2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

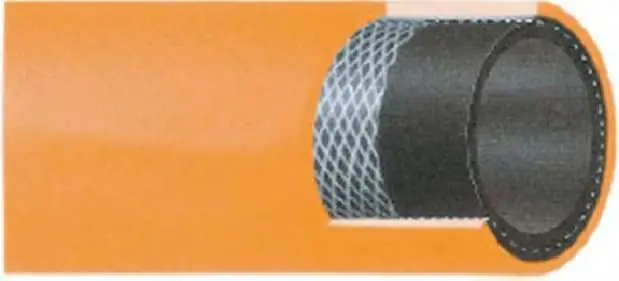

Oxygen sleeve is a flexible type hose, for the production of which a material such as cord thread is used. As an additional material that protects this thread, rubber mixtures are used, which are applied to the sleeve from all sides.

Description

This product is indispensable if you need to carry out welding work, especially if you also mean transporting welding gas from one place to another. It should be noted that the application profile of the oxygen hose is quite narrow, but at the same time it is this rubber product that has become the most widely used among others. It is this type of hose that is considered the most in demand among all other devices, the purpose of which is the transportation of a gaseous substance on an industrial scale.

Features

Oxygen hoses are most often used in production processes if there is a need to deliver a gas such as acetylene or propane, oxygen or atmospheric air. Transportation is most often carried out from a cylinderwith the desired substance or from the line, to the point where welding is carried out. Without the use of this hose, it would be impossible to imagine the operation of welding machines. Another area of use of oxygen sleeves is the production of medical equipment or special suits that require the supply of oxygen from a cylinder to a mask. Vivid examples are suits for divers and astronauts. The design of this hose is quite simple. It has an internal rubber layer, after which a frame is created from cord, cotton fiber, fibers pre-impregnated with a special agent. It is very important that if, before the start of operation, during the inspection, any defects were noticed that led to a violation of the integrity of the product, then it is forbidden to operate such a product.

Classes

Currently, there is a division of the oxygen hose into three categories. A hose belongs to one category or another depending on the purposes for which it can be used.

- The first category of hoses is intended for the transportation of acetylene, butane, propane at a pressure of not more than 0.63 MPa.

- The second category of rubber products includes those hoses through which gasoline, kerosene or mixtures based on these substances are supplied, with a pressure of 0.63 MPa.

- The third category of oxygen hoses are devices for transporting oxygen with pressure up to 2 MPa.

It is important to note thatoperation of any of these three categories of hoses is expected at a temperature not exceeding 70 degrees Celsius. Do not use standard oxygen hoses if the temperature drops below -35 degrees Celsius. However, there are specialized hoses that have been specially designed for operation in cold regions. The maximum possible operating temperature of such devices is -55 degrees Celsius.

Marking

In accordance with GOST oxygen hoses number 9356, a symbol for the hose is set. This document establishes the rules for labeling these devices. Each hose must have in its designation the class of the hose, its diameter indicated in millimeters, the pressure value in MPa and an indication of the climatic version of the hose. Those rubber products that are operated only in temperate climatic zones do not have additional markings. But those oxygen hoses that can be used in cold climates are additionally marked "HL".

Types of hose

Depending on the scope of application, the sleeves are painted in different colors. Hoses belonging to the first category, that is, used to transport gases with a pressure of 0.63 MPa, have a red color.

The second category is colored yellow.

The most common is the blue 9mm oxygen sleeve.

GOST 9356 alsoregulates the painting of the hose in black. But if the external execution is of this color, then there must be two stripes on the sleeve, made in the color to which the fixture belongs.

Quality control of finished products is carried out through visual inspection. A quality product is considered to be one that does not have cracks, bubbles or folds on its inner rubber side, and there are no bubbles, delaminations on the outer side, and there are also no bare spots, that is, without a power frame. The quality of the product that was produced is compared with a control sample. At the manufacturing plant, acceptance is carried out in batches. A batch is considered to be the length of an oxygen hose of one class, not exceeding 2000 m. In addition to visual quality control, the hose also passes a leak test under hydraulic pressure, a test of tensile strength, as well as the resistance of the outer layer to the aggressive effects of gasoline. This stage of verification is carried out only for those products that will belong to the second category.

Basic parameters according to GOST

This document establishes all the rules for the manufacture and subsequent storage, labeling and transportation of oxygen hoses. All the main parameters for these devices are indicated in GOST. For example, a hose with a working pressure of 0.63 MPa (6.3 kgf/cm2) should have a nominal inner diameter of 6.3 mm and an outer diameter of 13 mm. If we talk about products designed for transporting oxygen, that is,pressure is 2 MPa (20.0 kgf/cm2), then the inner diameter of the oxygen hose is 8 mm, and the outer diameter is 16 mm. It is also worth noting that GOST regulates the production of hoses designed for a pressure of 4 MPa (40.0 kgf/cm2). With this indicator, the inner diameter of the hose is 6.3 mm, but the outer diameter reaches 16 mm.

It is worth noting that in the manufacture of sleeves, it is necessary to coordinate the length of the batch directly with its customer.

Specifications

GOST 9356 also establishes the substances from which oxygen hoses can be produced. This includes those materials that were previously indicated, such as an inner rubber layer, a power frame made of cord thread, etc. Color and categorization is also carried out in accordance with the rules of GOST. All hoses that are allowed to operate must be completely leak-tight under hydraulic pressure. Another important point is that each hose must have a minimum of three times the safety margin when ruptured by hydraulic pressure. The ends of these products must withstand tension without breaking in the radial direction. This is important because this pressure increases greatly when the sleeve is pushed onto the corresponding nipple. The price of an oxygen hose is from 50 to 75 rubles per 1 meter of the product.

Recommended:

Oxygen converter: device and steelmaking technology

In the processes of obtaining high-strength steels, alloying operations and modification of the base composition play an important role. The basis of such procedures is the technique of adding metal impurities of various properties, but gas-air regulation is also of no small importance. It is this technological operation that focuses on the operation of the oxygen converter, which is widely used in metallurgy in the production of steel alloys in large volumes

Oxygen cylinders. Proper refueling is the key to he alth and safety

One of the most important and dangerous preparations for diving is the correct filling of oxygen cylinders. The article tells how to properly fill oxygen cylinders and why there are cases of explosion of oxygen cylinders

Oxygen hoses: description, dimensions, GOST and reviews

Currently, a lot of work is carried out using welding. For this reason, oxygen hoses have become quite a popular material, and besides, they are easy to transport

Oxygen-free copper: features, benefits, applications

Copper is a mineral that lives in human life for many millennia. In ancient times, it was used mainly to obtain bronze, in an alloy with tin. In Latin, its name is Cuprum. It was given to him by the ancient island of Cyprus, which was one of the first places where copper was mined and smelted from mines

Durite sleeve: description, characteristics, types, diameter and dimensions

With the development of various industries, there was a need for a large amount of fuel, as well as its supply. To ensure the transportation of harmful substances, several methods were invented, one of which was the delivery of raw materials through a durite sleeve