2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:47

The sodium cation filter is a device that has become a savior from hard water in many ways. Previously, there was such a problem as too hard water, due to which appliances often broke down, and strong scale remained inside them. The first solution to this problem was the cationic cartridge.

General concepts of the essence of work

In order to make the water softer, as well as to avoid such a problem as a large amount of scale on the walls of containers, it is necessary to process the liquid with high quality. There are many ways to remove all excess impurities from this substance, but today the following two are most often used:

- The first option is chemical treatment, which is able to remove everything unnecessary from the liquid through certain reactions, but harmful chemicals are used for this.

- The second option is physical. In this case, it means that excessive calcareous water will be associated with irradiation, as well as neutralization of the performance of harmful ions.

However, it is worth noting that any of these methods has both its strengths and weaknesses. None of them are without flaws. To date, there is no ideal way to purify water from harmful impurities in such a way that there are no consequences.

Filter details

So, the oldest device that uses a sodium-cationite filter is an ion exchange filter. The device is very simple, consists of a small number of parts and has a simple principle of operation. Includes items such as:

- body and cartridge;

- recovery tank;

- s alt recovery tank;

- In some cases, there is an additional cleaner.

The sodium cation filter is made up of such a small number of items.

As for considering its principle of operation, it is immediately worth noting that there is a significant difference between a device for private use and industrial use.

Difference in hardware

The main difference in the principle of operation of a sodium-cationite filter for industrial and domestic purposes is that the first one can have sufficiently large dimensions and a multi-stage structure, while the second one can be no larger than an ordinary jug. It is worth mentioning that a main subspecies of such a device can be used in a private house. Since at home it is usually used to constantly purify and soften water for drinking, andalso in food, then replacing the cartridge will be a rather private task. On an industrial scale, sodium-cationite filters do not purify water to the extent that it can be drunk, and therefore they can be restored, not replaced. In such systems, filters of the type presented may be multi-casing. In other words, to have several cartridges so that if one fails, the others can continue to work instead.

At the end of the description of the device, you can add that it belongs to the group of chemical cleaners.

The principle of operation of the unit

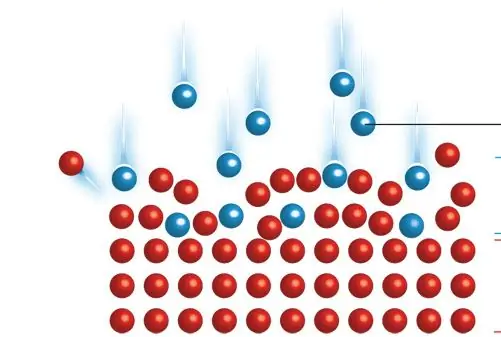

If we talk about the principle of operation of the sodium-cationite filter, then its whole essence lies in the filler, which is a special helium resin, which consists entirely of sodium balls. A special cartridge is stuffed with such a filler, and it is also capable of retaining all harmful impurities. This process is facilitated by a special reaction that occurs between sodium and s alts, and thanks to it, a crust is formed that retains harmful minerals. Substances such as calcium and magnesium will stick to the cation exchanger like metal to a magnet. From this it follows that the exchange of ions is the main purpose and device of the sodium-cation exchange filter.

When water, which is filled with harmful mineral s alts, meets resin balls filled with sodium, a quick replacement occurs. The main advantage of such an exchange is that it is a completely natural and very fast reaction that does not require the connection of any additionalequipment.

Sodium is swapped with minerals, which, in turn, adhere to the surface of the cartridge thoroughly. Another great feature is the ability to regenerate sodium cation filters, namely the restoration of these cartridges.

Purpose of the unit

A large amount of scale on appliances creates a fairly large number of problems. Therefore, there is no doubt about the need for such devices that are capable of softening water. Best of all, the purpose of sodium-cation exchange filters is revealed in cases where it is necessary to filter liquid for heating or heated appliances. This is due to the fact that the biggest drawback of the scale that covers the surface of such devices is that it transfers heat very poorly, actually stopping this process. Because of this, the equipment very often fails or cannot function normally.

The use of such a device as a filter will help to avoid such a problem almost completely.

To better understand the need for water treatment, a small example can be given. If you use the same pan for cooking all the time, using unfiltered liquid, a crust will form on the bottom. Scale works no worse than gypsum coating, without conducting heat. When the fire is turned on, the bottom of such a kitchen appliance will be heated to the limit, since it will not be able to go up through the coating. Even hardened cast iron cannot be used for a long time in such conditions. ATof course this will eventually lead to ruptures or melting of the bottom.

Review of device device

The sodium-cationite filter device is quite simple, especially in terms of design. You can consider it without any problems, even using the example of an ordinary drinking jug-purifier. The case for such models is most often made of plastic, which is usually transparent. This is done in order to make it more convenient to monitor the process of collecting liquid. Inside there is another container to which the cartridge itself is attached. Inside this cartridge is the helium sodium resin. It is worth noting that the throughput of such a filter is not too high, but it is quite enough, for example, for a family of three. From above, the device is closed with a lid so that nothing extra gets into the drinking water through the air. To filter the liquid, you just need to pour it into this container. Water will flow through the cartridge to the bottom, where it will be considered purified.

However, things are not always so simple. Such a filter can be a water treatment system, if necessary for the home. In this case, its design will be complemented by such devices as recovery tanks, as well as a control unit. In this case, the device itself will monitor the degree of clogging of the cartridge. If this happens, then a signal is given, and the fluid begins to go along the bypass. The system transfers the clogged cartridge to the recovery tank, in which the saline solution is prepared in advance. While one of the cartridgeswill be restored, the load on others will increase, but the device is designed for this.

Vulnerable Spot

As in any device, this filter has a weak point, due to which troubles can periodically arise. We are talking about a cartridge that will not allow you to operate the filter without stopping. It needs frequent maintenance, namely replacement or cleaning. In addition, the frequency of its maintenance directly depends on how polluted the water it has to process. Replacement should only be done if the filter is used for the production of drinking water, in all other cases it can be restored.

Restoration process

The main "repair" of sodium cation filters is the process of remanufacturing the cartridge, which can be carried out on the spot without shutting off the fluid supply. The recovery process takes place using a special saline solution. It is because of this that industrial plants are multi-stage, and each cartridge has its own recovery tank. Such automated installations have a special control panel, which receives a signal if the working element is too dirty and requires regeneration. You can also set the replacement time manually. To do this, you can specify the amount of time or the number of liters of water. The process itself is quite simple and is the opposite of what happens during cleansing. If during liquid handlingsodium gives way to a large amount of s alts, then during the reduction everything happens the other way around, and a strong flow of sodium is able to wash out the s alt. For this process, it is necessary to purchase not ordinary s alt, but specialized s alt, which contains a larger amount of sodium. By itself, it is cheap, but its consumption is large enough, which makes the recovery process not very cheap.

Use and maintenance

In terms of efficiency, the Na-filter is the best, however, a strong inconvenience is created by the fact that you have to constantly deal with its condition so that it can function at 100%. The unit itself costs quite a bit, but far from everyone likes the further constant replacement of the cartridge, and besides, you will have to spend all the time on its purchase. The filtering quality of a clogged and a fresh cartridge is very different.

Filtration stages

Currently, there are two types of devices, these are FIP filters of the first and second stages. The former are used for water purification at industrial enterprises, while the latter are used for the deepest softening and complete desalination of the liquid.

As for the characteristics of sodium-cation exchange filters, they are as follows for the first stage. Depending on the model, the working pressure can be from 0.4 to 0.6 MPa, the nominal diameter of the filter starts from 500 mm for the smallest model and ends at 3400 mm for the largest one. There is such a parameter as the height of the filter layer, which starts from 1000 and ends at 2500 mm. Performance is measuredcubic meters of water per hour and can be from 10 to 220. It is worth noting that the mass of such installations is large, and the lightest weighs 307 kg, and the heaviest 6.4 tons.

Second stage filters differ in that the working pressure of any model is 0.6 MPa, and the minimum diameter is 1000 mm, although the maximum diameter is somewhat smaller - 3000 mm. For any model, the height of the filter layer will be 1500 mm. But the minimum productivity of such plants, as well as the maximum one, is significantly higher and ranges from 40 to 350 m3/h. As for the mass, the minimum is slightly larger - 490 kg, but the maximum is significantly less, only 4.9 tons.

Conclusion

When buying a unit, please note that each device has a technical passport. Sodium cation exchange filters are always sold with accompanying documents. They contain all the information about the technical data of the device, according to which you can choose the right model.

These units are very efficient and relatively inexpensive. Their main problem and disadvantage is the need for constant replacement or regeneration of the cartridge for normal operation.

Recommended:

Ion implantation: concept, principle of operation, methods, purpose and application

Ion implantation is a low-temperature process by which the components of a single element are accelerated into the solid surface of a wafer, thereby changing its physical, chemical or electrical properties. This method is used in the production of semiconductor devices and in metal finishing, as well as in materials science research

Classification of engines. Types of engines, their purpose, device and principle of operation

Nowadays, most vehicles are powered by an engine. The classification of this device is huge and includes a large number of different types of engines

Driver controller: purpose, device and principle of operation

The use of a variety of vehicles today is very active. They all have in common that they need to be managed. The driver's controller is also designed for control. With it, you can remotely control the traction motor in braking or traction mode

Electric locomotive 2ES6: history of creation, description with photo, main characteristics, principle of operation, features of operation and repair

Today, communication between different cities, passenger transportation, delivery of goods is carried out in a variety of ways. One of these ways was the railroad. Electric locomotive 2ES6 is one of the types of transport that is currently actively used

Gas piston power plant: the principle of operation. Operation and maintenance of gas piston power plants

Gas piston power plant is used as a main or backup source of energy. The device requires access to any type of combustible gas to operate. Many GPES models can additionally generate heat for heating and cold for ventilation systems, warehouses, industrial facilities