2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

In general, beautiful metal embossing causes great delight in many people, every detail looks so clear and filigree. And one of the ways is embossing. It is named after the British designer and inventor William Congreve, who invented this embossing technique in the 19th century.

Today hot stamping is the most popular embossing method, which is widely used in marketing and in various markets (advertising and souvenir products, design projects).

Features of embossing

This method is the finishing touch when processing various materials. That is why it can be used on virtually all types of products, regardless of the source material. It is important that when the application is carried out, the embossing is done with the help of two forms - convex and concave. Also worth noting:

- no need to add additional inks and dyes;

- visual improvement of the look of the finishedproducts by applying a layer of protective coating.

Embossing also looks good in terms of variety of types (three major categories stand out):

Applying paint materials - dyed, mixed (blind, using different stamps), unpainted

- Variability of artistic technologies - single-level (the final form is characterized by the use of one pattern formation located on the same level), multi-level (many patterns and on different planes), combined (several technologies are used at once, for example, the use of foil stamping and hot stamping). In any case, stamping is the creation of a rather beautiful product that has an attractive and imposing appearance, alluring look.

- Use of auxiliary material - with foil (instant print with foil applied to the surface at a working temperature of up to 160 degrees), without foil (standard print-cliché with a temperature of no more than 60 degrees).

Embossing today

In general, today the practice of various embossing is very wide. Hot stamping is no exception. This is:

- business cards, postcards;

- diplomas, award lists, diplomas;

- folders, folders;

- notebooks, notebooks and conduits;

- gift decoration (boxes, packaging);

- small stationery and paper.

With the help of this embossing method, it is possible to convey not only the external beauty of the product, but also presentability withsophistication. For advertising and marketing products, this approach is already 50% successful.

Besides, if we compare hot stamping and embossing, the difference is immediately evident. Embossing makes it possible to work with virtually any material - paper, cardboard, plastic, polyethylene, fabrics and leather.

Relief stamping technology

To perform hot stamping, the use of special auxiliary tools and forms (males and clichés) is required. Crucible and printing presses are used as the main equipment. The process itself consists of several important steps:

- Preparing the working state of the stamp - cold, warm or hot.

- Assembly of clichés and patrices. The template of the final drawing is directed towards the source material, and on the other side the counter matrix is placed.

- Depending on the template option, after embossing, a three-dimensional image is created (concave or convex).

- Setting the embossing standard - the finished pattern should be twice as thick as the material on which it is applied.

For the foil method, similar methods are used, with the only additional point - a thin sheet of golden or silver foil is placed between the working canvas and the hot stamping.

Advantages of embossing

Among all the embossing methods, hot stamping is perhaps the most popular. It is characterized by a considerable number of advantages:

- attractive appearance;

- creating all kinds of packaging shapes;

- cost reduction due to the uselessness of the use of additional paints;

- large selection of clichés;

- a unique way to print.

Besides, the usual embossing and hot stamping also have differences in the choice of material for the cliché template. In addition to the widespread copper, brass is also used (one of the most durable and high-quality), polymer (low cost, disposable), heavy metals (zinc, magnesium - it is recommended to use infrequently).

In any case, the use of this unique embossing method is gaining more and more popularity today. This is not surprising, because ready-made embossing patterns last a very long time, do not lose their original color, are universal and immediately catch the eye.

Recommended:

Post-print processing of printing products

Printing is not always considered the final stage in the printing industry. Post-print processing is often required to protect the product from damage and give it a decorative look. This work is carried out by various printers. There are different types of post-print processing, which will be discussed in the article

Do I need to register the IP seal? Can IP work without printing

Does an individual entrepreneur need a seal? Is it subject to mandatory registration? The article will tell you in detail what types of seals are, who makes them and how to order a layout. And also, why an individual entrepreneur should still acquire a seal and register it with state bodies

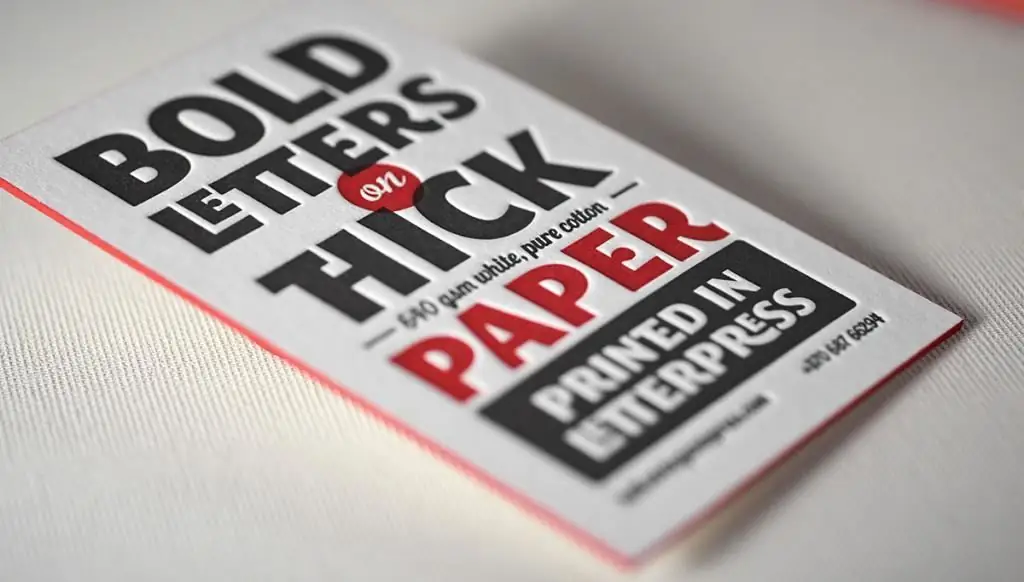

Letterpress is Letterpress printing technology, modern stages of development, necessary equipment, advantages and disadvantages of this type of printing

Letterpress is one of the typical methods of applying information using a relief matrix. The elements that protrude are covered with paint in the form of a paste, and then pressed against the paper. Thus, various mass periodicals, reference books, books and newspapers are replicated

Ink pad for printing

Many office workers have an ink pad on their desk, designed to soak the stamp in special ink. Even if it is not immediately visible, we can safely say that it is present, because in modern stamping equipment this device is hidden from view

Embossing is what? Embossing of plastic bank cards

The procedure for applying raised inscriptions to a plastic card is called embossing. How and why is this done, what mechanisms are used for this? Let's find out more