2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

Rubber tiles, which can be produced independently, must be made according to a certain technology. This material appeared on the building goods market relatively recently. However, it can be noted that although this production is not widespread, it has good prospects. In order to understand what materials to use, it is necessary to consider several characteristics. First of all, the warranty period of the rubber coating is limited to 20 years. The second thing you need to pay attention to is the anti-slip qualities of the coating, which greatly expands the area of use of such tiles. The third characteristic that buyers pay attention to is high elasticity, which prevents the formation of an ice crust in winter.

Rubber tile raw materials

Rubber tiles, which are produced quite often todaycarried out by private craftsmen, it contains crushed rubber, which acts as a result of the processing of car tires. The resulting material, including recycled tires, has all the qualities that paving slabs should have. Among them are increased resistance to wear, strength, elasticity and excellent ability to retain shape. The material is resistant to acid and alkaline environments. Rubber tiles, the production of which can be established independently, has an insignificant cost, despite the high performance. This is due to the fact that the material consists of recycled materials, namely rubber crumb, the cost of which is very affordable. You can buy 1 kg of this material for only 30 rubles. The cost of the crumb may be lower, it depends on the color, size, and processing technology of raw materials.

Production technology

If you are going to produce rubber tiles, there are two ways to produce this material: one involves the use of a hot method, while the second technology involves the use of cold pressing. The equipment for these two technologies is similar to each other. Hot pressing has not been widely used due to the fact that it has side effects. With the increase in production efficiency, the quality of tiles has noticeably deteriorated, wear-resistant qualities have decreased, and an unpleasant smell of finished products has also appeared. Using the cold method does not give such side effects. The production of tiles from crumb rubber implies the need for mixing raw materials at the first stage. Next, pressing takes place at normal ambient temperature. At the last stage, the material is dried in chambers for 6 hours.

Special equipment

If you will be producing rubber paving slabs, production can be established by purchasing a drying chamber, a mold and a volcanic press. You will need at least two mixers.

Technology Features

First, the crumb rubber and other components of the mixture must be loaded into the mixer. This technique has low-speed blades. As a rule, the solid components of the crumb and the glue are mixed separately, which necessitates the use of two pieces of equipment. The production of rubber tiles and paving stones involves the installation of a mold on the table. There is also a laying of the composition for the tiles. After the mold must be installed in the trolley and subjected to pressure. In the next step, the carts must be moved to the drying chamber. It maintains a low temperature within 60 degrees. However, high humidity is created. The technology for the production of rubber tiles provides for the need to ensure the conditions under which chemical reactions occur, they guarantee a sufficiently tight connection of the elements of crumbs, glue andpigments. The crumb in the course of this increases in volume, voids appear that are filled with a binder.

Productivity of the technological line will be determined by the dimensions of the drying chamber. If you want to go into production on a commercial basis, then for profitability you need to choose a minimum chamber volume, which is 200 square meters. Depending on these parameters, other equipment must be selected according to the type of molds and trolleys.

Market Watch

If you decide to purchase equipment for the production of rubber tiles, then first you need to probe the soil, which will make it possible to understand whether this production will be profitable. Thus, in the building materials market, paving slabs are currently offered for sale at a price that is equal to 1,500 rubles per 1 square meter. By selling it wholesale you will have to lower the cost, but by selling large quantities and continuous production, the profitability can be about 40 percent. It is important to know that the initial costs that went to the equipment will pay off within six months. If we are talking about a small enterprise, then this indicator is very good.

Recommendations for the production process

Before starting work and starting a business, you will have to purchase equipment for the production of rubber tiles. It is important to try to save at the first stage. If you use the cold methodpressing, then this task will be completed, since energy will be consumed in a not so impressive amount. However, the savings will not be too great, since in continuous production, a constant temperature must be maintained in the oven. But if hot pressing is preferred, the production line will cost four times as much as one that provides cold forming products. That is why it is important to determine which technology will be used.

Conclusion

If the business has picked up momentum after starting production and you feel the need to increase capacity, then you will only need to buy a mold or an additional press. It won't cost too much. It should be noted that the establishment of production for laying rubber tiles for their own needs is impractical. It will be cheaper to purchase finished products in the building materials market. The benefit will be noticeable only when you decide to make the production of tiles your business.

Recommended:

Harvester head: market overview and selection tips. Industrial equipment

The article is about harvester heads. The nuances of choosing this equipment, manufacturers, as well as prices are considered

Equipment for pasties: overview, specifications, production and reviews

People loved, love and will love fast food. Yes, against the backdrop of a general passion for a he althy lifestyle, such a statement sounds risky, but the fact remains: few people will remain indifferent to the opportunity to intercept something very tasty, fast and harmful on the run. Probably the very first representative of "fast food", originating from the Soviet era, is cheburek. Flowing with meat juice, crispy, piping hot and indescribably delicious… Wanted?

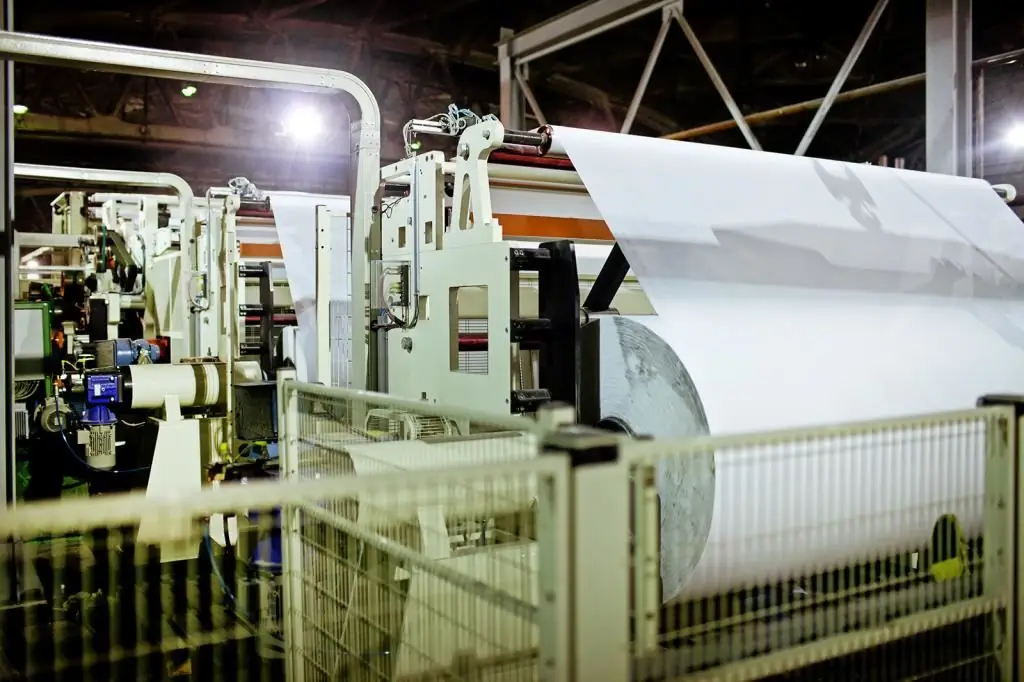

Pulp and paper mills in Russia: list, features of the production process, product overview

The pulp and paper industry of the Russian Federation is considered a complex industry. It is associated with the mechanical processing of wood and its subsequent chemical processing. The result of this work is the production of paper, cardboard, pulp, as well as other products from them

Krasnoyarsk synthetic rubber plant: production facilities, product overview

Krasnoyarsk Synthetic Rubber Plant has been producing products since 1947, deliveries are made to 35 countries of the world. The production is more than 42 thousand tons per year, the range includes 85 brands of rubber. The company is one of the ten world leaders in the industry

Choosing equipment for a summer cafe: the required minimum and a complete set

You can open a cafe for the summer season with minimal investment. Such a catering establishment, with the correct organization of work, will make good money. What equipment for a summer cafe will you need to purchase and how to choose the right format for the opening of the establishment?