2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:28

The modern global energy market is extremely volatile. It brings a huge amount of news and surprises. The most "surprise" part is, of course, new technologies. These include primarily the shale revolution and everything related to liquefied natural gas (LNG).

The technologies and processes of the LNG sector are closely watched by business and political communities around the world. Tectonic shifts in big world politics are sometimes due to the technological development of energy production and logistics.

LNG technology

Liquefied gas is obtained from natural gas using two physical processes: compression and cooling. In the final, liquefied gas is reduced in volume by six hundred times.

The technological process is multi-stage. Each stage is a compression of 5-10 times, followed by cooling and transfer to the next stage. When passing from the first to the penultimate stage, the gas remains a gas. It turns into a liquid only at the laststeps. To produce one ton of LNG gas, about one and a half thousand cubic meters of natural gas are required.

Technological stages with compression and cooling require significant energy costs, up to 25% of the total amount of liquefied gas.

Production nuances

LNG plants differ in the nature of the physical processes on which they operate:

- throttle;

- turbo-expander;

- turbine-vortex, etc.

Today, two processing methods are used in the world:

- Condensation or compression of gas against a background of constant pressure. This method is no longer among the effective ones due to high energy costs.

- Heat exchange methods using refrigerators or throttles based on changes in gas temperature.

One of the most important technological requirements for the production of LNG gas is the high quality of thermal insulation and heat exchange equipment.

If we talk about the process of production of liquefied gas as a whole, then it consists of four mandatory and sequential stages:

- Gas production from drilling rigs, pipeline delivery to the liquefaction plant.

- Gas liquefaction, LNG storage in special facilities.

- Shipment of LNG to tankers with transportation by water.

- LNG unloading at terminals, storage, regasification and delivery to the consumer.

LNG gas properties

The physical properties of liquefied gas are unique. He leadshimself very meekly: in its pure form, it does not burn and does not explode. If it is placed in an open space at normal temperature, the LNG will begin to evaporate quietly, mixing with air.

Ignition is possible, but only at a specific concentration of gas in the air: from 4.4 to 17%. If the LNG content in the air is below 4.4%, the amount of gas to ignite will be too small. If the concentration of gas in the air exceeds 17%, there will not be enough oxygen for the flame. This is the basis of the regasification process. Evaporation is simply done without oxygen, that is, without air.

LPG logistics

LNG delivery technologies are in no way inferior to the methods of its production in terms of their dynamism and advancement. If we conduct, for example, a rating of modern marine vessels in terms of aesthetics and design, then cruise liners will not win at all. Snow-white liquefied gas tankers will win, striking in their size, variety and unique designs.

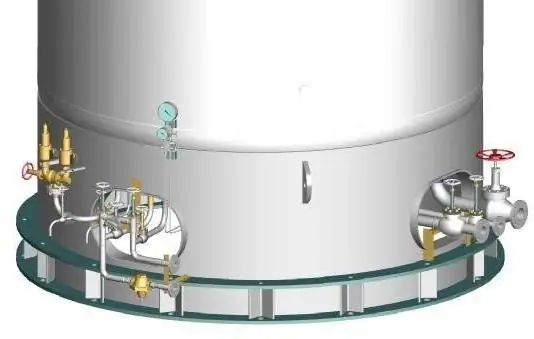

Liquefied natural gas plants are usually located close to where they are produced. At this stage, the most important element is the storage of LNG with the most serious technological requirements with their mandatory implementation. Cryo tanks are built on the principle of Dewar vessels, designed to store substances with a temperature that differs from normal. The main element in such vessels is double walls. Cryo-tanks for storage and transportation of LNG can be located on sea tankers or special vehicles. For rail transportation, special wagons are used in the formcryotank.

If LNG has already undergone regasification, it is sent to the consumer through a classic gas pipeline.

Which is better?

It has long been calculated that LNG transportation technologies are more profitable than a conventional pipeline over long distances exceeding several thousand kilometers.

In Russia, Gazprom is the most worried about LNG production. According to its leading experts, Russian LNG has already begun to be an unnecessary competition to the pipeline method. One of the arguments is the absence of an export duty and a tax on the extraction of minerals on the same Yamal LNG. This situation is called “loss of budget efficiency.”

It seems that President Vladimir Putin has found a compromise solution. He also does not see anything good in the competition between the two types of Russian natural gas. At the same time, LNG technologies need to be promoted in the domestic market of the country in order to rebuild public transport to a new type of fuel - natural gas. In addition to buses, there are many LNG consumers in Russia, mostly residents of remote areas where there are no gas pipelines and there will not be any.

Russian LNG

Sakhalin-2 and Yamal LNG are two operating gas liquefaction plants in Russia in 2018. The first and oldest enterprise is the Sakhalin plant, which is owned by Shell, Mitsubishi and Mitsui, and a controlling stake belongs to Gazprom.

Production of oil and associated gas, andLNG production also takes place under the terms of a special production sharing agreement. The LNG plant was put into operation in 2009, it became the first Russian enterprise of this profile.

The younger brother is the second plant owned by Novatek. This is the Yamal LNG project, which from the very beginning was focused on the export of liquefied gas. Within its framework, five loading terminals with a huge annual total capacity of up to 58 million tons will be built and put into operation.

US Gas

The US is not only the home of reduced gas technology, but also the largest producer of LNG from its own feedstock. Therefore, when the Donald Trump administration launched the ambitious Energy Plan - America First program to make the country the world's main energy power, this should be heeded by all players on the global gas platform.

This kind of political turn in the US was not much of a surprise. The US Republican position on hydrocarbons is clear and simple. This is cheap energy.

Forecasts for US LNG exports are very different. The biggest intrigue in trade "gas" decisions is developing in the EU countries. Before us is unfolding a picture of the strongest competition between Russian “classic” gas via Nord Stream 2 and American imported LNG. Many European countries, including France and Germany, see the current situation as an excellent opportunity to diversify gas sources in Europe.

As for the Asian market, the trade war between the US and China has led to a complete refusal of Chinese power engineers from imported American LNG. This move opens up huge opportunities for supplying Russian gas through pipelines to China for a long time and in huge volumes.

Safety when using LNG

Safety in many industries has become a boring routine. This attitude does not apply in any way to the production of liquefied gas, as well as to everything connected with the word "gas".

The main risks are associated with the overall flammability of the gas as a whole. The flammability of LNG is an order of magnitude lower, of course. LNG safety regulations focus on the spill and vaporization of LPG. If, for example, a new gas with a different density is poured into an LNG tanker (this happens), the liquids can separate without mixing. In this case, the denser gas will settle to the bottom with the formation of two cavities with independent circulation of liquids. Liquids are eventually mixed during convective exchange. If it occurs quickly, stratification begins: LNG evaporates quickly and abundantly. To prevent this, special devices for controlled mixing and special methods of filling tanks are used.

Advantages of LNG: Summary

Start with the benefits of using LNG in the domestic market. The use of liquefied gas in boiler houses is the most optimal type of fuel: the highest calorific value, maximum efficiency and a very moderate cost, which ultimatelyturns out to be even more economical than fuel oil.

LNG logistics is easily tied to boiler houses of any localization, including the most remote points, thanks to the well-developed production of LNG transportation means in the form of cryo-tanks of various configurations.

Because LNG burns more efficiently than coal or fuel oil, harmful emissions into the atmosphere are minimal: flue gases do not contain particulate matter or sulfur compounds.

From the point of view of LNG exports and the development of the global energy market, LNG and its production are becoming an increasingly priority factor for the world's largest economies, including France, South Korea, Spain, etc. The main global consumer of liquefied gas is Japan, whose gas imports are 100% LNG.

Recommended:

LNG tanker for the transport of liquefied gas

Reserves of natural gas in the world are huge, but most of the deposits are located in hard-to-reach places, remote from industrial areas. This is not so bad - a pipeline can be laid on land or on the seabed. And for transportation across the ocean, the gas is converted into a liquid state. At the same time, the volume is reduced by almost six hundred times, which makes it possible to use not only pipelines, but also LNG tankers of a special design for gas transportation

A logistics company is an enterprise that provides services for the transportation, processing and storage of goods. Rating of Russian logistics companies

Many foreign companies have been hiring third parties to provide services to perform non-core functions for them for a long period of time. This scheme is called "outsourcing". It means the involvement of a third party on a reimbursable basis in order to fulfill the tasks that the company faces. Outsourcing helps businesses to be more flexible, which allows them to make good profits

Gas production. Gas production methods. Gas production in Russia

Natural gas is formed by mixing various gases in the earth's crust. In most cases, the depth of occurrence ranges from several hundred meters to a couple of kilometers. It is worth noting that gas can form at high temperatures and pressures. In this case, there is no access of oxygen to the place. To date, gas production has been implemented in several ways, each of which we will consider in this article. But let's talk about everything in order

Liquefied gas is the fuel of the future

Global energy consumption is almost entirely based on the use of primary irreplaceable fossil fuels: coal, natural gas, peat, oil, and their derivatives, which are a wide range of petroleum products. Liquefied gas, considered one of the most promising and environmentally friendly fuels, can solve many of the energy and economic problems of mankind

The use of natural gas. Natural gas: composition, properties

What do we know about hydrocarbons? Well, perhaps something from the school curriculum in chemistry, and the word methane periodically flashing in the media … What do we know about natural gas, except for its explosive properties? What other use of natural gas, besides the well-known cooking and heating of residential buildings? What's new in the world of energy consumption and energy security?