2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-06-01 07:12:56

The widest range of polymer materials are polyethylene terephthalate (PET) products. The materials of this group have a lot of advantages and unique properties that determine the demand in various industries. Within this segment, PET film is especially popular. What it is? This is a form of thin resin-based roll material that can perform many different tasks.

Raw material basis

The film is made from a thermoplastic polymer in the form of polyethylene terephthalate, which is characterized by increased strength, transparency and plasticity. Depending on the particular manufacturing technique, the product can also be given improved chemical resistance properties and even the ability to withstand extreme temperatures. For example, PET preforms can withstand -40 to 75 °C on average.

At the production stage of PET film, the polymer is used in the form of a synthetic fiber. Roughly speaking, this is a plastic mass like plasticine, from which any material (by texture) can be obtained by extrusion under pressure. The product is literally squeezed out of a special apparatus, after which it is cooled and, if necessary, transported to additional molding procedures. At the same stage, various fillers, dyes and other additives can be introduced into the composition of the future film product, which have the same improving effect on individual qualities.

Product performance

Basically, product properties are determined by the basic set of qualities of raw materials, but, as already mentioned, polyethylene terephthalate can be modified during production processing. In its pure form, PET film is transparent, amorphous, heat-resistant and environmentally friendly. However, in special versions, the following qualities can be improved:

- Refractoriness - thanks to the inclusion of flame retardants.

- Mechanical strength - achieved by strengthening the polymer chain, which leads to an increase in the ability of crystallization.

- Raising the melting point and reinforcing within the structure is the effect of adding a phenylene group.

- Anti-stick.

- High adhesive power.

Main Specifications

Finished polymer products are still at the stage of technological designare calculated for certain loads, which fully applies to PET film. What is it in terms of specific characteristics? Today there is no single standard that would regulate the formats of the technical performance of this product, but the average parameters can be represented as follows:

- Roll width - up to 900 mm.

- The thickness of the roller is about 10 mm.

- Film thickness - from 125 to 175 microns.

- Density - 1.4 g/cm3.

- Operating temperature range - from -70 to 150 °С.

- Shrinkage coefficient - about 3%.

In combination, these characteristics with dielectric, water-repellent and heat-resistant qualities determine the estimated service life, which can exceed 10 years.

Varieties of PET film

A lot of film products are produced on the basis of polyethylene terephthalate, which differ not only in special performance properties, but also in their structural structure. On this basis, taking into account the specifics of the application, the following types of material can be distinguished:

- Packaging film. The basic segment in which multilayer film coatings-laminates were originally introduced. Today, this material is used to make casings for various food products, household chemicals, feed, etc.

- Printing film. A more rigid type of material in construction, which is thoroughly used for external lamination. The same group includes PET film in sheets, which covers various printingproducts to protect against mechanical damage.

- Insulating film. A special modification of PET coatings designed for electrical protection of electronic machines and devices without reducing their functionality. Some versions of this film are used for cable sheathing.

- Metallized film. Refers to the construction industry and is a thin polymer base, on the surface of which an alloy of particles of silver, gold, nickel or chromium is sprayed. Such a PET film is also used on metal-plastic windows. In the market, such products are known as heat-saving films.

PET film applications

The main purpose of the material is associated with the manufacture of containers for a variety of products from small bottles to large-sized equipment. In this capacity, the film is used both in industry and in everyday life. Models in triplex format are widely used for packaging aseptic and hot products with temperatures up to 100 °C. In some areas, the practice of using such a film is becoming obsolete. For example, not so long ago, polyethylene terephthalate was used to produce radio engineering film for audio and video recorder cassettes, but today products with a similar structure are used only as part of film air conditioners. On the other hand, in construction there is a great interest in composite products based on PET film. What it is? These are heavy duty thick garbage collection bags. Construction waste causes a lot of cleaning problems due to the risk of cuts and punctures.conventional bags, so reliable and practical PET packaging is in increasing demand.

Material recycling

It is technologically difficult to obtain secondary raw materials from polymers, but recently, with the development of new equipment for recycling used products, recycling processes have become much simpler. By the way, polyethylene terephthalate PET film is considered one of the most convenient polymeric materials in terms of processing possibilities, since it does not require special crushing and crumbling, as is the case with PET bottles, for example. Another thing is that film materials cause more problems at the stages of assembly, sorting and distribution.

Conclusion

Film products based on polyethylene terephthalate today are an indispensable technical product that is widely used in industries for various purposes. Despite the existence of analogues from other synthetic materials, it is PET film that wins unconditional competition in its niche of packaging products due to the unique combination of performance qualities. What is it in practice? What deserves such consumer confidence in this material? Even if we do not take into account the mentioned technical characteristics and protective properties with durability, an important advantage of PET film is its environmental friendliness. It is this factor that allows the use of this material in the food industry in large volumes.

Recommended:

Types of cast iron, classification, composition, properties, marking and application

The types of cast iron that exist today allow a person to create many products. Therefore, we will talk about this material in more detail in this article

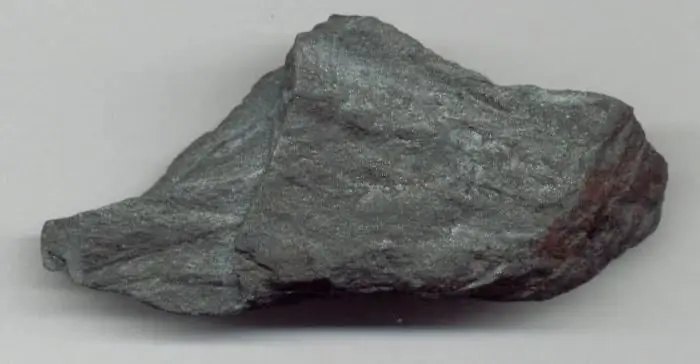

Graphite: density, properties, application features and types

Mankind uses graphite for various purposes. This substance has a unique set of properties. Graphite, whose density, types and applications are varied, deserves detailed consideration

Two-component polyurethane sealant: definition, creation, types and types, characteristics, properties and nuances of application

With long-term and high-quality sealing of seams and cracks, polyurethane two-component sealants have found their wide distribution. They have high deformation and elastic properties, therefore, they can be used as butt sealants in the field of repair and housing construction

Food packaging film: manufacturers, characteristics, purpose of the film and application

Using food storage film packaging can be very convenient. Such material weighs little, is durable and elastic. In addition, the food film is transparent, which allows the buyer to evaluate the product, including visually

Concrete mix: properties, composition, types, grades of concrete, characteristics, compliance with GOST standards and application

Among the main properties of the concrete mixture, which is also called hydrotechnical concrete, it is necessary to highlight the increased water resistance. Buildings are being built from this material to be used in swampy areas or in regions that are prone to flooding