2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Not in all situations, you can use a welding machine that connects to a source of electricity. Especially if it is building a room from scratch. For such cases, the welding unit is designed. This is a high-tech element, without which it is simply impossible to do at production facilities. Often, these units are built on the basis of the chassis and are indispensable when it is necessary to perform outdoor work. Also, it is impossible to do without such a device at construction sites and large industries. These units are a combination of a welding machine and a generator. The device can be used for metal cutting and welding.

General information

The welding unit differs from traditional devices in mobility and independence from electricity. Also, this equipment can be easily transported by hand or by road.

Device on the chassis performs well in the field - on the street. This can explain the moment why an autonomous welding unit is designed, among other things, for operation in difficult and extreme conditions - rain, wind,summer heat.

These units are arranged from two nodes. This is the engine that is responsible for generating the power supply and the generator. The task of the latter is to generate the necessary current. In addition, some models of autonomous welding devices can be equipped with current generators, devices for heating soil or concrete, devices that allow you to adjust the welding current, a plasma-air cutting unit, and mechanisms for drying wet electrodes.

Types of mobile welding equipment

There are three types of aggregates. They differ in the transformer - it can be collector or valve. Also, the equipment differs in the type of drive. The generator can be gasoline, diesel or electric. Also, the installation may have wheels or be stationary.

The engine is equipped with air or liquid cooling. Working current - direct or variable. There is also a welding unit for two-, one- or multi-operator. Rated current - from 250 to 500 A. Devices equipped with a 4004 gasoline engine are offered at very reasonable prices, but have one drawback. The engine needs quality fuel to run. Equipment based on a diesel engine has a higher cost. However, the quality of the fuel does not matter here. The device can operate efficiently on inexpensive fuel. The diesel welding unit is unpretentious in operation and can work properly even at sub-zero air temperatures.

Device

To understand how the equipment works, toFor example, a welding unit of the SAK type, it is necessary to disassemble the device in detail. Structurally, the system is a modern and technological stuffing and a durable case. Highly specialized units, as well as universal equipment, consist of two basic components - an engine and a generator.

In addition to the basic units, the system consists of a fuel tank, control and measurement instruments, a control panel, batteries, rheostats for adjusting the current strength, as well as a niche for tools in the unit body.

The main as well as additional systems are rigidly fixed on a frame made of strong metal. The housing is designed to protect the structure. It protects the equipment from the impact of various negative factors, adverse weather conditions and mechanical damage. Due to such a reliable design, it is possible to operate the welding unit in any weather - in snow, rain, summer heat or frost, without fear that water will penetrate into the device. The whole design is carefully thought out. For example, on the side and on the back there are special doors through which you can conveniently access the internal systems. Also, due to these doors, repairs are greatly facilitated. For greater comfort in transportation and operation, mobile welding units type D144 can be equipped with a spotlight.

Features of the welding machine

Absolutely any welding machine works on the same basic principle. It is specially designed so that the system outputsmaximum efficiency. That is why welders must know the theoretical part well.

Modern manufacturers offer a wide range of equipment - according to reviews, there is always something to choose from to solve certain problems. At the same time, units that are identical in appearance will differ in the type of key units. Although the scheme by which they work will be the same. The circuit is necessary for supplying with stable voltages. Without this, it is impossible to talk about any stable operation of the device.

In addition, an electric arc is provided - without it it is impossible to get neat and professional seams. But they are important not only from an aesthetic, but also from a technical point of view. Different brands of equipment use different circuits to maximize performance.

Wheel unit ADD

The most convenient option, according to most welders, is the ADD 4004 welding unit. This modification is in demand because it is equipped with wheels and can be easily transported to the place of work by any means. Reviews say that the wheels make it possible to drag the unit from one workshop to another without the presence of a car by two people. If you need to deliver the system over long distances, then any car will do.

The chassis greatly enhances the load-bearing performance of the stand-alone welding machine. Its mass is quite large, and due to the chassis, the pressure on the soil is leveled. Therefore, such a system can be installed even inwetlands.

Possibilities of petrol units

Generators that run on gasoline, as you can see from the reviews, are used most often. The power of such equipment ranges from 0.5 kW to 100 kW. Among the advantages - simplicity and versatility, low weight, low price. Also, reviews note the ability to carry out welding work at low temperatures.

However, there are also disadvantages. Reviews note a relatively short service life and high fuel consumption. Depending on the manufacturer and model, gasoline generators can operate efficiently from 500 to 3000 hours. As for fuel consumption, about 5.5 liters of fuel are needed to produce 1 kW of energy. That's a lot.

Diesel devices

Reviews say that devices of this type can connect metals even under high loads, which gasoline devices cannot provide. Such a mechanism is not suitable for use in everyday life and for private use. The initial power of this technique is from 5 kW.

Among the advantages are the high characteristics of welding units of this type, stability, the ability to work under heavy loads. Motor resource - up to 40,000 hours. Another big plus is fuel consumption. If a gasoline generator required 5.5 liters of fuel, then no more than 300 ml will be consumed per 1 kW.

But there are also disadvantages. It's highcost (often 3-5 times more expensive). Due to the peculiarity of the fuel, the engine does not start well at low temperatures. In this regard, gasoline units are more practical.

Market Watch

A large selection of such equipment is presented on the modern Russian market. Mostly these are gasoline and diesel mobile devices for domestic use. Often these are universal units that can be used for any type of welding work. For those who want to purchase such welding units, the price starts from 50 thousand rubles for gasoline models. Model ADD 4004 is offered at a price of 188 thousand rubles. The maximum cost is 850 thousand rubles.

Recommended:

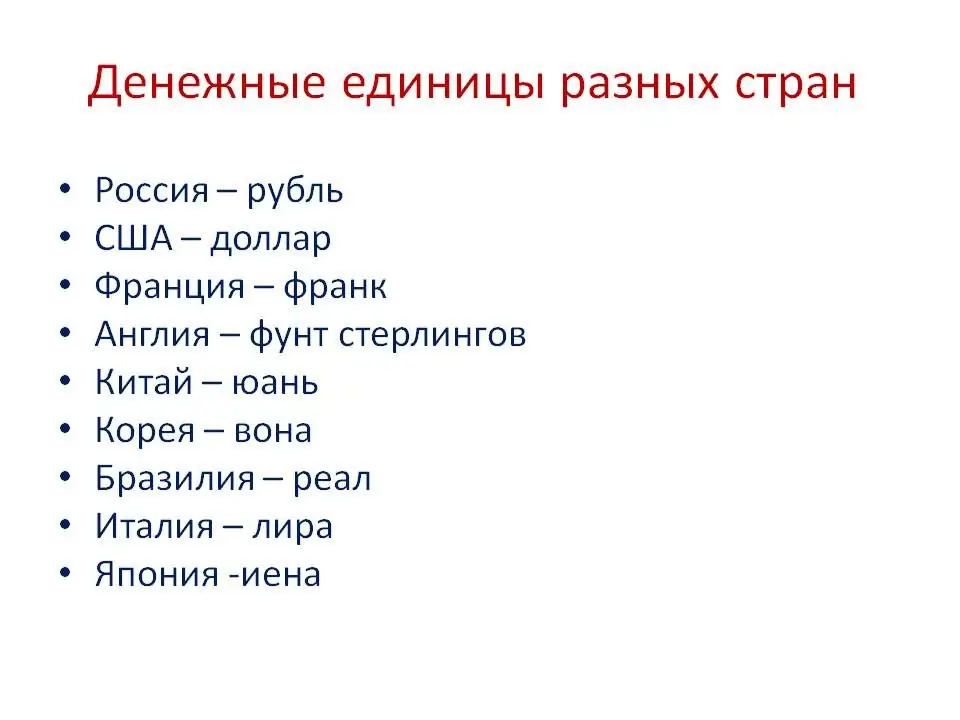

Monetary unit - what is it? Definition of the monetary unit and its types

The monetary unit serves as a measure for expressing the value of goods, services, labor. On the other hand, each monetary unit in different countries has its own measure of measurement. Historically, each state sets its own unit of money

Warehouse program: overview, description, application, types and reviews

One of the effective ways to reduce the costs of the enterprise is to increase the efficiency of the implementation of warehouse tasks. This goal is achieved through process automation. It gives the company a significant advantage in the market

Disk harrow mounted, sectional and trailed. Disc harrow: overview, characteristics, types and reviews

Pre-sowing tillage is unimaginable without a disc harrow - an agricultural tool that can simultaneously perform several operations: leveling the soil cover, loosening the surface, which prevents drying, destruction of the crust and destruction of weeds

Welding consumables: definition, characteristics, manufacture, storage. Main welding material

Main types of welding consumables, features of storage of explosive gases, characteristics of electrodes depending on the material and other parameters

Flux for welding: purpose, types of welding, flux composition, rules of use, GOST requirements, pros and cons of application

The quality of the weld is determined not only by the ability of the master to organize the arc correctly, but also by the special protection of the working area from external influences. The main enemy on the way to creating a strong and durable metal connection is the natural air environment. The weld is isolated from oxygen by a flux for welding, but this is not only its task