2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:45

Crushing and grinding of raw materials are often required in various sectors of the national economy and industry. These can be food enterprises, and factories of heavy industry, grinding coal with semi-anthracite and all kinds of waste. In each case, the task is to provide technical support for this operation with a high level of productivity. Such requests are met by a medium-speed roller mill, which combines optimal power and design characteristics.

Unit device

With this equipment, you can perform a wide range of different tasks, in addition to direct grinding. This is the reason for the complexity of the design of some models. In the basic version, the standard roller mill, the photo of which is presented above,includes the following parts:

- Carrying platform with supporting elements. A metal structure on frames that supports the weight of the functional units. This part can contain both a stationary support and a running gear with wheels for moving.

- Power drive. Electric motor with gear and electrical infrastructure for connection to the mains (usually 3-phase 380 V sockets are used).

- Mechanical drive part. The force from the engine to the working parts is transmitted through a system of bearings, buffer springs, belt elements, gears, V-belts and a pulley.

- Working bodies. Directly rolls with teeth, carrying out grinding of raw materials.

The principle of the mill

The motor activates the movement of the rollers, which, depending on the configuration of the teeth, can perform crushing, coarse grinding and fine grinding. The gearbox drives the shaft and, in accordance with the specified mode of operation, rotation begins. Before that, the user loads the raw materials through a special funnel - it is integrated into the body through a detachable connection or is permanently present in the structure like the rest of the working components.

During operation, the output product may be separated into fractions. Additional organs of the roller mill are responsible for this. The principle of operation of the unit, for example, allows the processes of grinding, drying and separation to be carried out within one technological session. But in this caseit may be necessary to integrate auxiliary force transmitters and even drive mechanisms separately connected to power sources. Machines that perform heterogeneous operations from the effort of one electric motor, as a rule, have increased dimensions and a more complicated mechanical basis.

Types of roller mills

Distinguish between modular, disc and vertical designs of roller mills. The modular device is the most modern and allows you to perform the layout of the shaft levers, rolls and damping system in different configurations, changing the overall, molding and functional characteristics of the equipment.

Dish-roller mills (roller-disk) are produced especially for the chemical industry. They are based on a rotating plate-disk, lined with special plates. Through this platform, the crushed raw material is sent through the supply fitting. Then the product passes under the rollers, where it undergoes grinding and, due to centrifugal force, is dropped to the armored ring, where the separation process begins.

As for vertical mills, they are considered the least flexible in terms of the possibilities of the structural and assembly device, since they are calculated for a stationary permanent installation within a specific project without the possibility of change. But on its own, the vertical form factor, with top-down functional units (from the hopper to the lower crushers and separator), is the most productive.

Features of flour roller mills

The fundamental difference between flour grinding machines is a reduction in the size of the structure, an increase in the number of roller elements and an optimized system for classifying the product according to the quality of processing. Such machines, in particular, are produced by the German company Nagema, which represents an eight-roll flour mill. Description of laboratory modifications of equipment with the possibility of obtaining trial granular grinding of grain can be represented through the following structural composition:

- Multi-grain grinding elements.

- Receiving trays designed to collect and classify bran flour.

- Sieves through which flour of different quality is separated. Some systems also provide an estimate of grind through electronic sensors.

- Bran flour is sifted with a silk mesh with an aluminum overlay after wheat is crushed. By the way, silk nets can have different parameters with mesh sizes from 150 to 300 microns.

As you can see, flour rollers can not only perform mechanical processing operations, but also make a basic assessment of the quality of the manufactured product and, in accordance with this, ensure its separation.

Key Features

Due to the variety of structural devices, this equipment may have different technical and operational parameters. But still,focusing on the average power level of the units, the characteristics can be represented as follows:

- The power potential of the electric motor is from 1300 to 5500 kW.

- Roll diameter for industrial models is up to 1500 mm.

- The length of the rolls for industrial models is up to 2000 mm.

- Pressure exerted during crushing of rocks - up to 250 MPa.

- Tooth height for vertical roller mills - from 30 mm.

- The diameter of the plate for disk units is from 0.5 to 2 m on average.

- The rotation speed of the plate is about 3 m/s.

- Capacity - from 10 to 25 t/h.

Control system

Modern models of mills provide for electronic process control with automation elements. The operator can adjust the speed of the rolls, the rate of feed of raw materials into the feed mouth, the rotation parameters of the separator rotor, grinding characteristics, etc. In automatic mode, the air flow is adjusted with the grinding pressure. By setting the initial data, you can expect to obtain the desired particle size distribution at the product outlet without interfering with the workflow. Since roller mills operate at high power with connection to three-phase networks, they are also provided with protective devices without fail. They also work automatically in case of short circuits, motor overheating or large voltage fluctuations in the network.

Disadvantages of the unit

Practically all roller mechanisms have a common negativefactor of action, which is in close contact with raw materials. Mechanical action on the material is accompanied by sticking of crushed particles on the surface of the rolls. Since in some technological modes of processing it is supposed to moisten the working bodies, after the completion of the procedure, the surfaces are completely covered with the final product. There is also a relatively modest degree of grinding in roller mills, which forces designers to experiment with the same increase in the number of crushing units.

In general, this equipment is considered obsolete and does not meet the new requirements for the production of crushed materials. On the other hand, the simplicity of the design and the ability to maintain high productivity with the optimal dimensions of the unit still retains the demand for roller machines.

Wear surfaces

Actually, this is one of the main operational factors of the negative spectrum, which is determined by the intensity of the mechanical impact on the feed material. It is obvious that the roll segments are primarily subjected to wear, which periodically have to be changed. The problem is that the highest coefficients of friction are present in the processing of hard raw materials, which require the use of highly abrasive teeth. In such modes of operation, the shortcomings of medium-speed roller mills are manifested, the wear of which imposes considerable costs for maintenance items. On the other hand, roller manufacturers do not stand still, offering more and more high-quality abrasive segments for grinding,provided with high chromium cast iron overlays.

Conclusion

Currently, there are few direct competitors for grinding rollers that could offer the same set of technical and operational qualities. The main advantages of this technique come down to the simplicity of the technical organization of material processing and a simple scheme for integrating into the production processes of a wide range of enterprises.

At the same time, roller mills are inferior in market positions to less productive, but more ergonomic and functional roller-ring, vibratory and jet units. Factors such as the maintainability and energy efficiency of equipment are also playing an increasingly important role. The technological level of roll structures also does not allow us to take the lead in our niche in terms of these indicators.

Recommended:

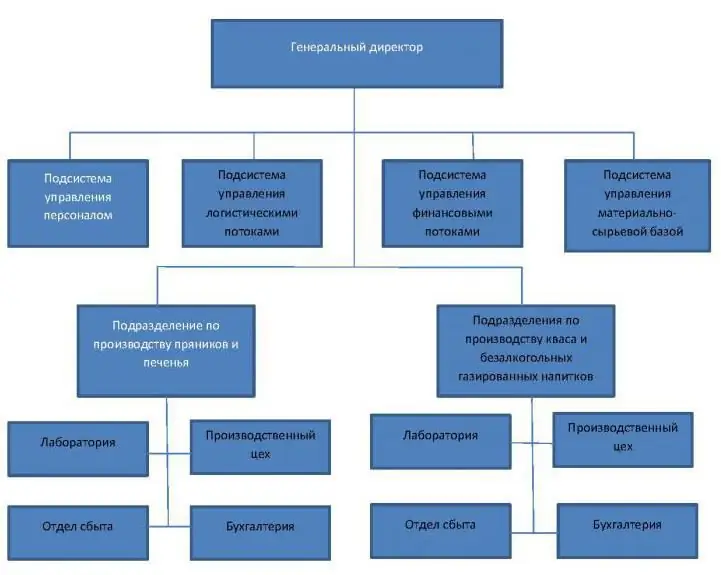

The organizational structure of an organization is Definition, description, characteristics, advantages and disadvantages

The article reveals the concept of the organizational structure of an enterprise: what it is, how and in what forms it is used in modern enterprises. The attached diagrams will help to visually illustrate the use of different types of organizational structures

Types of wear: classification and characteristics of wear

Wear is understood as the gradual destruction of the friction surfaces of various pairs. There are many types of wear. They are due to various reasons. But they all have one thing in common - the particles are separated from the base material. This leads to a disruption in the operation of the mechanisms, and in other cases can cause their breakdown. The gaps in the joints increase, the landings begin to beat as a result of the formation of a significant backlash

Wear. Types of wear and classification

What is wear and tear? Types of wear - how many are there? These questions are simple at first glance, but there are subtleties. This applies to both the very concept of "wear" and everything related to it

Galvanized roll: description, specifications and reviews. Chain-link mesh galvanized in a roll

Galvanized coil is a long steel sheet that is used for various purposes. Galvanized steel is produced in this form of any parameters and sizes. Specifications define performance and areas of use

Simmental, breed of cows: photo and description, characteristics, pros and cons of the breed

The Simmental cow breed is one of the most ancient. It is versatile, has both excellent meat and dairy characteristics. Simmental bulls gain weight very quickly. Their meat has a pleasant taste, so farmers often take them for fattening. Simmental cows produce excellent fat milk, which is perfect for making cheeses. They give birth to strong calves and have stable lactation