2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:32

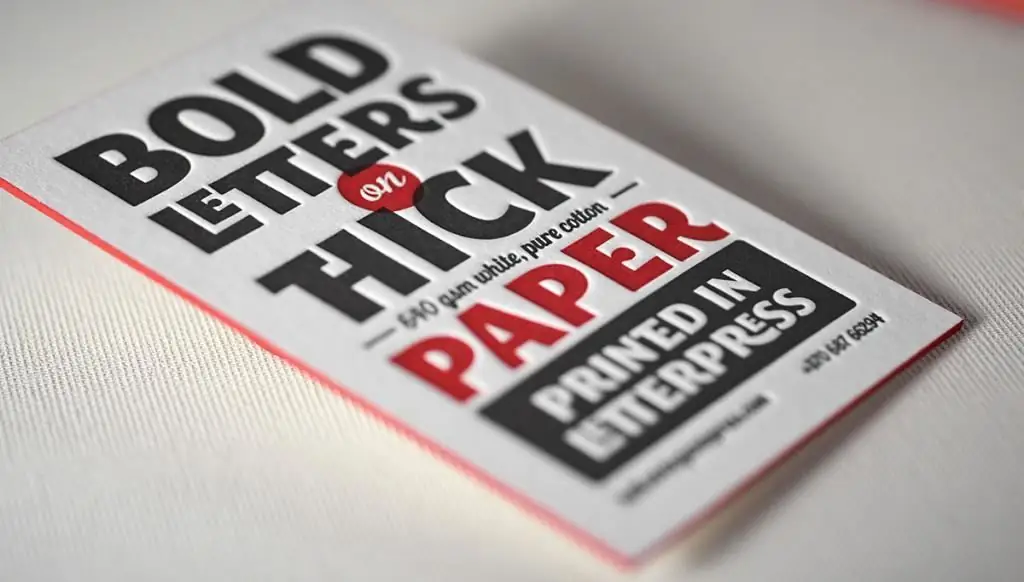

Letterpress is one of the typical methods of applying information using a relief matrix. The elements that protrude are covered with paint in the form of a paste, and then pressed against the paper. In this way, various mass periodicals, reference books, books and newspapers are replicated.

Development of technology

Earlier, the forms were in the form of smooth boards, on which drawings and words were carved. This printing method is called xylography. It is sometimes used in our time, if you want to create art reproductions. The invention of typesetting plates led to the development of printing. Each page was made up of individual characters and letters. Symbolic elements were cast from lead or carved from wood. Then there were letterpress machines, where the text was typed much faster. The protruding letters were rolled with paint, and under the press they made an imprint on paper.

One of the last stages of development was the use of printing formsfrom photopolymers. There are aluminum-based plates - for flat printing, film - rotary.

Current metal molds are made using methods:

- milling;

- etching;

- engravings (cliches, stamps).

Their use is limited. This is due to the fact that the composition contains lead, a metal quite harmful to he alth. Similar forms are used for:

- creating a natural leather pattern;

- embossed;

- foiling.

One of the well-known types of letterpress printing is flexography. This letterpress method uses flexible forms made of photopolymers with a small 0.5-0.7 mm deepening of whitespace elements. An impression with this method is obtained using a cylinder, a polymer matrix is fixed on its surface. As a result, the pattern is continuous with repeating parts of the pattern. Paper width and cylinder diameter determine what it will be:

- wallpaper;

- packaging;

- labels.

Impression specifics

High resolution printing in:

- paper;

- foil;

- self-adhesive film;

- polyethylene;

- vinyl;

- cardboard including corrugated.

Bright pictures consist of tiny square or round prints. Color printing uses 4 inks. On these images, a raster rosette is visible - a distinct structural pattern.

Iflook at the letterpress photo, you can understand that the use of technology in printing does not go beyond the resolution of printing. The limit for this method is the publishing house of newspaper and book text, as well as one- and multi-color illustrations. If you study prints on printed surfaces through a magnifying glass, you can see thickening of paint along the contour of the elements. As a result, bitmap images acquire color saturation, and characters and letters have a sharp outline. Serrated fonts and thin strokes are smooth and continuous.

This type of printing (a form of letterpress printing) suggests that pressure is needed to transfer the ink to the paper. As a result, a convex outline is formed on the back side of the printed base, which is noticeable, and can also be felt by hand. A fresh print smells like kerosene because the binders in printing inks are made from petroleum products.

Advantages and disadvantages of letterpress

Letterpress technology stands out for its simplicity, which is one of the plus points. Other benefits include:

- stable picture quality;

- reliable technology;

- independence of the humidity of the printed base;

- legibility and clarity of writing on prints;

- low production cost;

- low equipment cost.

The positive side of letterpress is that you can use water-soluble, alcohol and oilpaint.

Despite the fact that high-resolution photo printing looks as perfect as possible, this technology has certain disadvantages, one of them is the low resolution of the equipment. A convex relief is formed on the print from the back side. The downside is low performance, in other words, low speed. Printing of this type of resolution is economically feasible to use in the production of books and newspapers. It is noted that in order to cast a flexible photopolymer matrix, you need to spend 1-2 hours, and metal cliches will have to be made for more than one day, since such a process is painstaking and costly.

Scope of letterpress printing

Letterpress is a type of printing in which printed elements are located higher than whitespace. Not used in advertising. It continues to print newspapers, manuals, labels, flyers and letterheads in print shops with outdated equipment.

Today, flexo printing is more common, where a flexible printing form is used. It is used in production:

- stickers and stickers;

- labels for food and industrial products, cardboard tags;

- tickets with transverse perforation and numbering;

- candy wrappers;

- disposable tableware;

- labels for clothes;

- plastic and paper bags;

- flexible packaging for food, drinks and so on.

Types of letterpress equipment

High wayprinting involves the use of various types of equipment, one of which is a platen printing machine. In it, the form is attached to an immovable flat surface, on which the printing rollers roll ink. Next comes the paper and presses against the form.

In the rotary printing press, the printing plate is not flat. It is located on the forme cylinder, which during the process is in contact with the second cylinder. It is the other cylinder that applies the paint to the mold. In this case, the typing speed can be increased.

In a flatbed press, the form moves back and forth in contact with the print cylinder.

Servo driven machines

The servo machine is an automated electronically controlled device. This model is considered very productive and productive, and all thanks to improved print quality and a minimum of waste. Such machines are distinguished by optimal independent control of each print unit. They have an easy-to-understand touch screen and a winder and unwinder that allows you to adjust the tension. From the central control of the servo machine, as well as locally, printing plates can be changed quickly.

Servo driven rotary machines

The HTC 260/460 servo-driven rotary machine allows a maximum of 12 colors to be used. Such multicolor is typical for letterpress printing and flexography. The device can be completed with rotary stencils. The main print media are laminates and self-adhesive paper. Thisthe machine is designed for the production of blanks for laminated tubes and flexible packaging. The main features of HTC 260/460 are:

- almost zero waste;

- complete cold foil stamping;

- Lamination Acceptability.

All roll-to-roll web printing equipment is the perfect solution for high-volume label and packaging applications. The high productivity of rotary machines is due to the use of rolls.

The difference between offset and letterpress

Customers of printers who are not tech-savvy often confuse the two types of printing. Offset printing technology does not provide for the presence of protruding parts on the surface of the form. The transfer of ink to paper occurs through an offset cylinder, which is an intermediate element. During printing, these elements are moistened. Materials that differ in physical properties are used to make print marks and spaces.

In letterpress printing characters rise above whitespace. The printing process takes place with a strong pressure of the form to the paper. The printed matrix is made of one material. It does not need to be moistened during the process.

The common thing between these two types of printing is that they decorate volumetric objects. The print is transferred to paper by a convex matrix, an offset cylinder is used.

Conclusion

Letterpress is the beginning of all technologyprinted production. Today it is continuously improved.

This technology uses a viscous paint that does not spread over the form, which means that gaps do not need to be cleaned. As a result, printed forms become more convenient to use. Although flexo and offset are modern versions of letterpress, the latter is still used today in newspapers and books.

Recommended:

Smoking shop: preparation of necessary documents, drawing up a business plan, selection of necessary equipment, goals and stages of development

The article deals with such a business as a smoke shop. Learn how to start a business and where to start. About how to choose equipment and how it should be. About what you need to pay attention to when choosing suppliers, and about the process of producing smoked products

Hairdresser at home: preparation of necessary documents, drawing up a business plan, selection of necessary equipment, goals and stages of development

Hairdressing business for creative people is a very promising and interesting business. Well, if there is no money to open a large salon, then at first it is quite possible to start your project from the first stage. For this, a hairdressing salon at home can be organized, which does not require large investments. Is it worth it to engage in such a business, and what steps will you need to go through to open it?

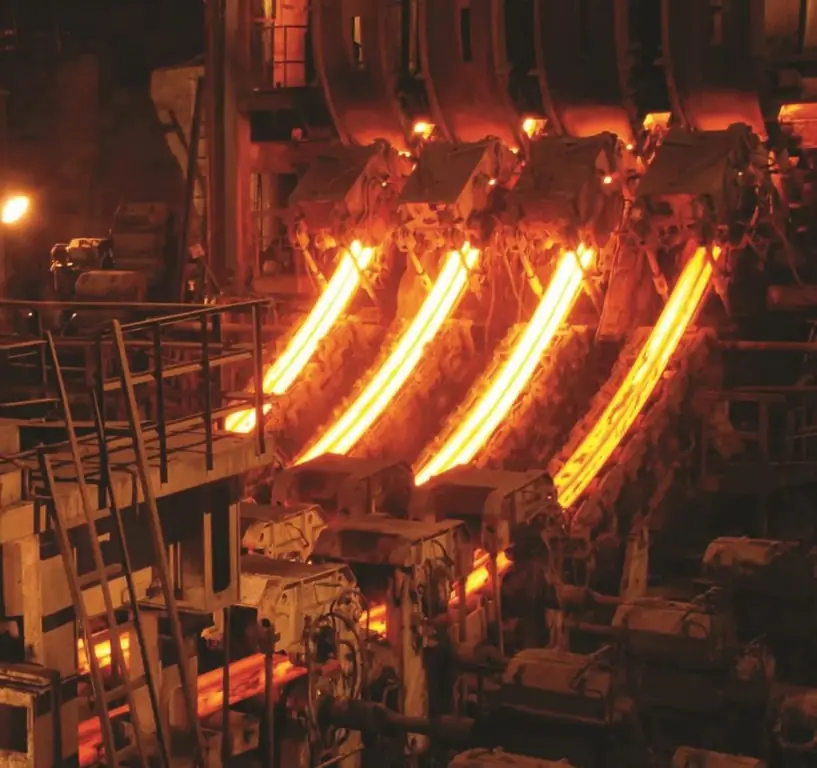

Continuous casting of steel: principle of operation, necessary equipment, advantages and disadvantages of the method

Today, a huge number of various things, parts, etc. are made of steel. Naturally, this requires a large amount of source material. Therefore, the plants have long been using the method of continuous casting of steel, characterized by the most important feature - high productivity

Diesel submarines: history of creation, boat projects, principle of operation, advantages, disadvantages and stages of development

The idea of creating a submersible moving under water, actually a prototype of a submarine (hereinafter referred to as a submarine), arose long before their actual appearance in the 18th century. There are no exact descriptions of underwater vehicles in numerous legends, nor in the Renaissance genius Leonardo da Vinci

Alternative energy in Russia: concept, classification and types, stages of development, necessary equipment and application

Alternative energy in Russia is currently quite poorly developed. This is supported by the fact that less than 1% of all energy produced comes from such sources. On a national scale, this is extremely small