2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:49

Everyone wants to live in comfort and peace. If the owners of private houses set such a goal, then they try to protect the home from extraneous noise and cold with the help of special materials. If you are looking for protection from the winter cold and summer heat, you can use mineral wool insulation. This material is presented for sale in several varieties, each of which has its pros and cons, so you need to study them before making a purchase.

Thermal conductivity

The thermal conductivity of mineral wool reaches 0.040 W/m°C and depends on the density. Thermal insulation can be based on different raw materials, which affects the fiber structure. On sale you can find horizontally and vertically layered, spatial or corrugated-layered wool, which greatly expands the possibilities of using the material in various designs.

The thermal conductivity of mineral wool will not always remain the same. This parameter increases by 50% in 3 years, which is due to the penetration of moisture into the structure. It is important, in conjunction with this characteristic, to pay attention also to the vapor permeability, which is equal to one if there is no vapor barrier. The mentioned properties act as one of the main characteristics that affect the area of use of the material.

Thermal conductivity of mineral wool varieties

Thermal conductivity is the process of transferring heat from a heater to a material with a lower temperature. The described thermal insulation includes the following types of cotton wool:

- glass;

- slag;

- stone;

- bas alt.

Each of these species has its own coefficient of thermal conductivity. As for glass wool, the mentioned parameter can be equal to a maximum of 0.052 W / mK. For bas alt wool, this characteristic can vary from 0.035 to 0.046 W / mK. If we are talking about slag wool, then the mentioned property is equal to the limit of 0.46-0.48 W / mK. The thickness of the insulation affects the quality of thermal insulation and thermal conductivity. The value of thermal conductivity is prescribed in state standards GOST 7076-994.

Comparison of Thermal Conductivity of Isover Mineral Wool

Before purchasing this or that material, you mustFamiliarize yourself with the parameters of thermal conductivity of mineral wool. The comparison can be made using Isover branded thermal insulation as a basis. If it is represented by a roll and is labeled "Classic", then the thermal conductivity coefficient will be equal to the limit of 0.033-0.037 W / mK. This insulation is used for structures where the layer will be subjected to loads.

When purchasing Karkas-P32 mineral wool, you will use plates with a thermal conductivity coefficient within 0.032-0.037 W/mK. This wool is used for thermal insulation of frame structures. Mats "Karkas-M37" have a coefficient of thermal conductivity, which is equal to 0.043 W / mK maximum. This material is also used for frame structures, like "Karkas-M40-AL" with a thermal conductivity coefficient of 0.046 W/mK and no more.

All of the above insulations have a low coefficient of thermal conductivity, which provides excellent sound and heat protection. The structure of the fiber plays an important role in this matter. To insulate the frame walls, mineral wool "Karkas-P32" is used, which has a thermal conductivity coefficient of 0.032 W/mK, which is the lowest.

Coefficient of thermal conductivity of Ursa cotton wool

The table of thermal conductivity and other qualities of the material quite often allows consumers to make the right choice. This is also true when it comes to Ursa mineral wool. If you need insulation for thermal insulationroofs, floors and walls, then you can choose "Ursa Geo M-11" with a coefficient of thermal conductivity within 0.040 W / mK. Slabs, presented in rolls and produced under the name URSA GEO, are designed for pitched roofs. The thermal conductivity coefficient in this case is 0.035 W/mK.

For insulation of floors, acoustic ceilings and ceilings, URSA GEO Light rolls are used, in which the described characteristic is equal to the limit of 0.044 W / mK. As practice shows, the properties of mineral wool insulation under the Ursa brand are among the best. With the help of this insulation, you can reliably insulate the house, as a result, it is possible to achieve the formation of a breathable surface with air gaps. Using a unique recipe and environmentally friendly technology, Ursa Geo is produced, which deserves special attention.

Thermal conductivity of Rockwool mineral wool

The thermal conductivity of Rockwool mineral wool may also be of interest to you. This material is offered for sale in several items, each of which is represented by slabs or mats. For example, Rockmin with a coefficient in the range of 0.039 W / mK is available in the form of plates and is intended for sound and heat insulation of attics, walls, roofs and ventilated coverings.

Domrock mats can be used for suspended ceilings, beamed ceilings and lightweight stud walls. The described characteristic in this case is 0.045 W / mK. Panelrock is offered for sale in the form of slabs andDesigned for sound and heat insulation of external walls. The thermal conductivity coefficient of this material is 0.036 W/mK.

If you have a Monrock max slab in front of you, then you can purchase it for insulating various types of flat roofs. The thermal conductivity coefficient in the case of this thermal insulation solution is 0.039 W/mK. You may also be interested in the thermal conductivity coefficient of Stroprock mineral wool from Rockwool. It is equal to 0.041 W / mK, and the material can be used for sound and heat insulation of floors and ceilings, the first of which are arranged on the ground, while others are located under a concrete screed. Mineral wool in the form of Alfarock mats, which is used to insulate pipelines and pipes, should be placed in a special section. The thermal conductivity coefficient in this case is 0.037 W/mK.

Features of TechnoNIKOL mineral wool

If you decide to choose TechnoNIKOL products, the thermal conductivity of mineral wool from this manufacturer should also interest you. It is equal to the limit from 0.038 to 0.042 W/mK. The material is hydrophobized non-combustible boards, which are designed for sound and heat insulation. A material is created on the basis of rocks that belong to the bas alt group.

Slabs are used in industrial and civil construction, external wall insulation systems, where the material is protected from above by a decorative coating of thin-layer plaster. The material is not combustiblevapor permeability is 0.3 Mg/(m·h·Pa). Water absorption is 1% by volume. The density of the material can be equal to the limit from 125 to 137 kg/m3.

The thermal conductivity of mineral wool is not the only property to be aware of. It is important to take an interest in other parameters, for example, length, width and thickness. The first two are 1200 and 600 mm, respectively. As for the length, in increments of 10 mm it can vary from 40 to 150 mm.

Basic Features

Mineral wool is resistant to chemicals and high temperatures. It has excellent sound and heat insulation properties. The material is used not only in construction, where it is required to insulate floors and walls, but also for insulating high-temperature surfaces such as pipelines and furnaces. The material can become a fire protection of structures and act as a protective layer in acoustic screens and partitions. In stone wool products, which are made on a synthetic binder, the process of destruction begins when the temperature of exposure to the material is equal to the limit of 300 °C.

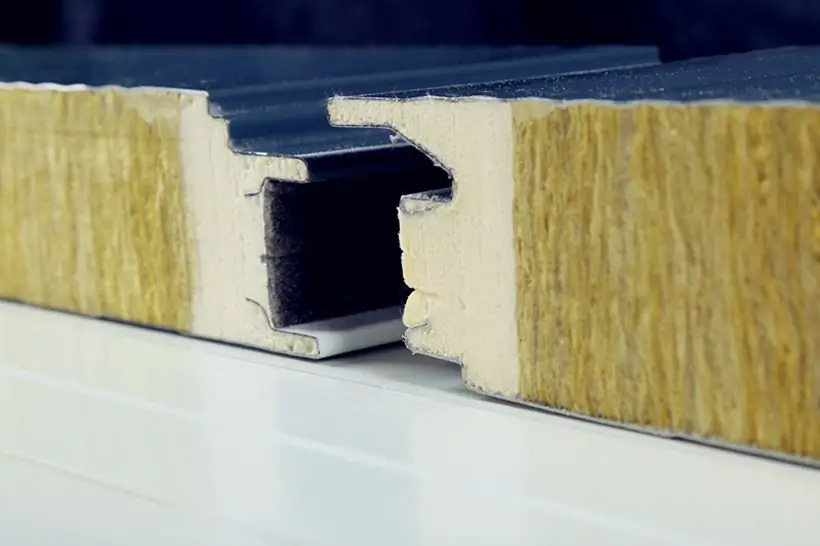

Properties of mineral wool sandwich panels

In construction, mineral wool sandwich panels are quite popular. The thermal conductivity coefficient of this material is equal to the limit from 0.20 to 0.82 W/mK. The degree of sound insulation of the material is 24 dB. The shear strength is 100 kPa, as is the compressive strength. The density of products can be equal to the limit from 105 to 125kg/m3.

The structures do not require the use of special equipment for construction work, they are easily exposed to ultraviolet radiation, as well as temperature changes. Sandwich panels are not susceptible to rust, they are resistant to fire and have excellent heat and sound insulation qualities. If the panels are damaged, they can be partially replaced. Such structures do not create an extra load on the foundation. Visiting the store, you can choose any shade of panels, which allows you to achieve an excellent aesthetic result.

Conclusion

Mineral wool is offered for sale under different labels that define properties and areas of use. For example, P-75 has the density mentioned in the title. The material is excellent for thermal insulation of horizontal planes, which will not experience heavy loads during operation. If you need a material for insulating a ceiling or floor, then you can prefer P-125, the density of which is mentioned in the marking. This material proved to be excellent for insulating partitions and walls used indoors.

Recommended:

Thermal imaging control of electrical equipment: concept, principle of operation, types and classification of thermal imagers, features of application and verification

Thermal imaging control of electrical equipment is an effective way to identify defects in power equipment that are detected without shutting down the electrical installation. In places of poor contact, the temperature rises, which is the basis of the methodology

Thermal conductivity of concrete: features, coefficient and table

The thermal conductivity of concrete is determined by special formulas. For different types of material, this indicator may be different. Lightweight concrete retains heat better, heavy concrete worse

Mineral wool density: classification, advantages and disadvantages, purpose of mineral wool and application

Mineral wool is the most popular type of insulation for an apartment or house. Today it is used by everyone, from builders to the owner of the apartment, who wanted to insulate the room. The simplicity of its installation allows you to immediately insulate the entire house (ceiling, walls, floor). We will study the features and characteristics of the named material further in the article

Thermal conductivity of sandwich panels: concept, main characteristics, dimensions, thickness, thermal conductivity coefficient, installation rules, pros and cons of operation

Thermal conductivity of sandwich panels will be the lowest if polyurethane foam is the basis. The parameter under consideration here varies from 0.019 to 0.25. The material is strong, dense and light. It is chemically resistant and does not absorb moisture. Rodents are indifferent to polyurethane foam, fungi and mold do not develop inside it. Working temperature reaches +160 ˚С

Expanded clay: thermal conductivity, properties and technical characteristics

Expanded clay is made from slate and clay and is suitable for environmentally friendly and modern housing construction. Expanded clay is also used for decorative purposes, and at home it is suitable for solving the problems of growing cultivated plants