2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:43

Everyone understands that the construction of any facility is a significant waste of money. Many people who build any objects are trying to find options for performing work that would not be very expensive, but would provide decent quality. The use of facing blocks has become quite common today, as this option helps to save money. In addition, this material has a number of characteristics that are useful in the operation of the building.

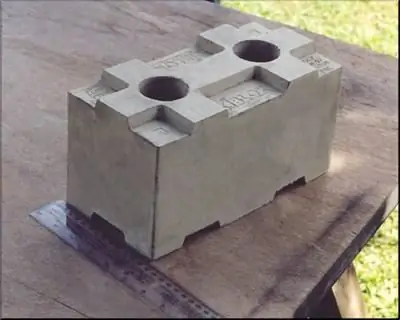

Expanded concrete

A fairly common type of such material has become a facing expanded clay concrete block. Today, technology allows you to create many building materials in industrial conditions. This type of product is also artificial. To make this type of block, foamed and baked clay is used. Inside the structure of each block contains porous-type balls. Despite this, the load that the product can withstand is quite high. In addition, the presencevoids inside such a facing block allows it to perfectly retain heat. Thanks to these qualities, expanded clay is considered a fairly suitable material for construction and cladding.

Varieties of blocks

Currently, there are several types of facing blocks. They are divided into three types, depending on their purpose:

- Slotted.

- Void.

- Full-bodied.

It is worth noting that it is much easier to build a wall from such material than from ordinary bricks. As for the cost of blocks, it depends on the design of the product itself. The most expensive is a solid block. This is understandable, since the largest amount of raw materials is spent to create it. Most often, such blocks are used only for mounting walls that serve as load-bearing.

It is also worth noting that houses made of claydite-type concrete facing block can have a minimum thickness of 40 cm, and when laying brick walls, the wall thickness must be at least 60 cm. This advantage became possible because expanded clay concrete has the best sound and heat insulation quality.

Wall cladding

As for the facing block made of such material, its appearance can reproduce brickwork, plaster or even marble. In addition, the advantage of block cladding is that it eliminates the need for additional finishing of the house. This saves a lot of materialfunds.

Another rather significant advantage of the cladding block is that manufacturers produce half and even corner models, which greatly simplifies the installation process. In addition to these two advantages, there are a number of other positive aspects. For example, such laying of facing blocks will be completely environmentally friendly. This building material is able to perfectly withstand the effects of fire and dampness, perfectly retains heat, does not rot, and is frost-resistant. In addition, he has a rather attractive appearance.

Brick facing type

Today, ceramic-type facing brick blocks have also become quite common material. This product is also made from clay, but from one that undergoes a firing procedure in a variety of conditions. Such types of production as plastic and semi-dry molding are common. Most often, it is the first type of production that is used, since it allows better mechanization of the entire process, which significantly increases productivity and increases the stability of the technology.

The difference between an ordinary brick and a facing ceramic block is that the first material performs only one function, and the second several at once. The cladding raw material not only protects the walls and insulation, but also creates a decorative type shell, which makes the appearance of the building more attractive.

Pros and cons of facingbrick

Among the advantages of facing bricks and ceramic blocks, the following parameters stand out:

- High strength.

- Good resistance not only to frost, but also to moisture.

- The material is considered environmentally friendly and has good heat saving performance.

- Another good plus is the complete lack of flammability.

- The life of the unit is quite long.

However, not without flaws:

- Houses made of ceramic brick cladding block are heavy because the block itself is quite heavy. Because of this, additional pressure is created on the foundation of the structure.

- The process of laying such material is much more complicated, which increases the requirements for the qualification of a bricklayer who will be engaged in this type of work. This is most noticeable from the front side of the house, where it is often necessary to lay out ornaments.

- Both the material and its installation are quite expensive.

Types of facing bricks

Today, there are 4 types of facing bricks, each of which differs in production technology.

The first type is clinker. It is considered the most durable among other facing blocks. For manufacturing, it is necessary to carry out the firing procedure at a temperature of 1900 degrees Celsius. The material practically does not absorb water, which has a positive effect on the service life, but also complicates the masonry process.

Second view -These are hyper-pressed cladding blocks. They are made without a firing procedure, but under sufficiently high pressure. As for the quality, it is somewhat worse than those produced by firing. There are some problems with thermal conductivity due to too high a density. The biggest advantage of this type of facing block is that it has perfectly even edges and shape.

The third kind is a porous brick. To create such a structure, it is necessary to lay sawdust in the raw material at the formation stage. During firing, they will burn out, forming many small cavities. The advantage of this material is that its weight is reduced. However, the sound transmission is increased. But it also has better heat-saving properties.

The fourth type is an engobed brick. In another way, this facing material is called two-layer or colored. During production, a very thin layer of colored clay is applied to the dried block. Its thickness is only 0.2-0.3 mm. After passing through the firing procedure, such material acquires a matte color layer.

Material specifications

Ceramic brick blocks can be hollow, solid, face or oven. They can also have significantly different surfaces. It can be smooth, rough, glazed, figured, shaped. It is worth saying that the technology for the production of such blocks does not allow reproducing the same color by 100%. For this reason, if it is necessary to carry out layinglarge area, then you need to purchase blocks from the same lot.

As for the main technical characteristics of brick blocks, they are as follows:

- As for the length, it is the same for everyone and is 250 mm.

- The width is 120mm, however for hyper pressed bricks the width can also be 60mm and 90mm.

- The height of the blocks can be 68, 88 and 138mm.

- Material density ranges from 1000 to 2100 kg/m3.

- Porosity of blocks starts from 6% and can reach 45%.

- The frost resistance of blocks also fluctuates. It can be from 15 to 100 cycles.

- As for the strength grade, it is from 75 to 1000, and the thermal conductivity is 0.3-1.16 W/m2°C.

Choice of facing bricks

As for the choice of a suitable material, here it is necessary to be guided by the following points:

- Facing raw materials must have the correct shape and geometry (if it is not a "torn" block).

- The edges should be fairly even and clear, without any defects and chips.

- The shade of all blocks should be uniform and not have any spots.

- There should not be any cracks on the edges.

- Minimum compressive strength should be 20%.

It is very important to correctly calculate the amount of facing material that will be required during the construction of the building in order to select the right batch. If the material has to be bought in addition, you may not find identical in color and some other characteristics. This is becauseeven a slight change in temperature during production will result in a significant change in performance.

Ragged facing block

Blocks of this type are very popular, as the decoration of buildings with this material allows you to create a building that is very similar to the medieval one, for example.

Such a material is called "torn" because one of the edges breaks in the process of its creation. This is done in order to give the most natural appearance to an artificial product. In order to create such a material, granite, slag, expanded clay, brick, and glass are used as raw materials. The components are typically 3 to 5 mm in size. Then they are mixed with cement and water. Modifiers and dyes are used as additives.

Varieties of broken blocks

Today, there are three types of facing material in this category.

The first one is already familiar to us hollow or full-bodied. As for the application, the first type is used more for decorative decoration inside the building or for facade decoration, for the construction of a fence, and so on. Solid is suitable for the construction of various load-bearing structures.

Materials can be made in different shapes, for example, in the form of a wedge, a regular parallelepiped.

Such blocks can also be produced with standard dimensions of 250x120x65 mm. The size may fluctuate. It depends on what exactly the facing block will be used for.

Regardingbroken brick properties, they are as follows:

- No susceptibility to rotting, burning, corrosion.

- Moisture resistant.

- High strength.

- Sustainable.

- Does not fade or fade in sunlight.

Recommended:

Leasing: advantages and disadvantages, main function, classification, tips and tricks

Definition, functions, advantages and disadvantages of leasing as a form of financial activity. General information, classification of leasing relations. Pros and cons of buying a car on lease, as the most common product. Recommendations for choosing a leasing company

Foam block: foam block dimensions, history of appearance and application prospects

Each movement of the bricklayer is performed at a certain speed. An ordinary clay brick weighing about 3 kg or a large foam block of the same mass will be installed in the wall in the same time. But the dimensions of the foam block are eight or even twelve times the size of a brick, which dramatically increases the speed of masonry. Another important advantage of a light and warm building material is that it requires an adhesive rather than a complex cement-sand mortar

Collective investments: concept, types and forms, advantages and disadvantages

Collective investment is a type of trust management with a low entry threshold that allows small investors to invest in the stock market, real estate market, precious metals and others, making a profit from investing their money. This is an investment of the joint capital of investors, which makes it possible to earn money by significantly increasing their capital

Main types and types of business plans, their classification, structure and application in practice

Each business plan is unique, because it is developed for certain specific conditions. But you need to familiarize yourself with the features of various types of business plans in order to understand their key features. Experts recommend doing this before compiling your own similar document

Mineral wool density: classification, advantages and disadvantages, purpose of mineral wool and application

Mineral wool is the most popular type of insulation for an apartment or house. Today it is used by everyone, from builders to the owner of the apartment, who wanted to insulate the room. The simplicity of its installation allows you to immediately insulate the entire house (ceiling, walls, floor). We will study the features and characteristics of the named material further in the article