2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:45

The pulp and paper industry of the Russian Federation is considered a complex industry. It is associated with the mechanical processing of wood and its subsequent chemical processing. The result of this work is the production of paper, cardboard, pulp, as well as other products from them.

Industry Features

The pulp and paper industry is distinguished by the following features:

- High material consumption - it takes about 5-6 cubic meters of wood (wood) to get one ton of pulp.

- Significant water capacity - it takes 350 cubic meters of water to make a ton of pulp.

- High energy intensity - it takes about 2000 kilowatt-hours of electricity per ton of products.

In view of the above, it follows that pulp and paper mills should be located near forest resources, not far from large water bodies, and this should be accompanied by the availability of the necessary energy capacities.

Territorial location of the pulp and paper mill

The Russian Federation, thanks to its hugeterritory, has very rich forest resources. This factor is a powerful stimulus for the development of the industry, which is able to meet the demand within the country in any volume and increase the volume of exports in significant quantities. Large pulp and paper mills in Russia are able to solve these problems in the shortest possible time.

A distinctive modern feature of the pulp and paper industry is the creation of timber processing complexes in its interests. This implies a combination of logging facilities with different production capacities in a certain area. Currently, the largest timber industry complexes in the Russian Federation are: Arkhangelsk, Syktyvkar (Northern Economic Region), Asinovsky, Ust-Ilimsky, Bratsk, Yenisei (Siberia), Amur (Far East).

Pulp and paper mills use complex and expensive equipment in their technological processes. The main goal is to produce products with the highest added value. The production index of the pulp and paper mill is considered one of the highest in comparison with other manufacturing industries. Paper mills are very important for the economic development of the Russian Federation. Especially for science, education and culture.

Products

Pulp and paper mills in Russia produce a range of various products. First of all, it is paper and cardboard. All kinds of stationery, sanitary products, household items.

Cellulose is actively used in the textile, food, chemical, perfumery, electrical and electronic industries. It is also indispensable in medicine, the military-industrial complex, and agriculture. Without it, it is difficult to imagine the aircraft industry, the production of cars.

Soluble cellulose is indispensable in the manufacture of viscose - the basis in the production of textiles. New applications include carbon fiber, biodegradable plastics, and nanocellulose.

Found widespread use of by-products of pulp and paper production. Ethyl alcohol, turpentine, furfural, tall oil, etc. are actively used in various industries, primarily in the oil and gas industry.

Production process

The process of making pulp at pulp and paper mills in Russia includes a number of steps.

Initially, the wood is sorted in the grinding shops. He is prayed, cleaned, chemicals are introduced (paint or special chemical fillers are introduced). Next, the resulting mass is sent to the cooking tanks (boilers).

To obtain pulp from this raw material, three cooking methods are used: sulfate, sulfite, neutral sulfite.

That cellulose, which was selected for further chemical processing, including for the manufacture of artificial fiber, is improved (it is treated with alkaline solutions). To give the desired color, bleaching is carried out.

Usually pulp andwood pulp is formed into bales for easy storage and transportation.

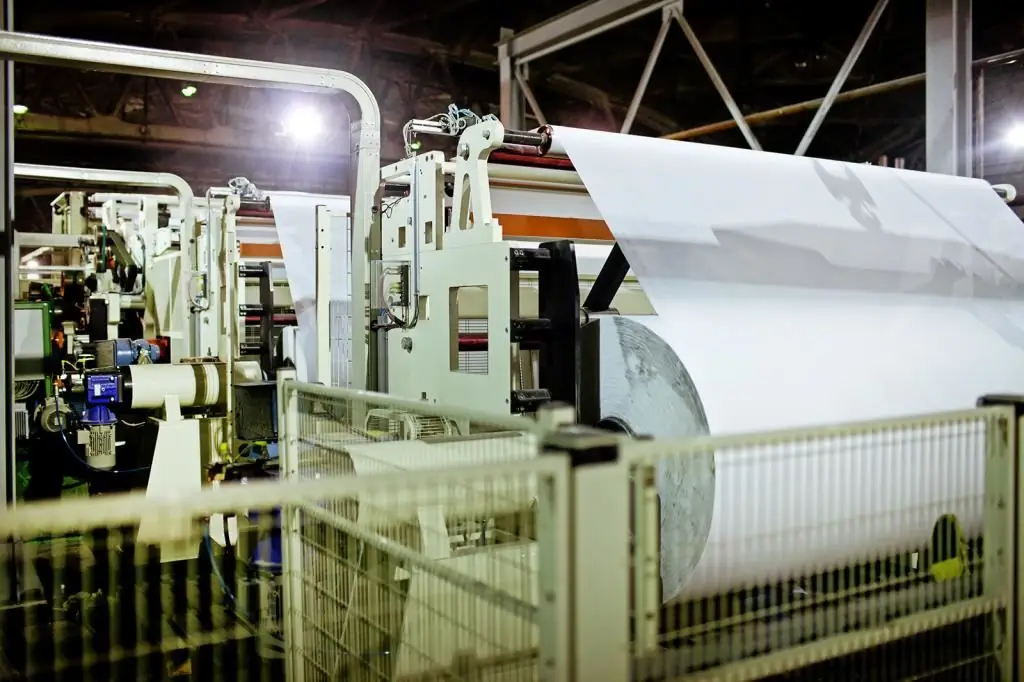

The next step is drying and pressing processing. Paper and cardboard are obtained as a result of repeated rolling and drying of the web in special devices. At the output, rolls of finished products are formed. Dimensions are pre-set by the programs of specific machines. Next, the rolls are cut using slitting machines and stored.

Pulp and paper structures

Currently, the list of pulp and paper mills in Russia includes about 150 enterprises. The largest of them are about thirty. They are located in the Perm Territory, the Republic of Karelia, the Republic of Mari El, the Republic of Komi, Arkhangelsk, Irkutsk, Nizhny Novgorod regions.

5 pulp and paper mills in Russia, which are leaders in production - pulp and paper mills in Koryazhma (Arkhangelsk region), pulp and paper mills in Bratsk and Ust-Ilimsk (Irkutsk region), Mondi SLPK (Komi Republic), Arkhangelsk pulp and paper mill.

It is worth noting that about 75% of pure (commercial) pulp is produced by the industry giant - Ilim JSC, which has many branches. These include the largest pulp and paper mill in Russia, located in Koryazhma.

Statistics

Russian pulp industry can rely on 809 million hectares of Russian forest reserves. Pulp and paper mills produce about 8.2 million tons of pulp and wood pulp per year. Of these, about 2.5million tons of commercial pulp. Pulp and paper mills also produce about 8.5 million tons of paper and cardboard. Statistics show that the Russian Federation is in 8th place in the world production of fibrous semi-finished products and in 13th place in the production of paper and cardboard. About 2.2 million tons of market pulp is exported. China is its main recipient.

Current challenges and favorable conditions

Export of Russian goods mainly consists of market pulp, newsprint, writing and printing paper, semi-finished products for the manufacture of cardboard containers and other packaging.

The composition of imports of paper products to Russia are goods that have a high added value. However, the volume of import deliveries to Russia has recently fallen significantly. This is facilitated by a number of factors, including the depreciation of the ruble, as well as a general decline in the use of cardboard and paper products in the country.

But pulp and paper industry experts say the drop in imports has a positive side. For example, many pulp and paper mills have begun to successfully implement import substitution programs. For example, the production of coated and lightly coated papers began, and an increase in the production of sanitary and hygienic products was recorded. It should be noted that the second direction is developing most successfully. First of all, this is the production of paper napkins, tablecloths, toilet paper.

Prospects

Prospects for pulp and paper mills in Russia are assessed by specialists as "having the potential for significant growth." According to their estimates, a serious increase in demand for pulp and paper products is expected in the next 10 years. It is estimated at about 500 million tons annually by 2030. The main consumers of pulp in the world will be China and Asian countries.

With this in mind, it is seen that pulp and paper mills located in the East Siberian region and the Far East, especially in those places where there is the necessary ratio of energy, water, forest resources, can seriously increase their participation in promising Asian markets. These prerequisites have already found understanding and are included in the Russian forestry development strategy until 2030.

Development plans, their practical implementation

Over the past decade, a number of pulp and paper mills in Russia have carried out serious work to upgrade equipment. Significant investment funds have been attracted. As a result, production increased, and the range of products produced also increased. New factories are being built. Thus, in the Trans-Baikal Territory, the construction of a pulp and paper mill is in the process of completion, which will produce about 400,000 tons of unbleached pulp.

Due to the fact that many enterprises carried out the modernization of production, pulp and paper mills in Russia have illiquid assets in large volumes, which are put up for sale.

Also carried outdevelopment of projects for the creation of a pulp and paper mill in the Vladimir (Alexandrov), Kostroma (Neya), Tyumen (Turtas), Chita (Amazar) regions. The list of paper mills in Russia is constantly updated, mainly upwards. Currently, work is underway to study the possibility of building new production facilities in the Novgorod, Kirov, Vologda regions, as well as in other regions of Russia.

Recommended:

Baikal Pulp and Paper Mill: echoes of unsustainable production

The unique Lake Baikal is also affected by environmental issues. One of them is related to the work of the Baikal Pulp and Paper Mill, located in the Slyudyansky district. The plant began operating in 1966 and was closed in 2013. What has been done to restore the ecological situation in the region. How are things today

Hammer mills: overview, features, instructions and reviews

One of the main agricultural operations is called grinding - grinding grains to the state of flour. The primary role in this process is played by crushers, among which hammer mills occupy a leading position

History of the creation of paper. Paper production

The article talks about how far paper has gone to reach its current prevalence. What was used before its appearance, what materials it was made of - all this is described in the presented material

List of new productions in Russia. Review of new productions in Russia. New production of polypropylene pipes in Russia

Today, when the Russian Federation was covered by a wave of sanctions, much attention is paid to import substitution. As a result, new production facilities are being opened in Russia in various directions and in different cities. What industries are the most demanded in our country today? We offer an overview of the latest discoveries

Citric acid production: preparation, process and product

Citric acid was discovered several hundred years ago, but the history of its full-fledged production at industrial facilities can only be spoken of since 1919. From that moment on, technologists began to apply microbiological processes, the development of which has not stopped to this day. At the same time, modern production of citric acid is heterogeneous and involves different ways of manufacturing the final product