2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Steel poles are used to illuminate roads, streets, squares, parking lots, etc. Most often, the main material for the production of such things is galvanized metal. The height of these lighting poles varies from 3 meters to 12 meters. The main material for assembly is a bent type profile. There are hollow types of such poles, which allows you to bring power cables underground.

Main types of supports

There are non-power lighting poles that do not allow hanging SIP. For such supports, the maximum weight of the equipment placed on the pole cannot exceed 70 kg. Steel supports may have a different shape of the trunk. On this basis, three different types of pillars are distinguished:

- tubular;

- faceted;

- round-conical.

As for the first type, that is, tubular supports, they are mainly used only for decorative lighting of recreation areas, park areas. With regard to the design of such steel poles, they usually consist of several connected segments, and the maximum height is usually notexceeds 5 meters. The main method for mounting lighting fixtures is a floor lamp.

Other types of supports

Another kind of steel supports - faceted. The main purpose is the installation on the streets and sidewalks for their illumination. The method of manufacturing such structures is the pressing of steel sheets with a thickness of 2 to 4 mm into a conical shape of a column. The finished structure is seam welded. The maximum height for such structures is 16 meters, but their weight is not too large. For example, such a construction model as OGK-4 has a height of 4 meters. At the same time, its maximum weight is 34 kg. To date, technology allows you to create a special type of faceted structures, which is called folding. Such steel lighting poles have the ability to lower the lighting fixture.

The last type is round-conical supports. The maximum height of such poles is 10 meters, and they are used mainly for lighting public places. Steel sheet is used as the main material for production, the thickness of which should not exceed 4 mm. Such poles are capable of carrying up to 4 lamps.

Key Design Benefits

Such supports have a number of advantages, which have led to their widespread use.

- Easy design. The weight of the largest supports is only 145-150 kg. It seems that this is quite a lot, but given that suchpoles can be power lines, then it is small enough. In addition, there is a flange type that does not have a mortgage element; these weigh only 30-40 kg. They also have racks that are compact enough to carry up to 50 sets of trucks at a time.

- Strength. As for this parameter, due to the fact that sheet steel is used as the main element for production, the supports have a huge margin of safety and wind resistance. The column is able to withstand mechanical loads from 300 to 2000 kg, as well as wind loads up to 40 m/s. These characteristics are suitable for medium poles up to 10 meters high.

- It is possible to change the design of such a lighting pole.

- Service life. With regard to this characteristic, this is a huge advantage, since taking into account the anti-corrosion coating up to 80 microns and the large thickness of the metal, the support can serve from 50 to 75 years.

Installation work

As for the installation of steel supports, the process is quite simple. Non-power lighting poles are usually mounted either on a pre-prepared foundation, or simply concreted into the ground. In order to carry out this operation, it is necessary to carry out the process of installing an embedded element with holes for anchor bolts, for a steel anchor support. As for the parameters of the foundation, they change significantly depending on what kind of wind load the area is characterized by and what typesoil. If a mortgage element is dug in, then its length is from 1 to 3 meters. If the pillar itself is dug in directly, then the length can be up to 3 meters. It depends on the total length of the mounted column.

As for the fixtures, they are attached with brackets. They, in turn, are bolted to the post.

VL type supports

Today, there are such types of poles as steel poles of 35 kV overhead lines. Their main purpose is to conduct steel-aluminum cables through the air. As lighting poles, they are not used at all. As for their shape, in longitudinal section they have a regular polyhedral shape. For this reason, they are quite often referred to as steel polyhedral poles.

These bases are classified as free-standing. For their installation, it is necessary to drill a recess up to 3 meters long. Although there is also a flange mounting option. As for the assembly of the racks themselves, they are assembled using a telescopic joint.

Types of supports

Today, there is also a division of such poles into several types, namely 4. This includes such types as power, non-power, decorative, high-mast.

As for the first type, they got their name due to the fact that a cable can be brought to them by air, if there is no possibility of laying underground. Here you can also install lamps of varioustype, if you carry out the installation of brackets.

The second type is non-power bearings that are used for street lighting. The main difference from the previous type is that such poles cannot be used for laying overhead lines. Their functionality is limited to hanging lamps at a height of up to 12 meters. This also includes folding and decorative supports.

Next are fully decorative models. Naturally, their main difference lies in their appearance, which is much better than other types. In addition, you can use a variety of types of fixtures themselves for connection. Most often they are installed in places of public recreation, on embankments or near cultural attractions. Most often, their height is small and is only 3-4 meters. However, rare specimens can be as high as 12 meters if they need to be installed near multi-storey cultural buildings.

The last type belongs to a more specialized class, as it is used for lighting airports, stadiums and other things. They are quite different in size, crown and many other characteristics. The crown can be fixed or movable. The stationary crown is more difficult to maintain, since you have to climb to it at a great height. Mobile, on the contrary, goes down, which makes this process easier.

Types of supports by design

Today, steel poles are usually made of longitudinally welded or seamless pipes or steelroll type. As for the method of their installation, they are flanged or straight-rack. The second option is the simplest structures to install, which are installed in a pre-prepared recess, after which they are poured with concrete. Flanged are divided into two parts - underground and aboveground. The installation process consists in the fact that you must first install the underground part and concrete it. The upper part of the support is bolted.

Steel movable supports

The difference between this pole and the rest is that it is used not for lighting, but in the heating system. Movable structures are used in the heating network to support the heat pipeline, as well as to ensure its free movement. They are quite widespread, since they can be installed with almost all types of laying the pipes themselves. The only exception is the channelless method. In this case, the heat pipeline is laid on a large layer of sand, which ensures a fairly good transfer of weight loads to the ground.

Recommended:

Food stainless steel: GOST. How to identify food grade stainless steel? What is the difference between food stainless steel and technical stainless steel?

The article talks about grades of food grade stainless steel. Read how to distinguish food stainless steel from technical

Machines for furniture production: types, classification, manufacturer, characteristics, instructions for use, specification, installation and operation features

Modern equipment and machines for furniture manufacturing are software and hardware tools for processing blanks and fittings. With the help of such units, craftsmen perform cutting, edging and adding parts from MDF, chipboard, furniture board or plywood

Electric locomotive 2ES6: history of creation, description with photo, main characteristics, principle of operation, features of operation and repair

Today, communication between different cities, passenger transportation, delivery of goods is carried out in a variety of ways. One of these ways was the railroad. Electric locomotive 2ES6 is one of the types of transport that is currently actively used

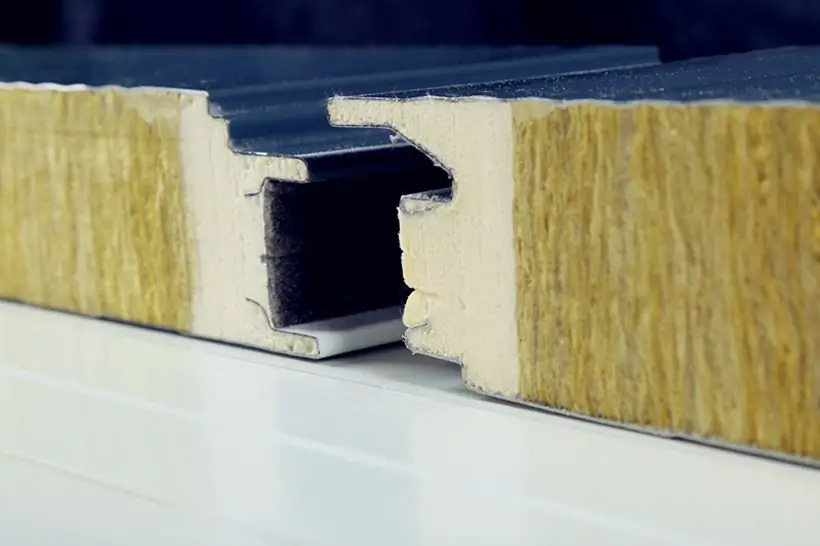

Thermal conductivity of sandwich panels: concept, main characteristics, dimensions, thickness, thermal conductivity coefficient, installation rules, pros and cons of operation

Thermal conductivity of sandwich panels will be the lowest if polyurethane foam is the basis. The parameter under consideration here varies from 0.019 to 0.25. The material is strong, dense and light. It is chemically resistant and does not absorb moisture. Rodents are indifferent to polyurethane foam, fungi and mold do not develop inside it. Working temperature reaches +160 ˚С

Protection devices: purpose, types, classification, specifications, installation, features of operation, settings and repair

Protection devices are currently in operation almost everywhere. They are designed to protect both electrical networks and electrical equipment, various machines, etc. It is very important to properly install and follow the operating rules so that the devices themselves do not cause a fire, explosion, etc