2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:38

Galvanized coil is a long steel sheet that is used for various purposes. Galvanized steel is produced in this form of any parameters and sizes. Specifications define performance and applications.

Description

The production process uses high-quality steel, which ensures that there is no damage, as well as flaws such as scuffs, swelling and bumps. The galvanized coil is covered with a protective polymer layer, which gives the tape not only certain physical and mechanical properties, but also shades. Thanks to this coating, the assortment increases to several dozen samples.

Specifications

The cold rolled method is used in the manufacturing process. Steel is prepared for rolls, the thickness of which varies from 0.25 to 3.75 mm. Depending on the dimensions of the roll, its width and steel thickness,the final product by weight can exceed 15 tons. Production standards are regulated by state standards 14918-80, after reading which, you can understand that the edges of the products should not have nicks and burrs, the surface should be uniform and even.

The width of a roll can reach 1250 mm, while the length is 3000 m. Galvanized steel coils are widely used in the automotive and construction industries, but this list cannot be called complete. Galvanized coil has many advantages, including resistance to corrosion and high temperatures. Such steel is used in the manufacture of profiled products, in the production of sandwich panels, household appliances and consumer goods. The inner diameter of the roll is 600 mm, and the coating can be single-sided or double-sided.

Galvanized steel coil reviews

Galvanized coil, according to buyers, can be produced by the method of hot or cold rolling. This process uses advanced technology, which greatly improves the quality of the final product and ensures high accuracy in thickness. This material is the most suitable for use in industrial production, which is due not only to chemical resistance.

Private consumers buy galvanized steel coils because it is:

- has a long service life;

- has low thermal conductivity;

- has an affordable price;

- high plasticity;

- characterized by ease of handling;

- has a compact roll size.

The material is not subject to wear due to the fact that it is treated with a special protective coating on one or both sides. Buyers note that the sheet is also resistant to aggressive environments. In the production of roofing materials, low thermal conductivity is especially valued, which also attracts the cost, which is important not only for manufacturing enterprises, but also for private buyers. According to consumers, the material has the ability to draw, and the edges can be easily changed by cutting or welding them.

In rolls, the material has a compact size, so it is easy to transport and store using trucks. This eliminates the possibility of mechanical damage and relieves the consumer of the need to search for special transport.

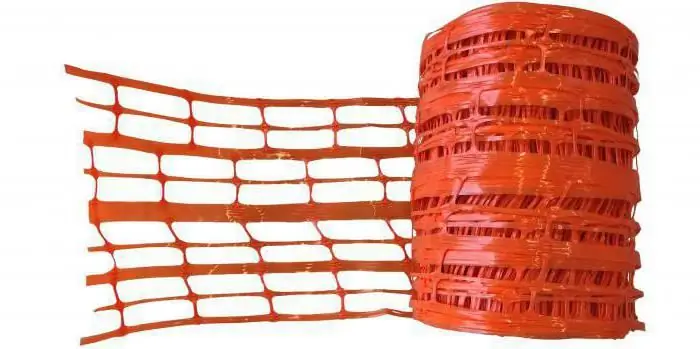

Description of the chain-link roll mesh

Zinc-coated wire mesh rolls are also on sale today. A protective coating is applied to its surface by fluidization. The material can replace the sectional fence, while the appearance of the mesh is more aesthetic. The protective properties of the material are higher compared to those possessed by a fence made of chain-link mesh sections. The material is durable, of high quality and processed during the production process by microcrystalline phosphating.

If the site is fenced like thismaterial, then the attacker will need more effort and time than, if necessary, to overcome the usual fence. Galvanized mesh in rolls suitable for fencing:

- sports fields;

- residential areas;

- industrial facilities;

- suburban areas.

The material is of high quality and reliability, maintenance-free, easy to install and high color fastness.

Specifications

You can also purchase galvanized welded mesh, the roll can have a different color, and the diameter of the wire used varies on average from 2 to 3 mm. Optionally, you can choose the size of the cell, which has a square or rectangular shape. In the first case, the side is 50 mm, in the second, the sides have the following dimensions: 50x100 mm. The weight of the roll varies from 6 to 73 kg, depending on the length of the web, as well as the diameter of the wire used.

Description of woven chain-link mesh

On sale you can find a chain-link mesh in a wicker form, which is a canvas of interlaced spirals. The size of the cells can vary from 6 x 6 to 55x55 mm. The wire diameter can be 1-2.8 mm. The weight per square meter varies from 0.7 to 3.5 kg. This material is used for the manufacture of fences and other needs.

Galvanized chain-link mesh, the price of which is 1716 rubles per roll, can have different sizes. In this casethe cost is indicated for a roll, the dimensions of which are 1x10 mm. The weight per square meter is 1.4 kg. The price will increase to 1852 rubles if the dimensions of the roll are as follows: 1.5x10 mm. The weight per square meter will be 1.6 kg. The price per square meter in this case is 123 rubles. The galvanized chain-link mesh, the price per roll of which is 1170 rubles, will have the following dimensions: 1.5x10 mm. The diameter of the wire used in this case will be 1.7 mm.

What else you need to know about galvanized chain-link mesh

The manufacturing method, which uses low-carbon steel, which has previously undergone a galvanizing process, as raw materials, is the most common today. It is preferred because the steel mesh netting receives the highest level of corrosion protection. Rolled metal is processed by the hot method, a layer of zinc is applied on top, the volume of which per square meter can vary from 70 to 90 kg.

Conclusion

Production is fully automated, so the mesh is formed by twisting the wire at a right angle. The galvanized mesh, the price per roll of which was mentioned above, will not have creases or gaps, and the end elements are bent to prevent injuries during installation and transportation.

Recommended:

Ochkarik chain of stores: reviews, features and assortment

Not all people can boast of excellent vision, because modern life is associated with a large number of irritating factors for the eyes. Opticians offer a wide range of glasses and lenses, among which you can choose the right option. In this article, we will talk about the Ochkarik chain of stores, analyze the main features and study customer reviews

Logistics and supply chain management: description, functions and features

Work as a logistics manager is called by many the profession of the 21st century. What is it connected with? Who is a logistician and what functions does he perform? This will be discussed further

H&M chain stores: reviews. H&M: reviews of employees, customers

H&M reviews are the first thing to look at before considering retail stores as a possible place to work for yourself. In this article, we will weigh the pros and cons of working in H&M

Afonya plumbing store chain in St. Petersburg: reviews, assortment and features

When it's time to change plumbing, everyone starts looking for the right store, where both inexpensive and high quality. Reviews about Afonya-spb.ru are varied, and before you bet on cooperation with this particular store, you should familiarize yourself with the advantages and disadvantages described by the buyers themselves

Protective mesh construction: description, application

Construction protective mesh has a high density of weaving. It reaches 35 g/m. This indicator is the minimum, while the maximum value is 200 g/m. In the conditions of construction sites, a mesh with a density of 75 g / m is usually used. This allows you to provide protective functions and prevents debris and building elements from falling