2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:25

Universal lathes are relatively small machines mainly for piece work. In simple models, to control the drives of the spindle and axes, complex automation is not required, everything is simplified to the maximum. Often the design uses a digital indication device to control the position of the axes.

Separate class of equipment

Universal lathes are purchased by small production sites, repair shops, hobbyists. The processing process can be visualized, as well as automatic control can be realized using a conventional low-power computer. Refinement instructions can be found on the Internet, all information is open.

More often they buy small universal lathes, the price of which starts from 1 million rubles, from Russian and Chinese manufacturers. If we take European equipment, then the cost can be about 10 million rubles, depending on the size and configuration. ATRussian customers prefer the brands of Taiwanese machine tool builders, which have an almost perfect price-quality ratio.

Universal lathes work close to complex machining centers where the machining process is fully automatic. But setting up a cycle without CNC is impossible without using a computer. However, when the cost of a modern CNC is comparable to half the cost of a machine, control from an old PC will be much more cost-effective. The necessary software is in the public domain, and working with it does not require additional investments, except for the cost of studying the manuals.

Universal lathes have high geometric accuracy. Can be installed on the foundation without anchors. Modern electronics make it possible to implement microfeeds for the axes, which expands the possibilities of processing parts.

What can be produced?

The wide use of machines is due to their versatility, namely the ability to process various surfaces with minimal equipment changeover time. An experienced craftsman is able to carve a part according to a drawing with laboratory precision.

Types of processing on a universal turning-milling machine are as follows:

- External turning, boring, end face machining.

- Universal lathes allow you to process parts by cutting. The technology is implemented thanks to the axial rotation of the workpiece and the translational movement of the tool.

- Drilling. If aSince there is a spindle positioning function and a milling head, the machine is able to produce parts with holes in any position of the workpiece.

- Milling of helical surfaces (with dividing head and rotary table). Threading external and internal.

- Processing by cold forming during rotation.

Design

The turret with a 12-station live tool greatly expands the capabilities of the equipment. The tool disk is made at the request of the customer for a larger number of positions, but this increases the cost of equipment. The turntable is an option, only available on more expensive models.

To process bars, a bar feeder (bar feeder) can be connected to the machines. The bar is automatically fed through the lathe spindle directly into the clamping device. To implement the technology, you will need a hollow spindle with the required hole and adapter bushings for each diameter of the workpiece (so that there is no bar chatter during rotation). Also, the machine must have a compatible interface for electrical connections.

The dividing head is a cheaper analogue of the spindle positioning. The latter option requires expensive CNC boards. The head is easy to mount for occasional multi-angle milling tasks (e.g. hexagonal surfaces).

Compact

Universala lathe with a DRO has a minimum of an electrical part, which is competently packed in a frame or in a separate wall cabinet. Efficient use of the working space, where it is easy to fit: a small turret, tailstock and spindle chuck. The axes are limited in coordinates by software and emergency limit switches.

The compact arrangement of working units allows the use of machines in the medical industry (dentistry). All mechanical components are standardized. It is possible to reconfigure the equipment for any production task. On many models, a milling spindle (milling head) can be easily installed in the place where the chuck is installed. Or, instead of the tailstock, mount a counter spindle.

Spindle

In all lathes, the main unit is the spindle. According to its power, the supply power is calculated. Can be hollow or plain depending on production needs.

In universal machines, a manual gearbox (which is a set of gears with shift levers) is more often used.

Gearbox allows you to change:

- Frequency of rotation of the part (revolutions).

- Rotation force - moment.

The main geometric parameter of the spindle is runout, which on modern equipment is no more than 5 microns. For axial positioning of the spindle, an encoder (angle sensor) is used, as well as an electronic board,responsible for tracking the position sensor. The main motor can be asynchronous or synchronous.

Powerful spindles are equipped with a cooling system. If the latter is available, long-term processing of parts at maximum speed is allowed.

Key features for equipment selection

Before looking for a machine, you must have the technology requirements. Guided by the following criteria in the process of finding equipment:

- Dimensions - distance between centers (length of workpiece clamp), height from the bed plane to the axis of rotation of the spindle (height of centers), spindle bore diameter, lateral movement of the workpiece and tailstock (quill) travel length.

- Workpiece holding mass.

- The spindle torque is taken into account.

- Force along the axes.

- Spindle clamping pressure, counter spindle, tailstock.

- Machine weight.

- Maximum spindle speed.

- Types of spindle tapers, tailstock. Dimensions and type of tool to be installed.

Opinion of equipment users

Repair workshops, almost all industries, furniture factories, even private traders prefer to purchase universal lathes. The price of the simplest professional models starts from several hundred thousand rubles. Less functional units can be purchased cheaper, but this is not recommended due to the use of poor quality materials.

When using universal screw-cutting lathesthere is a performance increase of at least 2 times. And with such a cost of equipment, its purchase is the most profitable purchase.

What experienced users think about the machines:

- For example, workers respond quite positively to the Proma SPE-1000PV 25971000 model as the simplest and most successful model of a universal metal lathe. Many note that this is a simpler model than the Proma SPF-1000P 25100000, but it is not much inferior in terms of functionality. All the gears are metal inside and the "big brother" too, only the manufacturer regretted the oil, I had to add it so that it was really called an oil bath. They also add that the quality is comparable to Soviet machines.

- In the model of the classic machine "Red Proletarian 1K62" users emphasize reliability, safety and ease of use over many years of operation. Particularly pleased with the versatility of the work performed, reliability, workmanship and assembly quality, the unit, like no other, is suitable for individual production.

- About the budget model of the JET GHB-1340A machine worth 400 thousand rubles, users leave somewhat ambiguous reviews. Many write that the maximum savings on everything, the extreme processing parameters are on the verge of a foul. If it is used in a repair shop, then the machine is enough for little things. For production, users do not advise. The unit is made on 4+ - casting defects are visible in places, but this does not affect the work. Lightweight, so the reviews are not advised to process heavy workpieces. Processing diameter andthe length suits everyone.

Recently, the most popular universal CNC lathe. Software control expands processing possibilities to the maximum. The production process becomes fully automated. To implement the technology, it is no longer necessary to train personnel for many years, one experienced adjuster is enough for a huge fleet of equipment.

Commissioning

Despite the simplicity of the models, universal lathes are complex technical devices. They must be operated and commissioned by trained people. Despite the seeming simplicity of installing equipment, each master has to deal with non-standard tasks.

Commissioning includes 3 stages: making the foundation according to the manufacturer's drawings, setting and delivery of geometric accuracy. The standard thickness of a monolithic foundation for a frame weight of more than 1 ton is 300 mm. Only under such conditions can you set the level of the machine and give a guarantee for work for more than 1 year.

Geometry parameters

The accuracy of the machine is checked by the following parameters:

- Face and axial runout for spindle.

- Level.

- Longitudinal movement of the axes to the spindle.

- Transverse movement of the axes to the spindle.

- Spindle alignment with tailstock or sub-spindle.

- Tailstock taper runout.

- The position of the boring bar to the spindle axis (if there is a turrethead).

The accuracy of the machine is set by the manufacturer, the foreman after installation, and is also periodically controlled by maintenance personnel.

Recommended:

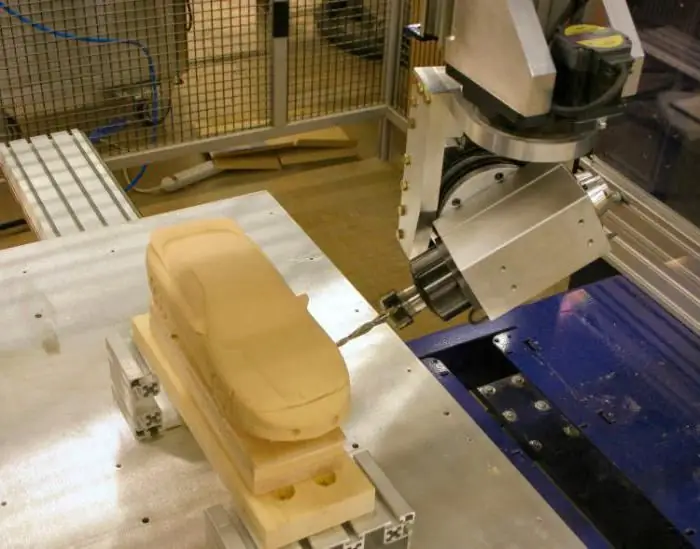

CNC small business machines - overview, types, specifications and reviews

CNC machines for small businesses: types, descriptions, features, photos. CNC machines for small businesses: overview, specifications, reviews

Fireproof paint for metal: overview, specifications, manufacturers and reviews

Fireproof paint reduces the impact of high temperatures on structures, increasing the fire resistance, which can last up to 1 hour or more. Usually structures are subject to protection, the deformation of which leads to loss of strength and destruction of buildings. The use of thin-layer coatings for protection is regulated by the fire protection code of practice

Helicopter models: overview, specifications, descriptions and reviews

Helicopter models: rating, description, features. Radio-controlled helicopter models: an overview of the best modifications, photos, reviews. Mi helicopter kit model: parameters

Copper radiators: overview, specifications, types, installation features and reviews

Copper radiators are appliances made of an amazing metal, it does not corrode, excludes the reproduction of microorganisms, and is also not afraid of chemical reactions

Universal breakdown installation: overview, features, specifications and reviews

Universal breakdown installation, or, as it is also called, UPU, is an almost indispensable device, especially when it is necessary to work with electrical equipment. The use of the UPU is a guarantee of safety at any start of an electric machine, which is characterized by very high voltage, as well as very high power