2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:26

Printing is not always considered the final stage in the printing industry. Post-print processing is often required to protect the product from damage and give it a decorative look. This work is carried out by various printers. There are different types of post-print processing, which will be discussed in the article.

Cutting

This procedure can also be performed before printing, during the preparation of paper for shipment to the press, and it is always performed on printed products. Cutting is needed to align the edges of products, cut products, for example, flyers, business cards. The paper is cut in a stack, this must be taken into account when creating a layout for printing - make flights that protect the image or text.

Cutting allows you to make the product neater. Since the products are processed in a pack, even a slight shift will cause a marriage of circulation. Quality is determined by the evenness of the edges of finished products. The resulting printed products have an original look.

Fold andcreasing

Folding - post-print processing for bending sheets. Without the procedure, it is impossible to get multi-page products, booklets, newspapers. The fold is the fold line of the paper. For work, special equipment is used. In this case, several folding options are used - euro, books, gate. Paper must be up to 170 g/m2.

The thick paper is folded with a creaser. On a special device, the sheets are squeezed along the fold line. A groove appears - big. After that, folding is performed. Thanks to this sequence, high-quality folds without creases are obtained. Creasing is needed to receive paper bags, folders.

Punching and die cutting

If you need to print non-rectangular products, the punching procedure is performed. According to the customer's layout, a cutting mold is created for a special device - a crucible.

Cutting is used to obtain postcards, labels, boxes, folders, where the design has a complex outline. The procedure is also used to decorate products. It is used in receiving boxes, folders-folders.

Booklet

This post-printing process allows you to assemble the sheets into a single product. To do this, use:

- stitching on wire;

- adhesive seamless bonding;

- Spring Wire-O;

- stitching with threads.

Embossing

Foil stamping is in demand. With its help, the attractiveness of the finished product improves, so it is used for gift products. Foilit can be metallized, color and holographic. The embossing finishing procedure involves pressing the foil onto the printed product.

A cliché is created for this work. Hot stamping is another popular embossing option. It is used in obtaining a relief image that will be on the surface of the product. If the execution procedure is carried out without foil, embossing is called blind embossing. Hot stamping - post-printing processing for postcards, beautiful covers for books, diplomas.

Lamination

With this procedure, a special device covers the products with a thin film. Thanks to this, the product will be durable, attractive. Lamination prevents fingerprints. Leaves are tough and durable. This protects the product from dirt.

Lamination is divided into several types:

- glossy - makes the image brighter and richer;

- matte - there will be no glare on the surface;

- textured - the surface is not smooth.

Varnishing

This post-print processing of products allows you to transform the appearance of the product. Two types of procedure are in demand:

- VD varnished. The image is covered with water-dispersion varnish. The procedure is performed when printing. VD-lacquer is used to cover products with large fragments of patterns sealed with a uniform ink.

- UV varnish. A varnish is used that dries under ultraviolet radiation. This finish gives a brightvarnish effect. The procedure is carried out to select fragments of the picture.

Perforations

Such post-print processing of printed products is also considered to be in demand. The procedure is performed to obtain products with tear-off leaves. Usually it is used for flyers, calendars, tickets, announcements. Perforation is needed for products such as notebooks, brochures.

Laminating

The procedure is used to receive packaging or POS materials. To do this, a film, design paper or thin cardboard with a printed pattern is glued to a cardboard or plastic base. This type of packaging looks original, besides it is very durable.

Slimovka

Slim-cardboard is used for packaging linen, toys, appliances, light bulbs. Slimovka is the procedure for gluing cardboard to cardboard. The top layer has a printed image and a water-dispersion or UV varnish.

Hardcover

This procedure involves stitching the printed matter onto a thread. This design option for multi-page products is used for a long service life, for example, books.

Hardcover is called folded sheets, binding roof and parts attached to it (endpapers). The binding roof is created on the basis of binding cardboard, top covered with paper, bumvinyl and other materials, leather.

Thus, many types of post-print processing are applied. You can order them individually.wishes. Taking into account all the important parameters, high-quality and beautiful printed products are obtained.

Recommended:

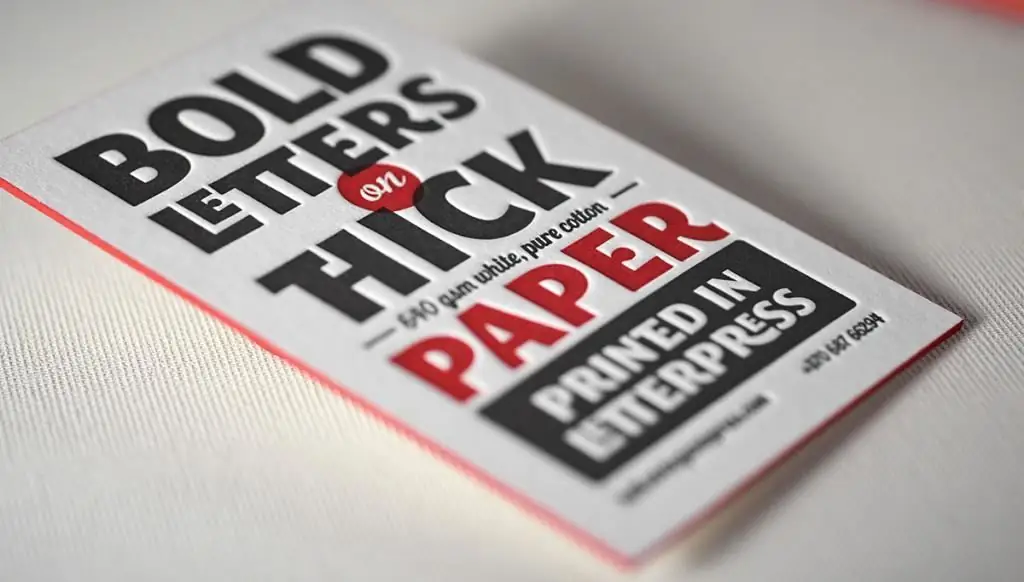

Letterpress is Letterpress printing technology, modern stages of development, necessary equipment, advantages and disadvantages of this type of printing

Letterpress is one of the typical methods of applying information using a relief matrix. The elements that protrude are covered with paint in the form of a paste, and then pressed against the paper. Thus, various mass periodicals, reference books, books and newspapers are replicated

Meat processing enterprises, meat processing plants in Russia: rating, products

Today, a huge number of enterprises are engaged in meat processing. Moreover, some are known throughout the country, and some - only on the territory of their region. We offer to evaluate the most powerful meat processing enterprises in Russia in terms of productivity, which have the largest revenues and high turnover. Below is a list of such companies. It is based on consumer feedback

Meat: processing. Equipment for meat and poultry processing. Production, storage and processing of meat

Information of state statistics show that the volume of meat, milk and poultry consumed by the population has significantly decreased in recent years. This is caused not only by the pricing policy of manufacturers, but also by the banal shortage of these products, the required volumes of which simply do not have time to produce. But meat, the processing of which is an extremely profitable business, is very important for human he alth

Amur Gas Processing Plant (Amur Gas Processing Plant) - the largest construction site in Russia

Amur GPP in 2017 is the largest construction project in Russia. After commissioning, this enterprise will supply the market with 60 million cubic meters of helium alone. Among other things, this plant is an important component of the grandiose project "Power of Siberia"

REMIT Meat Processing Plant LLC: feedback from customers and employees, manufactured products and quality of meat products

REMIT reviews are of interest to customers who are considering options for cooperation with this company, and employees who expect to get a well-paid and stable job. In this article, we will talk about this meat processing plant, what products it produces, whether its quality corresponds to the declared one, what its employees and partners say about the enterprise