2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:26

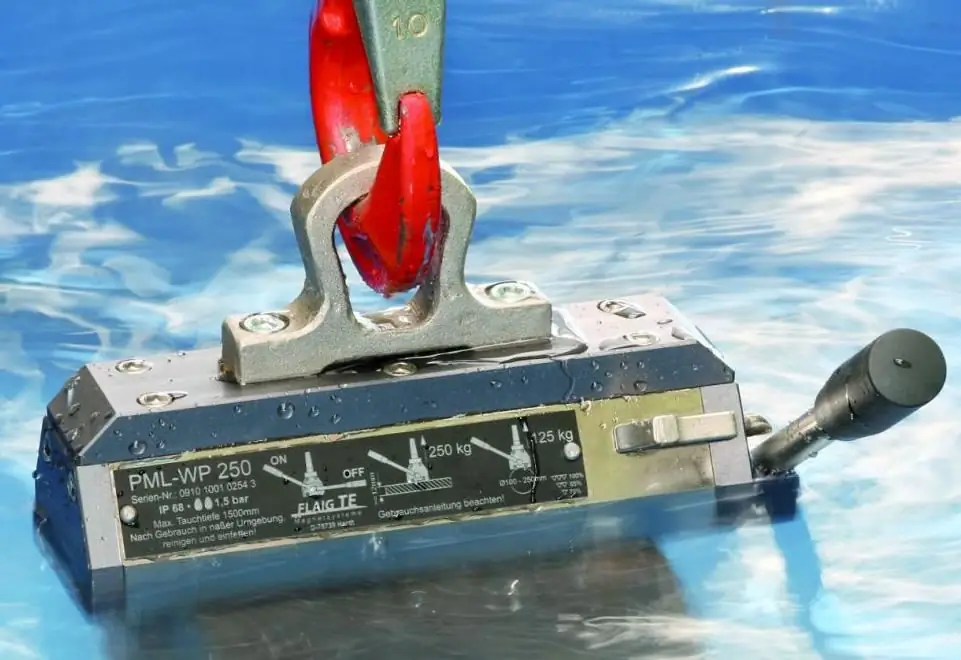

Magnetic gripper is designed for safe movement of loads made of ferromagnetic metals - steel sheets, round blanks, shaped pipes, cast iron beds and so on. The strength of the magnetic field lifts any parts, machines, mechanisms that have a flat or rounded surface. The scope of their application is great - from moving products around the shop to unloading vehicles. The advantage of such lifting devices is the acceleration of slinging processes, unlike traditional methods of transportation with hooks, chains, and other rigging. PML grippers securely fix the load, do not damage its surface, are compact, and almost do not depend on operating conditions.

Device, classification

Magnetic load handling devices are manual, impulse and automatic. The design of the magnetic gripper is universal. But different models have distinctive engineering developments of the manufacturer. The heart of any PML lifting device is a neodymium-iron alloy magnet with a rectangular shape enclosed in a metal case. Attached to the magnet is a replaceableoutsole with a flat or arcuate profile for pressing on surfaces of various shapes. The body has an earring or a hinged bracket for fastening on a lifting mechanism or a traverse, an eccentric axis driven manually or mechanically. The automatic loaders are equipped with special steel plates for degaussing.

Working principle

Unlike other metal grippers, the magnetic one works without slinging. With the help of the resulting magnetic field, the surface of the workpiece is attracted to the bottom of the PML gripper, firmly fixed. The larger the area of the pressed surface, the stronger the resulting field. Dropping of the transported parts is done by manually increasing the air gap between the part and the sole by turning the eccentric shaft. The automatic dropping method occurs by opening the individual parts of the neodymium magnets and the absence of tension on the straps that fasten the body to the hook of the lifting machine. In the latter case, leverage is used.

Advantages and disadvantages

Plus neodymium load grippers - saving time and energy for transporting goods, unloading them or feeding them to machines for further processing. These devices are universal, used for almost all types of alloys with ferromagnetic properties, carry out lifting of small and large tonnage loads in automatic or manual mode.

Working staff does not needadditional qualifications associated with the study of the device. Its structure is simple and operation is easy. The load gripper itself can be used in workshops, warehouses, boxes of any type without connecting to electricity, on manual hoists, truck cranes, crane beams. They are used in closed workshops, open warehouses, in any weather.

The disadvantages of magnetic load gripping include a decrease in the attractive force with an increase in the temperature of the part and an increase in size and design complexity with an increase in load capacity.

Selection Options

The main criterion for a load gripping device is its load capacity, but in the case of a magnetic grip, the list of requirements expands. In general, the load capacity of the device depends on the area of contact with the load and the chemical composition of the magnetic alloy. The first issue is solved in two ways - by choosing a large area magnet to increase the downforce or by purchasing several grippers of a lower carrying capacity, which are used simultaneously on the traverse. This is relevant when transporting sheet metal, when the edges gradually “peel off” from the sole of the gripper when the web is bent. Therefore, the choice of the rated power of the magnet depends on the shape of the load.

The thickness of the lifted metal and its temperature affect the parameters of the selected magnetic gripper. Since the properties of neodymium are lost when heated and with an increase in the distance from the center of gravity of the workpiece to the sole of the device.

When lifting loads, the allowable safety factor is taken into accountload capacity for different types of metal. PML type devices work with any surface roughness of the transported goods.

Recommended:

Movement of an employee: the order of movement, the nuances

Movement of an employee can be represented in several ways. The article describes when and how this procedure is performed. The main differences between the process and the translation are given, as well as the rules for processing the transfer

Classes of the Nice Classification: codes, list and classifier. What is the International Classification of Goods and Services?

For the registration of each mark of new products in business, the International Classification of Goods and Services is used. At the initial stage, the applicant determines under which category his activity falls. In the future, this will be the basis for the implementation of registration procedures and determining the amount of the fee paid by the entrepreneur

Electric locomotive 2ES6: history of creation, description with photo, main characteristics, principle of operation, features of operation and repair

Today, communication between different cities, passenger transportation, delivery of goods is carried out in a variety of ways. One of these ways was the railroad. Electric locomotive 2ES6 is one of the types of transport that is currently actively used

Low pressure heaters: definition, principle of operation, technical characteristics, classification, design, operation features, application in industry

Low pressure heaters (LPH) are currently used quite actively. There are two main types that are produced by different assembly plants. Naturally, they also differ in their performance characteristics

Gas piston power plant: the principle of operation. Operation and maintenance of gas piston power plants

Gas piston power plant is used as a main or backup source of energy. The device requires access to any type of combustible gas to operate. Many GPES models can additionally generate heat for heating and cold for ventilation systems, warehouses, industrial facilities