2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:47

Vises are universal devices designed to hold workpieces during manual (in this case, the vise is installed on a bench workbench) or mechanical (special machine vise is used) processing.

Manufacturers of machine tools offer a wide range of vices of various types. Each of the species has certain characteristics and has a number of features. Thus, based on the features of the technological process and the available equipment, we can conclude that the selection of a vice is a rather difficult task. How to make the right and optimal choice, taking into account the existing fleet of metalworking machines? The article provides an answer to this, as well as to other questions that may arise when organizing and purchasing equipment for your own workshop.

What materials are vices made of

Vise body is made of steel or gray cast iron. Cast iron cases are the most common. This is due to the fact that cast iron has very good casting qualities (the melt solidifies quitetakes a long time and manages to fill the entire mold) and is much cheaper than steel. At the same time, the mechanical properties of the alloy with a high content fully satisfy the requirements for materials used for the manufacture of both manual and machine vices.

The market is flooded with equipment from China, Europe and America. These countries have developed and use their own standards. As for the Russian Federation, the production of such equipment on its territory is strictly regulated by GOST 16518-96.

The most important technical characteristics of the vise

When choosing a specific device, you must carefully read its technical parameters and capabilities. First of all, in order not to throw money away, you need to find out what kind of machine equipment they are intended for installation on (milling, surface grinding, planing, broaching, drilling or other machines).

Then it is necessary to check whether the width of the working jaws is sufficient, or whether they are too narrow and will press hard on the surface of the workpiece, leaving dents in it. The clamping force is also important. The stroke length allows you to determine the maximum possible linear dimensions of the workpiece installed in the vise.

In the event that a vice is purchased for a small hobby machine installed in a garage or in the basement of an apartment building, or even on a balcony (there is such a thing!), Then the critical parameter, of course, is their weight. The weight limit of the product to be installed on a small hobby machine must not be exceeded, as the mechanical components of such a machine will quickly fail.

Types and varieties of vise for metalworking

- In accordance with the specified standard, the industry produces vices of normal accuracy, increased accuracy and high-precision, equipped with a manual or automatic (hydraulic, pneumatic, electric) drive.

- Depending on the purpose, the vise is divided into manual, bench, machine, special (with an automated drive).

- According to the type of drive, machine vices are distinguished with manual clamping, with hydraulic drive, with a cage (or eccentric clamp), with a spring clamp.

- Depending on the material being processed and its mechanical properties, jaws of different hardness and with different notches can be mounted on the vise.

Main elements of a vise

Modern machine vices are structurally significantly different from classic vices. However, the principle of operation and operation remained unchanged, and the following main components of the product can be distinguished: body, movable and fixed jaws, handle, power screw with trapezoidal thrust thread, handle.

Features of the vise mounted on the table of the milling machine

Machine milling vices are available, perhaps, at every workplace. And if, in conditions of mass production, they strive to make special devices for fixing workpieces on the worktable of the machine, then inconditions of single production, as well as repair production, not to mention the garage workshop, such a vise is simply an indispensable thing.

For machine tool vises, stiffness is the critical and most important parameter. If the design does not provide rigidity, then during processing, an unpleasant and irritating hearing of a person will occur, a loud screech of metal. In this case, the cutter will rattle. As a result, premature failure of a very expensive tool and unsatisfactory roughness of the machined surface. Sometimes a part may even go to waste, which means additional financial losses.

If the sponges on the universal locksmith vice have a characteristic corrugated surface, then on the vice for machine tools they should always be smooth. Moreover, a rough untreated smooth surface after casting is not allowed. Such sponges are processed with a cutting tool (milling cutter or cutter), and then ground on a surface grinder to achieve the desired roughness and geometric shape.

Rotary machine vise

Such a vise is mounted on a special rotary mechanism. It has no restrictions and can be rotated to any arbitrary angle. To make a turn, you need to unclench the two nuts at the base. After the desired angle is set, the nuts are tightened with a specific open-end wrench with as much force as possible.

The lack of suchvise is the lack of rigidity. But the pivot base can be removed, and then it will be a regular jig.

Machine vise for drilling machines

Vise mounted on the frame of vertical drilling machines should provide the possibility of shifting the workpiece in two directions in the horizontal plane. This statement is not true for radial drilling machines, since the spindle itself moves on them with a drill installed in it. In general, machine vices for drilling units have much less rigidity compared to milling vices, since they have many degrees of freedom.

Recommended:

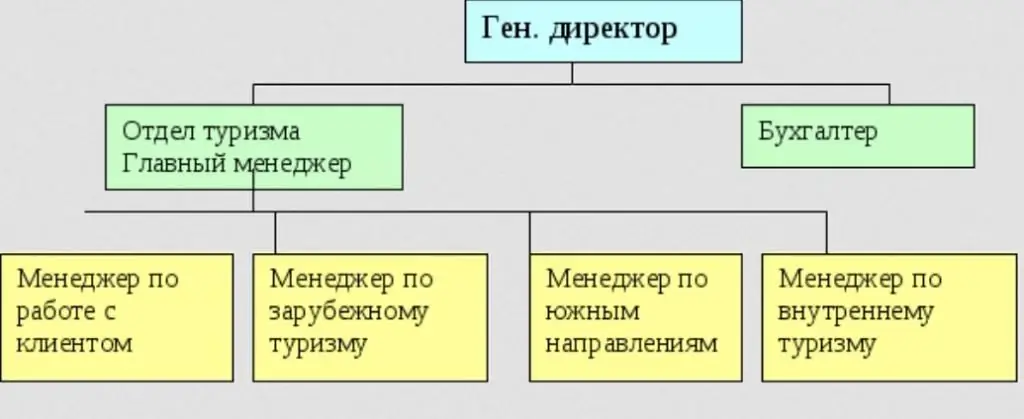

Types of tour operators and their characteristics. Functions and features of the activities of tour operators

The tour operator provides a wide range of travel services and simplifies the reservation of services in other cities and countries, taking on these tasks. In the field of tourism services, it occupies a special niche. In the article we will consider the types of activities of tour operators

Steel support: types, types, characteristics, purpose, installation rules, operation features and applications

Steel poles today are most often used as lighting poles. With their help, they equip the lighting of roads, streets, courtyards of residential buildings, etc. In addition, such structures are often used as supports for power lines

Two-component polyurethane sealant: definition, creation, types and types, characteristics, properties and nuances of application

With long-term and high-quality sealing of seams and cracks, polyurethane two-component sealants have found their wide distribution. They have high deformation and elastic properties, therefore, they can be used as butt sealants in the field of repair and housing construction

How to convert rubles into hryvnias? Features of the exchange of Russian money for Ukrainian and vice versa

The article describes the main methods of exchanging rubles for Ukrainian hryvnias. In addition, quick ways to find out the current exchange rate are listed. The article will be useful for those who need to exchange hryvnia for Russian currency

Chainsaw chain sharpening machine - overview, features, types and reviews

Intensive work with chain saws inevitably leads to the loss of working qualities of cutting equipment. With a conventional tool, only experienced craftsmen with proper dexterity can restore the geometry and the former sharpness of the saw segments