2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

Currently, a lot of work is carried out using welding. For this reason, oxygen hoses have become a highly sought-after material, and they are also easy to transport.

What is a sleeve

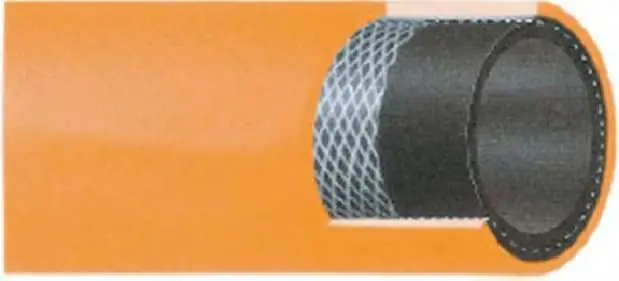

A conventional oxygen hose is a flexible long hose, which is made from a layer of cord thread, protected on both sides by several layers of rubber compound. This product is the most demanded when working with welding. Of course, this material has a very narrow application, but, despite this drawback, today it is one of the most popular rubber products. The main purpose of this hose is the filling or supply of gases. Most often, this function is required when carrying out any industrial work.

Scope of the hose

Oxygen sleeves, for example, in production, are indispensable in order to supply substances such as oxygen, propane, acetylene and atmospheric air, which come from stationary devices. Such stationary devices can be an oxygen line, an acetylene or propane cylinder. Delivery is carried outfrom these products to the place where industrial work is carried out. In addition, oxygen hoses are successfully used in the manufacture of medical equipment. Most often, you can see the use of such a hose in a medical life support system that supplies oxygen, or in a special suit, the main task of which is also to supply oxygen from a cylinder to a mask.

Customer reviews of this item are very different. Some buyers are quite satisfied with the purchase, they say that the hose withstands stress, does not tear or crack. However, there are other claims as well. For example, they say that an ordinary red acetylene hose, designed for 6 MPa, does not withstand pressure in some cases and breaks. If you look at reviews of conventional rubber hoses, some buyers say that they often crack.

Design

The oxygen sleeve consists of two components. The first element is the inner rubber layer, the second element is the cord carcass, which is made of cotton fiber or impregnated or unimpregnated fibers of the outer rubber layer. It is also important to note that if any visible damage to the sleeve is found, its use is strictly prohibited. It is worth noting that these products have different colors. Depending on the color of the hose, the scope of its application changes:

- red hose is used for work with acetylene, propane, butane, as well as city gas and has a class 1;

- second class is the yellow sleevecolor, which is intended for the transport of liquid fuels;

- The blue oxygen sleeve is class 3 and is used to transport oxygen.

But it is important to note that it is allowed to paint these products in black, regardless of which class they belong to. In this case, a colored risk (groove) is used, which determines whether this hose belongs to any class.

Used for designation:

- one dash is the first class;

- the second class is, respectively, two dashes;

- third grade - three.

The standard specifications for these hoses are:

- internal diameter of the oxygen hose - 9 mm;

- hose OD 22mm;

- working pressure inside the product can reach 6.3 MPa;

- GOST, according to which this product is manufactured - 9356-75.

Sleeve testing

The production of this product is mandatory for its passage through laboratory as well as production testing. Once a new product is developed and the manufacturing process is fully developed, the product is sent for production testing. This test program for oxygen hoses includes verification of compliance with the technical requirements that apply to this product. After the completion of the test phase, a decision should be made on whetherwhether it is worth using this development, and whether to establish the production of this particular type of product.

Laboratory testing

It's worth starting with the fact that absolutely all materials are subjected to laboratory tests, which will subsequently be used to create an oxygen or oxygen-propane hose. The tests are carried out on the ingredients that will make up the rubber layer of the hose. All reinforcing materials from which the power part of the product is made will also be tested.

It is also important to note that after the manufacture of the rubber compound, glue or paste, before putting them into further production, one more laboratory test is carried out, the purpose of which is to find out whether the resulting material meets all the norms and requirements available in the regulatory documentation. The first thing that is evaluated is the elastic-strength characteristic. The physicochemical parameters of the resulting mixture are also evaluated. They must comply with all norms and requirements, which are prescribed in GOST 270-75.

In addition to determining these characteristics, they also check the hardness and elasticity of the resulting rubber, its resistance to frost or heat. Another factor that is also checked is the resistance of the hose to the gas that will be used.

Production testing

It is important to know that in domestic production there is no standardized procedure for testing this product. Most often, this type of verification is reduced to the fact that they evaluate the integrityof the resulting product, as well as selectively control the dimensions of the hose. For those products that will work under conditions of pneumatic or hydraulic loading, it is mandatory to pass a test for tightness and safety margin.

To test the function of a pressurized hose, fill it with working fluid until the air is completely expelled. After that, under the action of the desired pressure, the hose can withstand the required amount of time. Options are allowed when, instead of the usual check in time, it is brought to the moment of rupture. If fabric sleeves are taken into account, then their tests are carried out in accordance with GOST 6867. It is important to determine the strength of the bond between fabric and rubber structural elements.

Oxygen hose 9mm, GOST 9356-75

This state standard establishes the norms and requirements for this type of product. From the technical requirements, the following can be distinguished:

- They should either consist of a rubber inner layer and a cotton frame, or be based on impregnated and non-impregnated chemical fibers, the outer layer should be rubber.

- The same GOST also establishes the requirements for the colors of this product in relation to its working environment.

- The height of the reefs at the hose should be from 0.2 to 0.3 mm, but their width - from 0.4 to 0.5 mm. The distance between the groups of dashes is from 3 to 4 mm.

- It can be noted that if the hose belongs to the third class, works with oxygen, and it is painted black, then at a working pressure of up to 4 MPa, that is40 kgf/cm2, color stripes or dashes optional.

Marking, storage, delivery

It is necessary to apply marking on those hoses that will be operated in cold climates, taking into account the regulatory documentation belonging to these facilities. For delivery or storage, all sleeves are tied and stacked in bays. The diameter of the resulting bay must be at least 300 mm. It is necessary to tie such bays with a fabric tape, the width of which is from 30 to 40 mm. In addition, such a tape must be fixed in at least three places. The tape is made of calico or other material that can be used for dressing and ensures the safety of the sleeve packaging.

Recommended:

Oxygen converter: device and steelmaking technology

In the processes of obtaining high-strength steels, alloying operations and modification of the base composition play an important role. The basis of such procedures is the technique of adding metal impurities of various properties, but gas-air regulation is also of no small importance. It is this technological operation that focuses on the operation of the oxygen converter, which is widely used in metallurgy in the production of steel alloys in large volumes

Oxygen sleeve: description, GOST, types and diameter

Currently, people are quite actively using various gas or oxygen for their own purposes. Since it is necessary to transport a gaseous substance in a completely sealed environment, hoses have been developed, which are called oxygen hoses

Oxygen cylinders. Proper refueling is the key to he alth and safety

One of the most important and dangerous preparations for diving is the correct filling of oxygen cylinders. The article tells how to properly fill oxygen cylinders and why there are cases of explosion of oxygen cylinders

Railway track is Definition, concept, characteristics and dimensions. Train dimensions and features of track facilities operation

Traveling by train through cities and towns, you can learn a lot of interesting and amusing things about the world of the railway. More than once, traveling people have asked themselves questions about where this or that railway track leads? And what does the engineer who manages the train feel when the train is just starting off or arriving at the station? How and from where do metal cars move and what are the ways of the rolling stock?

Dimensions of wooden railway sleepers. Reinforced concrete sleeper: dimensions

The production of railway sleepers in the Russian Federation is regulated by strict state standards. This applies to both wooden and reinforced concrete structures. What are the specifics of the standards governing the dimensions of both types of sleepers?