2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:47

The head of any enterprise, regardless of the field of activity, dreams that profits grow and production costs remain unchanged. The "5S" system in production (in the English version 5S), which is based only on the rational use of internal reserves, helps to achieve this result.

This system was not created from scratch. Something similar at the end of the 19th century was proposed by the American Frederick Taylor. In Russia, this was done by the scientist, revolutionary, philosopher and ideologist A. A. Bogdanov, who published a book on the principles of scientific management in 1911. On the basis of the provisions set forth in it, the USSR introduced the NOT, that is, the scientific organization of labor. But the most perfect was the 5C system proposed by the Japanese engineer Taiichi Ohno and introduced by him at the Toyota Motor plant in production. What is it and why has the Japanese system become so popular?

The fact is that it is based on a simple principle that does not require costs. It consists inthe next - each employee, from the cleaner to the director, should optimize his part in the overall workflow as much as possible. This leads to an increase in the profit of production as a whole and to an increase in the income of all its employees. Now the baton of the introduction of the "5C" system has been picked up by enterprises all over the world, including Russia. In this article, we will try to convince skeptics that Japanese know-how really works, and absolutely in any field of activity.

The "5C" system in production, what is it

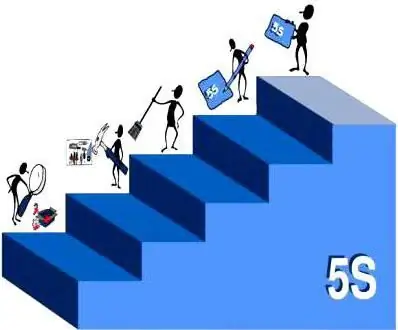

International 5S stands for five steps ("step" in English step). Some economists and promoters of a new attitude to work explain the name by the five Japanese postulates that are consistently implemented in the 5S system: seiri, seiton, seiso, seiketsu and shitsuke. For us, our native "5C" is closer and more understandable - five consecutive steps that need to be completed in order to achieve the prosperity of our production. This is:

1. Sort.

2. Keeping order.

3. Keeping clean.

4. Standardization.

5. Improvement.

As you can see, the "5C" system does not require anything supernatural in production. Perhaps that is why one can still meet distrust and a frivolous attitude towards her.

Stages of creating a system

The wise Japanese Taiichi Ono, who, thanks to the introduction of his methods at the Toyota plant, managed to rise fromengineer to CEO, noticed how many losses occur due to various inconsistencies and overlays. For example, some small screws were not put on the conveyor in time, and as a result, the entire production stopped. Or vice versa, the parts were supplied with a margin, they turned out to be superfluous, and as a result, one of the employees had to take them back to the warehouse, which means wasting their time on empty work. Taiichi Ohno developed a concept he called "just in time". That is, exactly as many parts as needed were now delivered to the conveyor.

Other examples could be given. The "5S" system in production also included the concept of "kanban", which in Japanese means "advertising sign". Taiichi Ohno suggested attaching a so-called "kanban" tag to each part or each tool, in which all the necessary information on the part or tool was given. Basically, it applies to anything. For example, to goods, medicines, folders in the office. The third concept on which the 5S system in production is based is the concept of "kaizen", which means continuous improvement. Other concepts were also conceived that were suitable only for highly specialized production processes. In this article, we will not consider them. As a result of all the innovations tested in practice, 5 steps have been formed that are applicable to any production. Let's analyze them in detail.

Sorting

Many of us have items on our desktops that, inbasically not needed. For example, old forms, unused files, drafts of calculations, a napkin on which there was a cup of coffee. And among this chaos there may be the necessary files or documents. The basic principles of the "5S" system involve optimizing your workflow, that is, making sure that time is not wasted searching for the right things among the rubble of the unnecessary. This is sorting. That is, at the workplace (near the machine, on the table, in the workshop - anywhere), all items are laid out in two piles - the necessary and the unnecessary, which must be disposed of. Further, everything you need is decomposed into the following piles: “used often and constantly”, “rarely used”, “almost not used”. This completes the sorting.

Keeping order

If you just disassemble the items, there will be no sense. It is necessary to arrange these items (tools, documents) in such an order that what is used constantly and often is in sight, or so that it can be quickly taken and easily put back. What is rarely used can be sent somewhere in a box, but a kanban tag must be attached to it so that after a while it can be easily and accurately found. As you can see, the "5S" system in the workplace starts with the simplest steps, but in fact it turns out to be very effective. And besides, it improves mood and desire to work.

Keeping clean

This third step is the most logical for many. We are taught to be clean from childhood. On thein production, it is also necessary, and not only the tables of office workers or cabinets in catering establishments, but also machines, utility rooms of cleaners should be clean. In Japan, employees take good care of their workplaces, they are cleaned three times a day - in the morning before work, at lunchtime and in the evening, at the end of the working day. In addition, their enterprises have introduced special marking of areas that allow them to observe order in production, that is, areas of finished products, storage of certain parts, and so on are marked with different colors.

Standardization

The principles of standardization were invented by Taiichi Ohno. They are also widely used by the modern 5S system. Production management, thanks to standardization, receives a wonderful tool for controlling all processes. As a result, the causes of delays from the schedule are quickly eliminated and errors that lead to the release of low-quality products are corrected. At the Toyota Motor plant, standardization looked like this: foremen drew up daily work plans, precise instructions were posted at the workplace, and at the end of the working day, special workers checked which deviations from the plan occurred during the day and why. This is the basic rule of standardization, that is, precise instructions, work plans and control over their implementation. Now many enterprises, for example, ENSTO plants in Estonia, are introducing a bonus system for employees who strictly comply with the provisions of the 5C system and, on the basis of this, increase their productivity, whichis a great incentive to adopt this system as a way of life.

Improvement

The fifth step, which completes the "5S" system in production, is based on the concept of kaizen. It means that all employees, regardless of their position, should strive to improve the process of work in the area entrusted to them. The philosophical essence of kaizen is that our whole life gets better every day, and since work is a part of life, it should not remain aloof from improvements either.

The field of activity here is wide, because perfection has no limits. According to the concepts of the Japanese, workers themselves should want to improve their production process, without instructions or coercion. Now many organizations are building teams of workers who monitor product quality, teach their positive experience to others, and help achieve excellence.

Basic mistakes

For the "5C" system to start working, it is not enough to organize it or hire employees who will force their colleagues to implement it. It is important that people realize the usefulness of this innovation and accept it as a lifestyle. The introduction of the "5S" system in Russia in production is facing difficulties precisely because our Russian mentality is different from the Japanese one. Many of our productions are characterized by the following:

1. Employees, especially if there are no incentives for them, do not seek to increase the profits of the enterprise. They are asking,why try to make the boss even richer if he already has everything.

2. The leaders themselves are not interested in the introduction of the "5S" system, because they do not see the expediency in it.

3. Many directives "down from above" are accustomed to carry out only for "tick". In Japan, there is a completely different attitude to their work. For example, the same Taiichi Ono, introducing the "5S" system, thought not about personal gain, but about the benefit of the company in which he was just an engineer.

4. At many enterprises, the 5S system is being forcibly introduced. Lean production, which implies the elimination of losses of all kinds (working time, raw materials, good employees, motivation and other indicators), does not work, as workers begin to resist innovations on a subconscious level, which ultimately reduces all efforts to zero.

5. Managers implementing the system do not fully understand its essence, which causes failures in established production processes.

6. Standardization often develops into bureaucracy, a good deed is overgrown with instructions and directives that only interfere with work.

Reviews

Russians who have introduced the "5S" system in production, the reviews about this innovation leave very mixed. Highlighted Pros:

- better to be in the workplace;

- do not distract from work with unnecessary little things;

- more clear workflow;

- fatigue decreased at the end of the shift;

- slightly increasedsalary by increasing labor productivity;

- occupational injuries decreased.

Noted cons:

- when sorting, they force everything to be thrown away;

- standardization has led to an increase in bureaucracy;

- The introduction of the "5C" system has not exacerbated the problems in all areas of the enterprise;

- Putting the 5S system in first place overshadowed important issues such as the lack of spare parts.

Recommended:

System "Rapida": description, features and reviews

The "Rapida" payment system is a universal service. Its services are suitable for both ordinary users and business owners. Consider the features of the platform and how the procedure for registering and identifying customers takes place

Basic principles of lending: description, features and requirements

In our difficult time, people are often plagued by financial problems. One of the best solutions in this situation is a loan. Find out what the principles of lending are and whether you meet the criteria for an exemplary borrower

Centralized management: system, structure and functions. Principles of the management model, pros and cons of the system

Which management model is better - centralized or decentralized? If someone in response points to one of them, he is poorly versed in management. Because there are no bad and good models in management. It all depends on the context and its competent analysis, which allows you to choose the best way to manage the company here and now. Centralized management is a great example of this

"Kanban", production system: description, essence, functions and reviews

Kanban is the most well-known industrial production management method within the Just-in-Time concept. With minimal organization costs, it can significantly reduce the time of work and the cost of material resources

Circulation system - description, installation features and reviews

The article is devoted to circulation systems. The device of this system is considered, as well as installation work on the installation of the pump and reviews