizes of rivets are specified in the normative documentation. The type of element depends onindustry used. Installing them requires precise execution. The slightest deviation in the diameter of the hole can lead to the destruction of the entire product.

When making them, it is necessary to adhere to some rules that were compiled by experts on the basis of many years of calculations and experiments.

So, we have considered the features of this type of connection.

Recommended:

Leasing: advantages and disadvantages, main function, classification, tips and tricks

Definition, functions, advantages and disadvantages of leasing as a form of financial activity. General information, classification of leasing relations. Pros and cons of buying a car on lease, as the most common product. Recommendations for choosing a leasing company

Business connections: defining the concept, reputation, connections, establishing relationships

Success in business is impossible without establishing relationships with other people. Therefore, every business person tries to expand his circle of contacts, because any business or friendly relationship can become a necessary resource in business development. Let's talk about what connections and relationships are in the business world, how to develop connections, and why they are needed

Detachable connections: photo, drawing, examples, installation. Types of detachable and permanent connections

In mechanical engineering and instrumentation, not only the parts that are used in production, but also their connections play a very important role. It would seem that everything should be extremely simple, but in fact, if you delve into this topic, you will find that there are a huge number of different compounds, each of which has its own advantages and disadvantages

What are flange connections? Types of flange connections. Flanged connections in industry

Flanged connections are often used in industry. They must ensure the tightness and strength of the assembled structures. The role of a high-quality connection is important, because a weak bond can lead to large losses and threaten the danger to the operating personnel

Connections: purpose, types of connections. Examples, advantages, disadvantages of types of compounds

Machines and machine tools, equipment and household appliances - all these mechanisms have many details in their design. Their high-quality connection is a guarantee of reliability and safety during work. What types of connections are there? Let's take a closer look at their characteristics, advantages and disadvantages