2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

One of the most important characteristics of concrete, of course, is its thermal conductivity. This indicator can vary significantly for different types of material. The thermal conductivity of concrete depends primarily on the type of filler used in it. The lighter the material, the better the insulator from the cold.

What is thermal conductivity: definition

Different materials can be used in the construction of buildings and structures. Residential and industrial buildings in the Russian climate are usually insulated. That is, during their construction, special insulators are used, the main purpose of which is to maintain a comfortable temperature inside the premises. When calculating the required amount of mineral wool or polystyrene foam, the thermal conductivity of the base material used for the construction of the enclosing structures is taken into account.

Very often, buildings and structures in our country are built from different types of concrete. Brick and wood are also used for this purpose. Actually, thermal conductivity itself is the ability of a substance to transfer energy in its thickness due to the movement of molecules. Goa similar process can, both in the solid parts of the material, and in its pores. In the first case, it is called conduction, in the second - convection. The cooling of the material is much faster in its solid parts. Air filling the pores traps heat, of course better.

What determines the indicator

Conclusions from the above can be drawn as follows. The thermal conductivity of concrete, wood and brick, like any other material, depends on them:

- density;

- porosity;

- humidity.

With the increase in the density of concrete, the degree of its thermal conductivity also increases. The more pores in the material, the better insulator from the cold it is.

Types of concrete

In modern construction, a variety of types of this material can be used. However, all concretes existing on the market can be classified into two large groups:

- heavy;

- light foamy or with porous filler.

Thermal conductivity of heavy concrete: indicators

Such materials are also divided into two main groups. Concrete can be used in construction:

- heavy;

- especially heavy.

In the production of the second type of material, fillers such as metal scrap, hematite, magnetite, barite are used. Especially heavy concretes are usually used only in the construction of facilities whose main purpose is protection from radiation. This group includes materials with a density from 2500 kg/m3.

Ordinary heavy concrete is made using such types of filler as granite, diabase or limestone, made on the basis of crushed stone. In the construction of buildings and structures, a similar material with a density of 1600-2500 kg/m is used3.

What can be the thermal conductivity of concrete in this case? The table below shows the performance of different types of heavy material.

| Type of concrete | Extremely heavy | Heavy for RC structures | On the sand |

| Thermal conductivity W/(m°C) | 1, 28-1, 74 | At density 2500kg/m3 - 1.7 | At density 1800-2500 kg/m3 - 0.7 |

Thermal conductivity of lightweight cellular concrete

This material is also classified into two main varieties. Very often, concretes based on porous filler are used in construction. As the latter, expanded clay, tuff, slag, pumice are used. In the second group of lightweight concretes, a regular filler is used. But in the process of kneading, such material foams. As a result, after maturation, it remains a lot of pores.

The thermal conductivity of lightweight concrete is very low. But at the same time, in terms of strength characteristics, such a material is inferior to a heavy one. Lightweight concrete is used most often for the construction of various kinds of residential andoutbuildings that are not subject to serious loads.

Lightweight concretes are classified not only by the method of manufacture, but also by purpose. In this regard, there are materials:

- heat-insulating (with density up to 800 kg/m3);

- structural and heat-insulating (up to 1400 kg/m3);

- structural (up to 1800 kg/m3).

Thermal conductivity of cellular lightweight concrete of different types is presented in the table.

| Type of concrete | Heat-insulating | Structural and thermal insulation | Constructional |

| Maximum allowable thermal conductivity W/(m°C) | 0, 29 | 0, 64 | Not standardized |

Heat insulation materials

Such concrete blocks are usually used for lining walls assembled from bricks or poured from cement mortar. As can be seen from the table, the thermal conductivity of concrete of this group can vary over a fairly large range.

| Material | Aerated concrete | Expanded concrete |

| Thermal conductivity W/(m°C) | 0, 12-0, 14 | 0, 23-0, 4 |

Concrete of this variety is most often usedas insulating materials. But sometimes various kinds of insignificant building envelopes are erected from them.

Structural, heat-insulating and structural materials

From this group, foam concrete, slag-pumice concrete, slag concrete are most often used in construction. Some types of expanded clay concrete with a density over 0.29 W / (m ° C) can also be attributed to this variety.

| Material | Aerated concrete | Slag pumice concrete | Slag concrete |

| Thermal conductivity | 0.3W/(m°C) | Up to 0.63 W/(m°C) | 0.6W/(m°C) |

Very often such concrete with low thermal conductivity is used directly as a building material. But sometimes it is also used as an insulator that does not let the cold through.

How does thermal conductivity depend on humidity

Everyone knows that almost any dry material insulates from the cold much better than wet. This is primarily due to the very low degree of thermal conductivity of water. They protect concrete walls, floors and ceilings from low outdoor temperatures, as we found out, mainly due to the presence of air-filled pores in the material. When wet, the latter is displaced by water. And, consequently, the coefficient of thermal conductivity of concrete increases significantly. In the cold season, caught in the poresmaterial water freezes. The result is that the heat-retaining qualities of walls, floors and ceilings are further reduced.

The degree of moisture permeability of different types of concrete may vary. According to this indicator, the material is classified into several grades.

| Concrete grade | W4 | W6 | W8 | W10-W14 | W16-W20 |

| Water-cement ratio (no more) | 0, 6 | 0, 55 | 0, 45 | 0, 35 | 0, 30 |

Wood as an insulator

Both "cold" heavy and light concrete, the thermal conductivity of which is low, of course, are very popular and sought-after types of building materials. In any case, the foundations of most buildings and structures are built from cement mortar mixed with crushed stone or rubble stone.

Concrete mixture or blocks made from it are also used for the construction of building envelopes. But quite often, other materials are used to assemble the floor, ceilings and walls, for example, wood. Timber and board differ, of course, much less strength than concrete. However, the degree of thermal conductivity of wood, of course, is much lower. For concrete, this indicator, as we found out, is 0.12-1.74 W / (m ° C). In a tree, the coefficient of thermal conductivity depends, includingincluding and from this particular breed.

| Type of wood | Pine | Linden, fir | Spruce | Poplar, oak, maple |

| Thermal conductivity W/(m°C) | 0, 1 | 0, 15 | 0, 11 | 0, 17-0, 2 |

In other breeds, this figure may be different. It is believed that the average thermal conductivity of wood across the fibers is 0.14 W / (m ° C). The best way to insulate space from the cold is cedar. Its thermal conductivity is only 0.095 W/(m C).

Brick as an insulator

Next, for comparison, consider the characteristics in terms of thermal conductivity and this popular building material. In terms of strength properties, brick is not only not inferior to concrete, but often surpasses it. The same applies to the density of this building stone. All bricks used today in the construction of buildings and structures are classified into ceramic and silicate.

Both of these types of stone, in turn, can be:

- corpulent;

- with voids;

- slotted.

Of course, solid bricks retain heat worse than hollow and slotted ones.

| Brick | Full-bodied silicate/ceramic | Silicate/ceramic with voids | Slotted silicate/ceramic |

| Thermal conductivity W/(m°C) | 0, 7-0, 8/0, 5-0, 8 | 0, 66 /0, 57 | 0, 4/0, 34-0, 43 |

The thermal conductivity of concrete and brick is thus almost the same. Both silicate and ceramic stone insulate rooms from the cold rather weakly. Therefore, houses built from such material should be additionally insulated. As insulators when sheathing brick walls, as well as those poured from ordinary heavy concrete, expanded polystyrene or mineral wool is most often used. You can also use porous blocks for this purpose.

How thermal conductivity is calculated

This indicator is determined for different materials, including concrete, according to special formulas. In total, two methods can be used. The thermal conductivity of concrete is determined by the Kaufman formula. It looks like this:

0.0935x(m) 0.5x2.28m + 0.025, where m is the mass of the solution.

For wet (more than 3%) solutions, the Nekrasov formula is used: (0.196 + 0.22 m2) 0.5 - 0.14.

Expanded concrete with a density of 1000 kg/m3 has a mass of 1 kg. Accordingly, for example, according to Kaufman, in this case, a coefficient of 0.238 will be obtained. The thermal conductivity of concrete is determined at a mixture temperature of +25 C. For cold and heated materials, itsfigures may vary slightly.

Recommended:

Thermal imaging control of electrical equipment: concept, principle of operation, types and classification of thermal imagers, features of application and verification

Thermal imaging control of electrical equipment is an effective way to identify defects in power equipment that are detected without shutting down the electrical installation. In places of poor contact, the temperature rises, which is the basis of the methodology

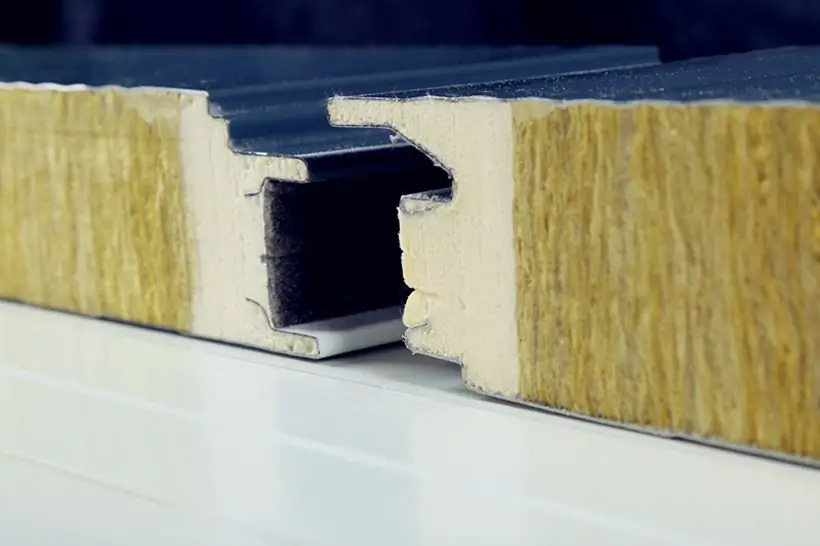

Thermal conductivity of sandwich panels: concept, main characteristics, dimensions, thickness, thermal conductivity coefficient, installation rules, pros and cons of operation

Thermal conductivity of sandwich panels will be the lowest if polyurethane foam is the basis. The parameter under consideration here varies from 0.019 to 0.25. The material is strong, dense and light. It is chemically resistant and does not absorb moisture. Rodents are indifferent to polyurethane foam, fungi and mold do not develop inside it. Working temperature reaches +160 ˚С

Mobility of concrete: types, table, GOST and features

Currently, one of the most common building materials is concrete mix. With the help of this raw material, many objects are built. It has many different parameters and characteristics, among which there is one called the mobility of concrete

Expanded clay: thermal conductivity, properties and technical characteristics

Expanded clay is made from slate and clay and is suitable for environmentally friendly and modern housing construction. Expanded clay is also used for decorative purposes, and at home it is suitable for solving the problems of growing cultivated plants

Thermal conductivity of mineral wool: properties and features

If you are looking for protection from the winter cold and summer heat, you can use mineral wool insulation. This material is presented for sale in several varieties, each of which has its pros and cons, so you need to study them before making a purchase