2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-06-01 07:12:56

Aspiration is the process of ventilation of industrial premises with high dust content. Such areas are equipped with special filtration equipment. In particular, gas-cleaning and dust-collecting installations are used. The premises of various enterprises are equipped with such equipment: from factories for the industrial production of bricks to grain processing plants. Let's consider further what are the dust-collecting installations (UVP).

Classification features

Ventilation dust collector (UVP) is an equipment designed for air filtration. The separation of impurities is carried out in special filters.

Depending on the mechanism of action, these elements are divided into:

- Gravity.

- Wet.

- Electrical.

- Oiled.

- Inertial.

- Porous.

- Combined.

- Acoustic.

- Cloth etc.

Main types of equipment

Depending on the degree of filtration, the installations can be:

- Rough cleaning. The efficiency of particle retention in such equipment is 40-70%. Such units include large-sized cyclones, sedimentation chambers.

- Medium cleaning. They provide 70-90% particle retention. This category includes louvre, rotary units, cyclones, etc.

- Fine cleaning. In them, the particle retention rate can reach 90-99.9%. This group includes hose, electric, roll, cell, foam units, etc.

Depending on the areas of application, the devices are divided into 2 categories. The first includes units used to filter ventilation and industrial emissions into the atmosphere, the second - devices designed to clean the flowing streams, as well as air masses returned to the workshop during recycling. Enterprises can use different dust collection plants at the same time. The price of equipment ranges from 36 to 400 thousand rubles.

Technical and economic indicators

They determine how efficient the operation of dust collection plants at a particular enterprise. The key technical and economic indicators include:

- Dust capacity.

- Hydraulic resistance.

- Performance.

- Dust collection efficiency (fractional and total).

- Power consumption.

- Filtration cost.

- Maintenance costs.

Comparative characteristics

The simplest is the dust collectorinstallation, the mechanism of action of which is based on gravity. As a rule, coarse filtering is carried out in it. Particle collection efficiency is no more than 50%. In this case, elements larger than 50 microns are absorbed. Cyclone is a more efficient dust collection unit. In it, filtration is based on the application of centrifugal force. In the process of rotation, particles of substances are thrown to the walls of the unit, and then fall into a special hopper. Purified air, rotating, exits the unit through a pipe. Cyclone filtration efficiency is 80-90% today.

Currently, such units have a variety of designs. If it is necessary to clean a large volume of air flow, several devices are combined into groups or battery cyclones are used. They are presented in the form of a large number of small units installed in one housing and placed on one bunker. The most popular today, however, are wet dust collectors. Due to contact with the liquid medium, the particles are wetted and enlarged, and then removed from the apparatus in the form of sludge. Such units can have a variety of designs. For example, it can be rotocyclones, disintegrators, and so on.

Foam units also belong to the class of wet installations. They supply water to a perforated grate. Filtered air passes through it. A threshold (drain partition) is provided on the grate. It allows you to maintain a certain thickness of the foam layer. Such a dust-collectingThe unit is highly efficient - up to 99%. The unit is able to filter particles larger than 15 microns. The industry produces devices PGP-LTI and PGS-LTI with a capacity of 3-50 thousand m/h.

Schemes

Foam dust collector includes:

- Receiver box.

- Case.

- Grate.

- Threshold.

- Drainer box.

The bag filter has the following design:

- Inlet pipe.

- Sleeve.

- Pendant.

- Shaking mechanism.

- Outlet.

- Bunker.

The electrostatic precipitator consists of:

- Inlet pipe.

- Corona electrode.

- Filter housings (collecting electrode).

- outlet.

- Bunker.

- Rectifier.

Mechanism of action

Hose ventilation dust-collecting unit filters the air through the fabric. It is sewn together in a special way and placed in a sealed case of the device. The air being cleaned is sucked off by the fan from the filter and released into the atmosphere. The bags are periodically cleaned using a backflush shaking mechanism. Filters can be pressure and suction type. For their manufacture, a dense synthetic or natural fabric is used. The effectiveness of the sleeves is 95-99%. In practice, the most common filters are FTNS, FRM, FVK.

Electric devices are widely used in the treatment of industrial and ventilation emissions. The mechanism of their work is based on the following: when gas is passed between two differently charged plates, the air environment is ionized. Ions and dust particles collide, the latter receive electric charges. Under their action, they begin to move to the electrodes of the opposite sign and settle there. The filtration efficiency in such devices is 99.9%. Electrical installations are considered economical in operation. They can filter flows at temperatures up to 450 degrees. However, electrical installations cannot be used to trap explosive particles.

Specific aspiration

This process involves not only the removal of dust from the air, but also its additional purification. The system functions in such a way that prevents the accumulation of particles and the creation of "traffic jams". This ensures the uninterrupted operation of personnel and equipment in the room. Taking into account the huge volume of waste in industrial enterprises, it can be concluded that aspiration is becoming even more in demand due to the established standards of he alth and safety when working in hazardous conditions.

This method differs from other indoor air purification methods in that the systems are located at a certain angle. This prevents the formation of stagnant zones and localizes areas of maximum emission of contaminants. As a result, a multiplicative filtering effect is realized. The concentration of harmful compounds at the same time does not go beyond the permissible limits.borders.

Chip blowers

Aspiration systems are used not only in the chemical and metallurgical industries, but also in woodworking, grinding and crushing shops. In such premises, the installation of filtering equipment requires special knowledge, so professionals are invited to install it. The design of an aspiration system begins with an examination of the premises. Based on it, a preliminary calculation of the power and dimensions of the equipment is made. In the furniture industry there is a huge amount of fine waste. They must be removed from the workspace without fail. For this, a chip removal system is used. The equipment is considered a type of suction machine.

The chip blower can remove particles up to 5 microns in diameter. In the equipment cyclone there is a special fan and filtered bags. A separate machine is connected to the chip blower using a flexible duct system made of reinforced or corrugated pipe. The principle of operation is quite simple. The fan sucks in polluted air, which is filtered. Dust particles are collected in a bag. From there they are sent to a special filter for final cleaning. At maximum filling, the bag is removed and cleaned or replaced with a new one. Chip blowers are easy to connect and easy to transport.

Requirements

The devices must function smoothly, reliably, with indicators corresponding to the design orobtained during the adjustment activities and agreed with the developer. Gas treatment plants must be equipped with auxiliary devices and inventory. When using such units, responsible persons maintain documentation. It reflects the main indicators by which the mode of operation of the equipment is characterized. In particular, we are talking about a deviation from the optimal scheme of operation, identified malfunctions, failure of individual devices or the entire complex as a whole, etc. All units must be registered with the State Inspectorate for Gas Cleaning. At least once every six months, the units should be inspected to assess the technical condition. This procedure is carried out by a commission appointed by the head of the enterprise.

General rules for the operation of gas cleaning and dust collection plants

It is not allowed to use technological equipment when the filtering devices are turned off. In each case of turning off the cleaning device while the machine is running, the management of the organization is obliged to notify the State Inspectorate. In this case, it is necessary to obtain an approved emission permit from the supervisory authorities.

When operating dust-collecting installations for gas filtration with a high content of explosive (combustible) elements, it is necessary to carefully ensure that the specified pressure indicators and tightness of structures are maintained, and that devices and communications are properly purged to prevent ignition and explosion.

Recommended:

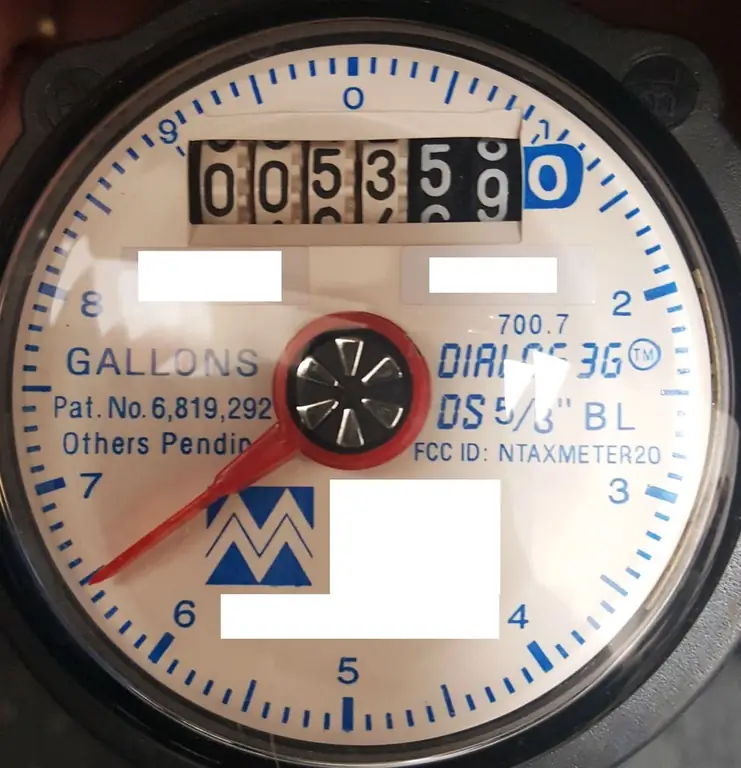

Shelf life of water meters: period of service and operation, verification periods, operating rules and time of use of hot and cold water meters

The shelf life of water meters varies. It depends on its quality, the condition of the pipes, the connection to cold or hot water, the manufacturer. On average, manufacturers claim about 8-10 years of operation of devices. In this case, the owner is obliged to carry out their verification within the time limits established by law. We will tell you more about this and some other points in the article

Diamond boring machine: types, device, operating principle and operating conditions

The combination of a complex cutting direction configuration and solid-state working equipment allows diamond boring equipment to perform extremely delicate and critical metalworking operations. Such units are trusted with the operations of creating shaped surfaces, hole correction, dressing of ends, etc. At the same time, the diamond boring machine is universal in terms of application possibilities in various fields. It is used not only in specialized industries, but also in private workshops

Loading cranes: types and operating rules

Many years ago, lifting equipment was one of the main achievements of technology. But today, when advanced technologies and modern materials are being actively introduced, it is gradually becoming more traditional

Duration of the operating cycle. What is an operating cycle?

The company will not have problems with a lack of current assets if the management begins to strictly control the proportions between equity and debt capital, through which operations are financed

Dust collecting unit (PU). Types of dust collecting units

Many industrial processes are accompanied by air pollution, which necessitates timely cleaning of the workspace to improve sanitary conditions. Ventilation systems, even in industrial design, are not able to provide sufficient performance for the removal of fine particles produced by processing equipment. Therefore, in solving such problems, special dust-collecting units of various types and modifications are used