2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:25

Anodizing is an electrolytic process that is used to increase the thickness of the layer of natural oxides on the surface of products. This technology got its name due to the fact that the processed material is used as an anode in the electrolyte. As a result of this operation, the resistance of the material to corrosion and wear is increased, and the surface is also prepared for the application of primer and paint.

Applying additional protective layers after metal anodizing is carried out much better than the original material. The anodized coating itself, depending on the method of its application, can be porous, absorbing dyes well, or thin and transparent, emphasizing the structure of the original material and reflecting light well. The formed protective film is a dielectric, that is, it does not conduct electric current.

Why is this done

Anodized finish used where requiredprovide protection against corrosion and avoid increased wear in the contacting parts of mechanisms and devices. Among other methods of surface protection of metals, this technology is one of the cheapest and most reliable. The most common use of anodizing is to protect aluminum and its alloys. As you know, this metal, having such unique properties as a combination of lightness and strength, has an increased susceptibility to corrosion. This technology has also been developed for a number of other non-ferrous metals: titanium, magnesium, zinc, zirconium and tantalum.

Some Features

The process under study, in addition to changing the microscopic texture on the surface, also changes the crystal structure of the metal at the border with the protective film. However, with a large thickness of the anodized coating, the protective layer itself, as a rule, has a significant porosity. Therefore, in order to achieve corrosion resistance of the material, its additional sealing is required. At the same time, a thick layer provides increased wear resistance, much more than paints or other coatings, such as spraying. As the surface strength increases, it becomes more brittle, that is, more susceptible to cracking from thermal, chemical, and impact cracking. Cracks in the anodized coating during stamping are by no means a rare occurrence, and the developed recommendations do not always help here.

Invention

First documentedthe recorded use of anodizing occurred in 1923 in England to protect seaplane parts from corrosion. Initially, chromic acid was used. Later, oxalic acid was used in Japan, but today, in most cases, classical sulfuric acid is used to create an anodized coating in the composition of the electrolyte, which significantly reduces the cost of the process. Technology is constantly being improved and developed.

Aluminum

Anodized to improve corrosion resistance and prepare for painting. And also, depending on the technology used - either to increase the roughness, or to create a smooth surface. At the same time, anodizing in itself is not capable of significantly increasing the strength of products made from this metal. When aluminum comes into contact with air or any other gas containing oxygen, the metal naturally forms an oxide layer 2-3 nm thick on its surface, and on alloys its value reaches 5-15 nm.

The thickness of the anodized aluminum coating is 15-20 microns, that is, the difference is two orders of magnitude (1 micron is equal to 1000 nm). At the same time, this created layer is distributed in equal proportions, relatively speaking, inside and outside the surface, that is, it increases the thickness of the part by ½ of the size of the protective layer. Although anodizing produces a dense and uniform coating, the microscopic cracks present in it can lead to corrosion. In addition, the surface protective layer itself is subject to chemical decomposition.due to exposure to an environment with high acidity. To combat this phenomenon, technologies are used that reduce the number of microcracks and introduce more stable chemical elements into the oxide composition.

Application

Machined materials are widely used. For example, in aviation, many structural elements contain aluminum alloys under study, the same situation is in shipbuilding. The dielectric properties of the anodized coating predetermined its use in electrical products. Products made from processed material can be found in various household appliances, including players, lights, cameras, smartphones. In everyday life, an anodized iron coating is used, more precisely, its soles, which significantly improves its consumer properties. When cooking, special Teflon coatings can be used to avoid burning food. Usually such kitchen utensils are quite expensive. However, a non-anodized aluminum frying pan is able to provide a solution to the same problem. At the same time, at a lower cost. In construction, anodized coating of profiles is used for mounting windows and other needs. In addition, colorful details attract the attention of designers and artists, they are used in various cultural and art objects around the world, as well as in the manufacture of jewelry.

Technology

Special electroplating shops andindustries that are considered "dirty" and harmful to human he alth. Therefore, recommendations for the process at home, advertised in some sources, should be taken with extreme caution, despite the seeming simplicity of the described technologies.

Anodized coating can be created in several ways, but the general principle and sequence of work remains classic. At the same time, the strength and mechanical properties of the material obtained depend on, in fact, the source metal itself, on the characteristics of the cathode, the current strength and the composition of the electrolyte used. It should be emphasized that as a result of the procedure, no additional substances are applied to the surface, and the protective layer is formed by transforming the source material itself. The essence of electroplating is the effect of electric current on chemical reactions. The whole process is divided into three main stages.

First stage - preparation

At this stage, the product is thoroughly cleaned. The surface is degreased and polished. Then there is the so-called etching. It is carried out by placing the product in an alkaline solution, followed by moving it into an acidic solution. These procedures are completed by flushing, during which it is extremely important to remove all chemical residues, including hard-to-reach areas. The final result largely depends on the quality of the first stage.

Second stage - electrochemistry

At this stage, the anodized aluminum coating is actually created. Carefully prepared workpiecehung on brackets and lowered into a bath with electrolyte, placed between two cathodes. For aluminum and its alloys, cathodes made of lead are used. Usually the composition of the electrolyte includes sulfuric acid, but other acids can be used, for example, oxalic, chromic, depending on the future purpose of the machined part. Oxalic acid is used to create insulating coatings of different colors, chromic acid is used to process parts that have a complex geometric shape with small diameter holes.

The time required to create a protective coating depends on the temperature of the electrolyte and on the strength of the current. The higher the temperature and the lower the current, the faster the process. However, in this case, the surface film is quite porous and soft. To obtain a hard and dense surface, low temperatures and high current density are required. For sulfate electrolyte, the temperature range is from 0 to 50 degrees, and the specific current strength is from 1 to 3 amperes per square decimeter. All parameters for this procedure have been worked out over the years and are contained in the relevant instructions and standards.

Third stage - consolidation

After the electrolysis is completed, the anodized product is fixed, that is, the pores in the protective film are closed. This can be done by placing the treated surface in water or in a special solution. Before this stage, an effective painting of the part is possible, since the presence of pores will allow good absorption.dye.

Development of anodizing technology

To obtain a heavy-duty oxide film on the surface of aluminum, a method was developed to use a complex composition of various electrolytes in a certain proportion, combined with a gradual increase in electric current density. A kind of "cocktail" of sulfuric, tartaric, oxalic, citric and boric acids is used, and the current strength in the process gradually increases five times. Due to this effect, the structure of the porous cell of the protective oxide layer changes.

Special mention should be made of the technology of changing the color of an anodized object, which can be done in different ways. The simplest is to place the part in a solution with hot dye immediately after the anodizing procedure, that is, before the third stage of the process. The process of coloring with the use of additives directly into the electrolyte is somewhat more complicated. Additives are usually s alts of various metals or organic acids, allowing you to get the most diverse range of colors - from absolutely black to almost any color from the palette.

Recommended:

1/300 refinancing rate. Where and how is it applied

Contractual relations between counterparties include the condition of compensation for pen alties and fines using the requirements of Article 395 of the Civil Code of the Russian Federation. When a person sees the word "pen alty" in a utility bill or in the text of a loan agreement, he has a desire to figure out if it's a lot - 1/300 of the refinancing rate

Tender - what is it? The meaning of the word and how it is applied in practice

Today, almost all products on the market are purchased on a tender basis. A tender is, in fact, a competition, according to the results of which the Customer company selects a Supplier or Contractor who is ready to offer the most favorable conditions for cooperation: low price, original solutions or unsurpassed professionalism

What is milk made of? How is milk powder made?

Surely everyone is concerned about the question of what milk is made of. In this article we will try to find answers to it and learn a lot about this product familiar from childhood

Anodized aluminium. Special coating for material

Aluminum itself is a very light material that can be machined well. However, when interacting with oxygen, this substance oxidizes rather quickly, which is why it is impossible to use it for dishes, for example. However, anodized aluminum solved almost all problems

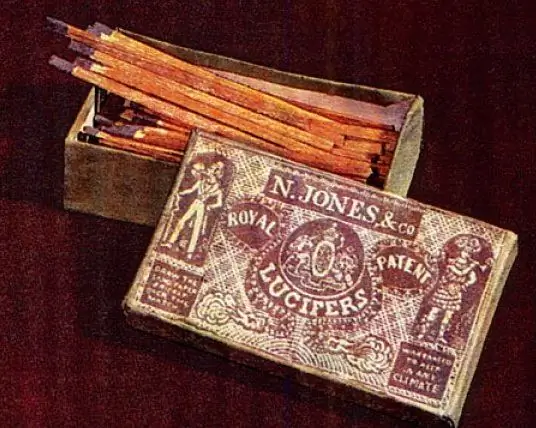

How were matches made before and how are they made today? Swedish matches

The article is devoted to the history of the creation of matches - from their very first prototypes to modern ones. It also tells about the famous Swedish matches, the evolution of the chemical components of the match head and stickers for the box