2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Many people know that steel is a product obtained in the process of smelting other elements. But what? What is in steel? Today, this substance is a deformable alloy of iron with carbon (its amount is 2.14%), as well as a small proportion of other elements.

General information

It is worth noting that steel is an alloy that has exactly up to 2, 14% carbon in its composition. An alloy containing more than 2.14% carbon is already called cast iron.

It is known that the composition of carbon steel and ordinary steel is not the same. If the usual substrate includes carbon and other alloying (improving) components, then there are no alloying elements in the carbonaceous product. If we talk about alloy steel, then its composition is much richer. In order to improve the performance of this material, elements such as Cr, Ni, Mo, Wo, V, Al, B, Ti, etc. are added to its composition. It is important to note that the best properties of this substance are provided precisely by adding alloyed complexes, not one or two substances.

Classification

Spendclassification of the material we are considering can be based on several indicators:

- The first indicator is the chemical composition of the steel.

- The second is the microstructure, which is also very important.

- Of course, steels differ in their quality and production method.

- Also, each type of steel has its own application.

In more detail, the composition can be considered using the example of the chemical composition. On this basis, two more types are distinguished - these are alloyed and carbon steels.

Among carbon steels, there are three varieties, the main difference of which lies in the quantitative content of carbon. If the substance contains less than 0.3% carbon, then it is classified as low-carbon. The content of this substance in the region from 0.3% to 0.7% translates the final product into the category of medium carbon steels. If the alloy contains more than 0.7% carbon, then the steel is classified as high-carbon.

With alloy steels, things are about the same. If the composition of the material contains less than 2.5% alloying elements, then it is considered low-alloyed, from 2.5% to 10% - medium-alloyed, and from 10% and above - high-alloyed.

Microstructure

The microstructure of steel differs depending on its condition. If the alloy is annealed, then its structure will be divided into carbide, ferritic, austenitic, and so on. With a normalized microstructure of the substance, the product can be pearlitic, martensitic or austenitic.

The composition and properties of steel determine whether a product belongs to one of these three classes. The least alloyed and carbon steels are the pearlitic class, the medium ones are martensitic, and the high content of alloying elements or carbon translates them into the category of austenitic steels.

Production and quality

It is important to note that an alloy such as steel may include some negative elements, the high content of which worsens the performance of the product. These substances include sulfur and phosphorus. Depending on the content of these two elements, the composition and types of steel are divided into the following four categories:

- Private steel. This is an alloy of ordinary quality, containing up to 0.06% sulfur and up to 0.07% phosphorus.

- Quality. The content of the above substances in these steels is reduced to 0.04% sulfur and 0.035% phosphorus.

- High quality. Contains only up to 0.025% of both sulfur and phosphorus.

- The highest quality alloy is assigned if the percentage of sulfur is not more than 0.015, and phosphorus is not more than 0.025%.

If we talk about the production process of an ordinary alloy, then most often it is obtained in open-hearth furnaces or in Bessmerov, Thomas converters. This product is poured into large ingots. It is important to understand that the composition of steel, its structure, as well as its quality characteristics and properties are determined precisely by the method of its manufacture.

To obtain high-quality steel are also usedopen hearth furnaces, however, the smelting process is more stringent in order to obtain a quality product.

The melting of high-quality steels is carried out only in electric furnaces. This is due to the fact that the use of this type of industrial equipment guarantees an almost minimum content of non-metallic additives, that is, it reduces the percentage of sulfur and phosphorus.

In order to obtain an alloy of especially high quality, they resort to the method of electroslag remelting. The production of this product is possible only in electric furnaces. After the end of the manufacturing process, these steels are always obtained only alloyed.

Types of alloys by application

Naturally, a change in the composition of steel greatly affects the performance of this material, which means that the scope of its use is also changing. There are structural steels that can be used in construction, cold forming, case hardening, temperable, high strength, and so on.

If we talk about building steels, then they most often include medium-carbon and low-alloy alloys. Since they are mainly used for the construction of buildings, the most important characteristic for them is good weldability. Case-hardened steel is most often used for various parts, the main purpose of which is to work under conditions of surface wear and dynamic loading.

Other steels

To other types of steel can be attributed improved. This type of alloy is used only after heat treatment. The alloy is subjected to high temperatures for quenching, and then subjected to tempering in any environment.

The type of high-strength steels includes those in which, after selecting the chemical composition, as well as after undergoing heat treatment, the strength reaches almost a maximum, that is, approximately twice as much as that of the usual type of this product.

Spring steels can also be distinguished. This is an alloy that, as a result of its production, has received the best qualities in terms of elastic limit, load resistance, and fatigue.

Stainless steel composition

Stainless steel is alloy type. Its main property is high corrosion resistance, which is achieved by adding an element such as chromium to the composition of the alloy. In some situations nickel, vanadium or manganese may be used instead of chromium. It is worth noting that by melting the material and adding the necessary elements to it, it can acquire the properties of one of three grades of stainless steel.

The composition of these types of alloy, of course, is different. The simplest are conventional alloys with increased corrosion resistance 08 X 13 and 12 X 13. The next two types of this corrosion-resistant alloy should have high resistance not only at normal, but also at elevated temperatures.

Recommended:

Food stainless steel: GOST. How to identify food grade stainless steel? What is the difference between food stainless steel and technical stainless steel?

The article talks about grades of food grade stainless steel. Read how to distinguish food stainless steel from technical

Montmorillonite clay: mineral composition, properties, extraction and applications

Montmorillonite clay is actually a mineral that is very plastic, hence its name. The breed was first mined in France. Currently, a large number of deposits have been developed around the world. Montmorillonite has excellent adsorbing properties. It easily absorbs water and various components, increasing in size up to 20 times. Currently, the mineral is used in many industries

Corrosion resistant steel. Steel grades: GOST. Stainless steel - price

Why metal materials break down. What are corrosion-resistant steels and alloys. Chemical composition and classification according to the type of stainless steel microstructure. Factors affecting pricing. Steel grade designation system (GOST requirements). Application area

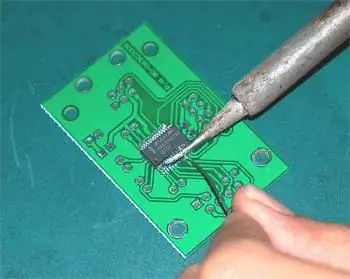

Solder for soldering copper, aluminum, brass, steel, stainless steel. Solder composition for soldering. Types of solders for soldering

When it is necessary to securely fasten various solid joints together, soldering is most often chosen for this. This process is widespread in many industries. We have to solder and home craftsmen

440 steel - stainless steel. Steel 440: characteristics

Many people know 440 steel. It has established itself as a reliable, anti-corrosion, time-tested hard material, which is most often used for the manufacture of knives for various purposes. What is the secret of this alloy? What are its chemical, physical characteristics and applications?