2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:26

Sand is a sedimentary rock and an artificial material that contains rock fractions. Quite often, it is made up of the mineral quartz, which is a substance called silica. If we are talking about natural sand, then it is a loose mixture, the grain fraction of which reaches 5 mm.

Classification by rock destruction

This material is formed by the destruction of rock solids. Depending on the accumulation conditions, the sands can be:

- alluvial;

- marine;

- deluvial;

- eolian;

- lake.

When a material is formed during the activity of reservoirs and streams, its elements will have a rounded rounded shape.

Main varieties of sand and features of their production

Today, almost all types of sand are used by man in various fields of activity and industry. River sand is a building mix thatextracted from riverbeds. This material has a fairly high degree of purification, which is why there are no small stones, clay content impurities and foreign inclusions in the structure.

Quarry sand is extracted by washing with water in a huge volume, as a result, it is possible to get rid of dust particles of clay. Considering the types of sand, you can find quarry sand, which is cleaned during the extraction process from large fractions of stones. This material is quite widespread in the manufacture of mortars that go to the laying of foundations and the implementation of plastering. You can also find seeded quarry sand in asph alt concrete mixes.

Construction sand must comply with GOST 8736-2014, according to which the material is a loose inorganic mixture of coarse grains, the size of which reaches 5 mm. The density of the material is 1300 kg/m3. Building sand is formed during the natural destruction of rocks, it is mined by the methods of developing sand-gravel and sand deposits without and using enrichment equipment.

The main types of sand also include artificial heavy sand, which has the appearance of a loose mixture obtained by mechanical crushing of rocks, among the latter should be highlighted:

- slag;

- granites;

- limestone;

- marble;

- pumice;

- tuff.

Features of artificial sand

They may have different origins and densities. If we compare the grains of a givensand with grains of natural origin, the former are distinguished by an acute-angled shape and a rough surface. Artificial sands are commonly used as aggregates in the preparation of plasters and decorative mortars. As a result, it is possible to achieve a tangible texture of the top layer on the outer surfaces.

This material can become a part of any layer of plaster, because the fractionation of the grains can be different, depending on the type of mortar. Usually the grain size is assumed to be equal to the size of natural sands. In the manufacture of artificial sand, burnt coal, rocks, as well as unburned particles, in which the sulfur content is low, are taken for processing.

The characteristics of the material will depend on the quality of the coating layer. In the manufacture of decorative plaster from such sand, crushed stone, powder of this rock or crumb can be additionally added to save money, it even benefits from this quality of the texture.

Application and characteristics of sea sand

Sea sand can be used in the production of building mixtures, the manufacture of aggregates, the implementation of plaster work, laying road bases, the construction of fences and barriers, as a filler for building grouts and dyes. The production of such sand is regulated by GOST 8736-93.

Fractions can vary from 2.5 to 3.5 Mk, which determines the particle size module. Grain density is equal to the limit of 2 to 2.8 g/cm3. The sea sand should be completely free of foreign matter.impurities, but in some fractions you can find a small content of clay and dust particles. Sea sand is characterized by the labor intensity of production, which makes its cost higher than quarry alluvial sand.

Characteristics and price of quarry sand

The main feature of quarry sand is the absence of impurities and frequency. Alluvial quarry material has the following characteristics: a fraction ranging from 1.5 to 5 mm, a density equal to 1.60 g/cm3, as well as a low content of clay, dust and other impurities. The latter in the composition should not be more than 0.03%.

Quarry sand, the price of which per cubic meter will be 2200 rubles, is used not only in construction, but also in decoration, as well as the national economy. Especially profitable is the use of such sand in the production of concrete and bricks, as well as in road and housing construction.

Quarry sand, the price for which will be 2300 rubles, can be presented in the form of a material with a fraction ranging from 2.5 to 2.7 mm. In the production of high-strength concrete and reinforced concrete structures, coarse quarry sand is usually used. Quarry material goes to masonry and paving slabs.

Technical characteristics of river alluvial sand and features of its production

Alluvial river sand has a density of 1.5 kg/m3. If we are talking about density in a state of natural moisture, then this figure will be reduced to 1.45.may contain dust particles, silt and clay elements, but not more than 0.7% by weight. The moisture content of the material is 4% while the specific gravity is 2.6g/cm3. These types of sand are mined using a dredger, which is fixed on a barge. Such equipment is supplemented with hydromechanical installations, powerful pumps, networks and tanks for dividing the material by composition. Extracting sand from dry riverbeds is like extracting quarry sand.

Conclusion

Almost all varieties of sand can be attributed to the first class of radioactivity. The only exceptions are crushed sands. If we talk about other varieties, then they are radiation safe and can be used in all construction work without restrictions.

The use of sand is quite common today. For example, its quartz variety is used for the manufacture of welding consumables for general and special purposes. As for the construction variety, it is used to obtain structural coatings by mixing with dyes. Sands are also used during finishing work, as well as in the repair of premises. The material also acts as a component of asph alt concrete mixes, which are used in laying roads and in construction.

Recommended:

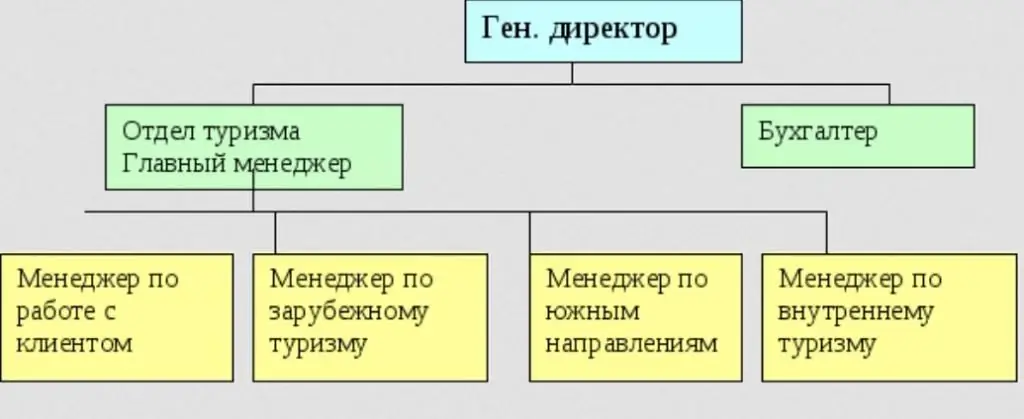

Types of tour operators and their characteristics. Functions and features of the activities of tour operators

The tour operator provides a wide range of travel services and simplifies the reservation of services in other cities and countries, taking on these tasks. In the field of tourism services, it occupies a special niche. In the article we will consider the types of activities of tour operators

Non-ferrous, precious and ferrous types of metals and their characteristics

Metals are a large group of simple elements with characteristic features such as high thermal and electrical conductivity, positive temperature coefficient and more. To properly classify and understand what's what, you need to deal with all the nuances. Let's try with you to consider such basic types of metals as ferrous, non-ferrous, precious, as well as alloys. This is quite an extensive and complex topic, but we will try to put everything on the shelves

Reserves of banks and their formation. Required bank reserves and their norm

Bank reserves ensure the availability of funds for the uninterrupted fulfillment of payment obligations regarding the return of deposits to depositors and settlements with other financial institutions. In other words, they act as a guarantee

Main types and types of business plans, their classification, structure and application in practice

Each business plan is unique, because it is developed for certain specific conditions. But you need to familiarize yourself with the features of various types of business plans in order to understand their key features. Experts recommend doing this before compiling your own similar document

Coal: classification, types, grades, characteristics, combustion features, extraction sites, application and importance for the economy

Coal is a very diverse and multifaceted compound. Due to its peculiarity of formation in the bowels of the earth, it can have very different characteristics. Therefore, it is customary to classify coal. How this happens is described in this article