2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-06-01 07:12:56

Today, there is almost no area of human life where cast iron is not used. This material has been known to mankind for quite a long time and has proven itself excellently from a practical point of view. Cast iron is the basis of a great variety of parts, assemblies and mechanisms, and in some cases even a self-sufficient product capable of performing the functions assigned to it. Therefore, in this article we will pay close attention to this iron-containing compound. We will also find out what types of cast iron are, their physical and chemical features.

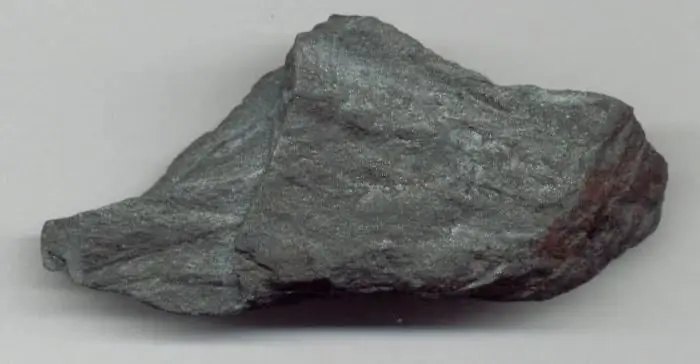

Definition

Cast iron is a truly unique alloy of iron and carbon, in which Fe is more than 90%, and C is not more than 6.67%, but not less than 2.14%. Also, carbon can be found in cast iron in the form of cementite or graphite.

Carbon gives the alloy a sufficiently high hardness, however, at the same time, it reduces malleability and ductility. As a result, cast iron is a brittle material. Also, special additives are added to certain grades of cast iron, which can give the compound certain properties. The role of alloying elements can be: nickel, chromium, vanadium, aluminum. The density index of cast iron is 7200 kilograms per cubic meter. From which it can be concluded thatthe weight of cast iron is an indicator that cannot be called small.

Historical background

Smelting iron has long been known to man. The first mention of the alloy dates back to the sixth century BC.

In ancient times, China produced cast iron with a fairly low melting point. Cast iron began to be produced in Europe around the 14th century, when blast furnaces were first used. At that time, such iron casting was used for the production of weapons, shells, construction parts.

In Russia, the production of cast iron actively began in the 16th century and then expanded rapidly. During the time of Peter I, the Russian Empire was able to bypass all the countries of the world in terms of iron production, but a hundred years later it began to lose ground again in the ferrous metallurgy market.

Cast iron has been used to create a variety of works of art since the Middle Ages. In particular, in the 10th century, Chinese masters cast a truly unique figure of a lion, whose weight exceeded 100 tons. Starting from the 15th century in Germany, and after that in other countries, cast iron casting became widespread. Fences, lattices, park sculptures, garden furniture, tombstones were made from it.

In the last years of the 18th century, iron casting was most involved in the architecture of Russia. And the 19th century was generally called the “cast iron age”, since the alloy was very actively used in architecture.

Features

There are different typescast iron, however, the average melting point of this metal compound is about 1200 degrees Celsius. This figure is 250-300 degrees less than required for steel smelting. This difference is associated with a rather high carbon content, which leads to its less close bonds with iron atoms at the molecular level.

At the time of smelting and subsequent crystallization, the carbon contained in cast iron does not have time to completely penetrate into the molecular lattice of iron, and therefore cast iron eventually turns out to be quite brittle. In this regard, it is not used where there are constant dynamic loads. But at the same time, it is excellent for those parts that have increased requirements for strength.

Production technology

Absolutely all types of cast iron are produced in a blast furnace. Actually, the smelting process itself is a rather laborious activity that requires serious material investments. One ton of pig iron requires about 550 kilograms of coke and almost a ton of water. The volume of ore loaded into the furnace will depend on the iron content. Most often, ore is used, in which iron is at least 70%. A lower concentration of the element is undesirable, since it would be uneconomical to use it.

First stage production

Smelting iron is as follows. First of all, ore is poured into the furnace, as well as coking coal grades, which serve to pressurize and maintain the required temperature inside the furnace shaft. In addition, these products during the combustion process are actively involved in the ongoing chemical reactions inthe role of iron reducing agents.

At the same time, a flux is loaded into the furnace, which serves as a catalyst. It helps the rocks to melt faster, which promotes the release of iron.

It is important to note that the ore undergoes a special pre-treatment before being loaded into the furnace. It is crushed in a crushing plant (small particles melt faster). It is then washed to remove metal-free particles. After that, the raw material is fired, due to this, sulfur and other foreign elements are removed from it.

Second stage of production

Natural gas is supplied to the furnace loaded and ready for operation through special burners. The coke heats up the raw material. In this case, carbon is released, which combines with oxygen and forms an oxide. This oxide subsequently takes part in the recovery of iron from the ore. Note that with an increase in the amount of gas in the furnace, the rate of the chemical reaction decreases, and when a certain ratio is reached, it stops altogether.

Excess carbon penetrates the melt and joins with the iron, eventually forming cast iron. All those elements that have not melted are on the surface and are eventually removed. This waste is called slag. It can also be used to produce other materials. Types of cast iron obtained in this way are called foundry and pig iron.

Differentiation

The modern classification of cast irons provides for the division of these alloys into the following types:

- White.

- Half.

- Grey with flake graphite.

- High strength nodular graphite.

- Ductile.

Let's look at each one separately.

White cast iron

This cast iron is the one in which almost all of the carbon is chemically bonded. In mechanical engineering, this alloy is not used very often, because it is hard, but very brittle. Also, it cannot be machined with various cutting tools, and therefore is used for casting parts that do not require any processing. Although this type of cast iron allows grinding with abrasive wheels. White cast iron can be both ordinary and alloyed. At the same time, welding it causes difficulties, since it is accompanied by the formation of various cracks during cooling or heating, and also due to the heterogeneity of the structure that forms at the welding point.

White wear-resistant cast irons are obtained by primary crystallization of a liquid alloy during rapid cooling. They are most commonly used for dry friction applications (e.g. brake pads) or for the production of parts with increased wear and heat resistance (rolling mill rolls).

By the way, white cast iron got its name due to the fact that the appearance of its fracture is a light-crystalline, radiant surface. The structure of this cast iron is a combination of ledeburite, perlite and secondary cementite. If this cast iron is alloyed, then pearlite is transformed intotroostite, austenite or martensite.

Half cast iron

The classification of cast irons would be incomplete without mentioning this variety of metal alloy.

The specified cast iron is characterized by a combination of carbide eutectics and graphite in its structure. In general, the full-fledged structure has the following form: graphite, pearlite, ledeburite. If the cast iron is subjected to heat treatment or alloying, this will lead to the formation of austenite, martensite or acicular troostite.

This type of cast iron is quite brittle, so its use is very limited. The alloy itself got its name because its fracture is a combination of dark and light areas of the crystalline structure.

The most common engineering material

Gray cast iron GOST 1412-85 contains about 3.5% carbon, from 1.9 to 2.5% silicon, up to 0.8% manganese, up to 0.3% phosphorus and less than 0, 12% sulfur.

Graphite in such cast iron has a lamellar shape. It does not require special modification.

Graphite plates have a strong weakening effect, and therefore gray cast iron is characterized by very low impact strength and almost no elongation (less than 0.5%).

Grey cast iron is well machined. The alloy structure can be as follows:

- Ferrite-graphite.

- Ferrite-pearlite-graphite.

- Perlite-graphite.

Grey cast iron works much better in compression than in tension. He alsowelds quite well, but this requires preheating, and special cast iron rods with a high content of silicon and carbon should be used as filler material. Without preheating, welding will be difficult because the cast iron will bleach in the weld area.

Grey cast iron is used to produce parts that operate without shock loading (pulleys, covers, beds).

The designation of this cast iron occurs according to the following principle: SCH 25-52. Two letters indicate that this is gray cast iron, the number 25 is an indicator of the tensile strength (in MPa or kgf / mm 2), the number 52 is the tensile strength at the moment of bending.

Ductile iron

Nodular cast iron is fundamentally different from its other "brothers" in that it contains nodular graphite. It is obtained by introducing special modifiers (Mg, Ce) into the liquid alloy. The number of graphite inclusions and their linear dimensions can be different.

What is good about spheroidal graphite? The fact that such a form minimally weakens the metal base, which, in turn, can be pearlitic, ferritic or pearlitic-ferritic.

Due to the use of heat treatment or alloying, the cast iron base can be acicular-troostite, martensitic, austenitic.

Grades of ductile iron are different, but in general terms, its designation is as follows: VCh 40-5. It is easy to guess that HF is high-strength cast iron, the number 40 is an indicatortensile strength (kgf/mm2), the number 5 is relative to elongation, expressed as a percentage.

Ductile iron

The structure of malleable iron is the presence of graphite in it in flaky or spherical form. At the same time, flaky graphite can have different fineness and compactness, which, in turn, has a direct impact on the mechanical properties of cast iron.

Industrial ductile iron is often produced with a ferritic base, which provides greater ductility.

The fracture appearance of ferritic ductile iron has a black velvety appearance. The higher the amount of perlite in the structure, the lighter the fracture will become.

In general, ductile iron is obtained from white iron castings due to long languishing in furnaces heated to a temperature of 800-950 degrees Celsius.

Today, there are two ways to make ductile iron: European and American.

The American method is to languish the alloy in sand at a temperature of 800-850 degrees. In this process, graphite is located between grains of the purest iron. As a result, cast iron becomes viscous.

In the European method, castings are languishing in iron ore. The temperature at the same time is about 850-950 degrees Celsius. Carbon passes into iron ore, due to which the surface layer of the castings is decarburized and becomes soft. Cast iron becomes malleable, while the core remains brittle.

Marking malleable iron: CCH 40-6, where CCH is, of course, malleable iron; 40 - tensile strength index;6 - elongation, %.

Other indicators

As for the division of cast irons by strength, the following classification is applied here:

- Typical strength: σv up to 20 kg/mm2.

- Increased strength: σв=20 - 38 kg/mm2.

- High strength: σv=40 kg/mm2 and above.

According to ductility, cast irons are divided into:

- Inflexible - less than 1% elongation.

- Low plastic - from 1% to 5%.

- Plastic - from 5% to 10%.

- Increased plasticity - more than 10%.

In conclusion, I would also like to note that the properties of any cast iron are quite significantly affected even by the shape and nature of the pour.

Recommended:

Designation of alloying elements in steel: classification, properties, marking, application

Today, a variety of steels are used in many industries. A variety of quality, mechanical and physical properties is achieved by alloying the metal. The designation of alloying elements in steel helps to determine which components were introduced into the composition, as well as their quantitative content

Diameters and dimensions of cast iron sewer pipes. Types and features

Cast iron pipes are used today in the laying of external and internal sewerage systems. Products can be channelless and channel. Their service life can reach 100 years. Connecting elements and assortment of sewer pipes is determined by GOST 6942-98. After reading the documentation, you will be able to understand what parameters the pipes should have

Alloy cast iron: grades, properties and applications

Alloyed iron is a material that is produced by smelting in blast furnaces. It can contain different amounts of carbon. Depending on the quantitative content of this substance, two types of cast iron are distinguished. The first is called conversion, or white, and the second is gray, or foundry

Ductile iron: properties, marking and scope

Cast iron is a hard, corrosion-resistant, but brittle iron-carbon alloy with carbon content C ranging from 2.14 to 6.67%. Despite the presence of characteristic shortcomings, it has a variety of types, properties, applications. Ductile iron is widely used

White cast iron: properties, application, structure and features

Initially, the technology of casting iron was first mastered in China in the 10th century, after which it became widespread in other countries of the world. A prominent representative of such an alloy is white cast iron, which is used in mechanical engineering for the manufacture of parts, in industry and in everyday life