2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:31

Rip-stop fabric - what is it? This is a high-strength material that has a combined weaving structure with reinforced yarn. It has many modifications, based on the composition and certain quality characteristics.

Rip-stop fabric is used for sewing all kinds of uniforms and things for recreation and sports, expeditions and hiking, fishing and hunting, overalls. Consider what composition it has, what properties it has.

History

What is a rip-stop? The fabric takes its name from two English words: rip, which means "tear", and stop - that is, "stop".

This material owes its appearance to the military department of NATO. In the last century, by his order, the latest technology for the production of fabric was developed, which was improved and is widely used today.

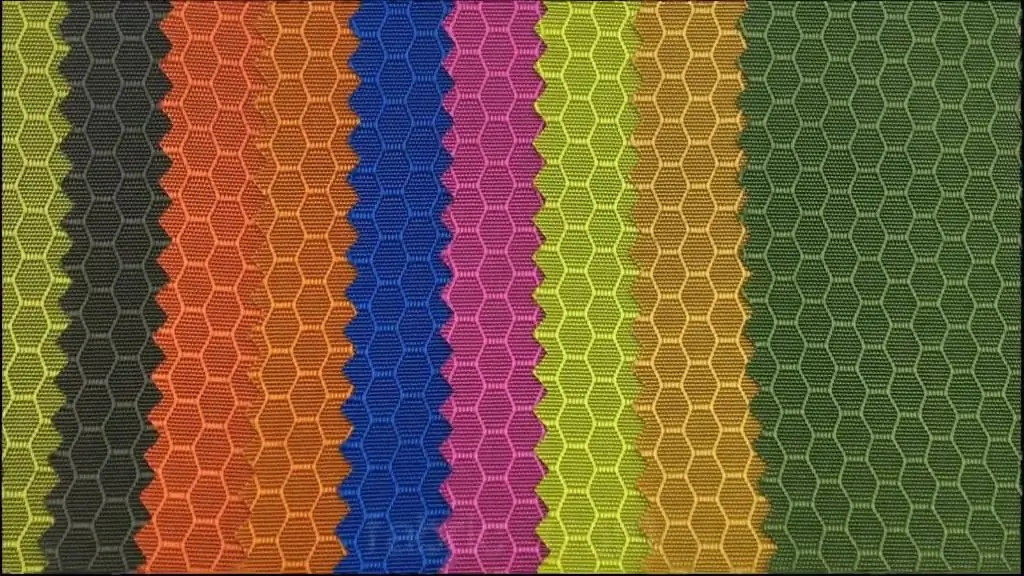

The first rip-stop was camouflage,more voluminous and rough. Thanks to modern technology, it has become possible to vary its many characteristics and colors.

Composition

Rip-stop fabric is obtained by weaving a reinforcing reinforced thread into the warp yarn. The composition of different types of this fabric is different.

Reinforced thread is produced from one or more fibers:

- Polyester.

- Nylon.

The composition of the base is even more diverse. It can be either synthetic or natural fiber. The most commonly used rip-stop fabrics are cotton, wool or silk.

Views

Depending on the constituent fibers, the following types of fabrics can be distinguished:

- Nylon rip-stop. The canvas is distinguished by maximum resistance to water and lightness. The obvious disadvantages include electrification and low light resistance.

- Polyester rip-stop. Stiffer and heavier look (compared to nylon).

- Ballistic nylon. Very hard, durable and slippery. It is made of thick polyamide yarns. The first bulletproof vests were created from ballistic multilayer nylon.

- Rip-stop blend fabric. Synthetic threads serve as a reinforcing mesh, and the main fabric is made from cotton, silk and other natural fibers. To ensure greater comfort when wearing clothes made of this material, polyester reinforcing threads are wrapped around a cotton braid. Antistatic fibers are additionally added to mixed rip-stops. Such an additive removes the electrical potential,which accumulates on synthetic materials. Depending on what the fabric is intended for, it may contain Kevlar threads or fire-resistant specialized aramid fibers.

The targeted combination of thread diameter, weave density and composition creates a large set of durable textiles with a variety of characteristics of weight, water resistance, texture, air and water permeability, frost resistance and fire resistance.

Tricks of production

We continue to understand what a rip-stop (fabric) is. This is a material that has a special weaving pattern that makes it so durable. According to the scheme, the reinforcing threads at the same distance (5-8 mm) pass crosswise through the base. In volume, the reinforcing fibers are larger than the carrier fibers, so the finished fabric acquires a checkered pattern.

Such products are comfortable to wear due to the cotton braid, which is pleasant to the touch. It was applied over reinforcing synthetics.

Mixed rip-stop is often covered with impregnations that have a specific purpose. They can be:

- Water repellent.

- Oil repellent.

- Frost resistant.

- Acid-resistant.

- Dirt-resistant.

During the production of rip-stop textiles, the following additional fibers are most often used:

- Aramid, Teflon (flame retardant) or silicone.

- Kevlar for strength.

- Antistatic - eliminates static electricity.

Fabric properties

Rip-stop has many advantages. Regardless of the fact that there are a large number of its varieties, this material has common advantages:

- Strength. Even if a hole appears on the canvas, it will not increase in size and will not spread.

- Resistant to abrasion and deformation. Things do not shrink, do not crumple, do not become covered with pellets, do not stretch.

- Water resistant. Rip-stop is waterproof and dries very quickly after washing.

- Frost resistant.

- Resistant to ultraviolet rays. The fabric coated with a certain impregnation does not fade in the sun.

- Fire resistant. Thanks to a special impregnation, the rip-stop does not burn through.

- Breathable. This quality mainly concerns clothing based on cotton weaving.

- Resistant to chemicals and dirt.

- Resistant to decay and development of microorganisms.

- Relative softness and lightness.

Rip-stop material has almost no disadvantages, except for its high cost.

Scope of application

The rip-stop fabric is used when creating products for the following areas of activity:

- Industrial.

- Military.

- Sporty.

- Medical.

- Entertaining.

- Tourist.

A more rigid and dense type of this textile is in demand when creating equipment for special purposes, workwear(narrow profile). Light and soft varieties - for tailoring and other things suitable for everyday life.

Produce the following from the material:

- Office uniform and equipment for military personnel, firefighters, employees of the Ministry of Emergency Situations, medical staff.

- Combat and military body armor, gun cases and similar protective coverings.

- Ski suits (pants, shorts, jackets, overalls), sportswear.

- Travel equipment (sleeping bags, tents), backpacks and bags.

- All kinds of tents (commercial, tourist, household).

- Case for phones and other gadgets.

- Sails for kites, paragliders, yachts.

- Cloths for balloons, parachutes.

- Banners, flags, lambrequins and more.

To give greater strength and improve the textured look of the product, they use a variety of rip-stop fabric - "oxford". It comes with water-repellent PU or PVC coatings to ensure water resistance and prevent dirt from accumulating between the fibers of the fabric.

Care instructions

Rip-stop is a fairly easy-to-use type of fabric. However, each variety has some specific instructions for use. Therefore, always read the instructions on the product label.

To general wishes for the care of the material include:

- Wash at a temperature not exceeding 50 degrees (using a machine or by hand).

- Trichlorethylene is prohibited. Otherfabric solvents are harmless, as are a variety of detergents.

- It is not recommended to wring out after washing.

- Rip-stop textiles do not need to be ironed as they do not wrinkle.

In this article, we examined what it is - rip-stop fabric. This fabric is wear-resistant and durable. Based on consumer reviews, we can say that this material has no shortcomings.

Recommended:

CVG steel: composition, application and characteristics

Studying metallurgy and all its subtleties, you involuntarily begin to experience an irresistible desire to get as much useful information as possible and spend as little time and effort as possible on it. In such a case, this article exists. It contains all the most important information related to CVG steel: deciphering the marking, studying the composition, the use of this alloy, as well as a brief excursion into substitute steels and foreign analogues. Everything you need in one place for everyone's convenience

Bas alt fabric: description, characteristics, production technology, application

Bas alt fabric: description, characteristics, production technology, application. The first attempts to create bas alt fiber. Countries where the production of bas alt fiber has been established. Properties of bas alt fabric. Products from bas alt fabric

Polymer cement mortar: composition, technical characteristics, compliance with GOST requirements, purpose and application

Polymer cement mortar is one of the modifications of conventional sand-cement mortar. Polymers can also be added to mixtures that are used when laying plaster and other facing materials. The addition of this substance to the composition helps to improve its characteristics

Jute fabric: description with photo, structure, fabric composition and application

Jute fabric is widely used to make a variety of products. In most cases, such material is, of course, used for sewing packaging bags. But jute can also be made, for example, water filters, various kinds of decorative crafts, screens, etc

Ripstop fabric: what is it, composition, characteristics, purpose and application

When asked if it is a ripstop fabric, the answer is usually about a durable material. However, the name unites a whole category of very durable materials that are produced using a special technology. It comes from the English phrase (rip - tear, stop - cessation)