2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

Processing hard building materials often requires the use of special tools. The sheet metal cutting operation is one of the most common. Quite diverse and equipment that allows you to perform it qualitatively. Today, such tasks are solved by thermal devices, laser systems, as well as sandblasting hydroabrasive machines. At the same time, traditional mechanical tools remain relevant, which also give a good result. These devices include guillotine shears, which are on the market in a wide range.

Varieties of guillotines for metal cutting

Conventionally, the group of guillotine cutters can be divided into three segments. The first will include the most powerful electrical machines that operate on a drive mechanism and include a full-fledged engine in the device. These are the most powerful guillotine shears, which can cut metal sheets in the production flow mode. This is followed by an intermediate category of cutters, whose representatives are devoid of an electric drive, but also have a massive active element in the form of a cutter and a frame, the presence of which unites suchmodels with first class planers.

Unless we are talking about complex operations that are planned to be performed in large volumes, then it makes sense to use compact and low-maintenance torches. These are manual guillotine shears, the device of which is maximally optimized for fast work with small workpieces. With this tool, you can cut a small metal sheet to the desired size, expend a little effort on it.

Technical arrangement of equipment

Again, the design and its characteristics are determined by the type of particular model. If we talk about machine tools, then their device is represented by a carrier platform, a work table, an electric motor, a clamping mechanism, as well as cutting knives that are set in motion after the activation of the power plant. Manual type guillotine shears for metal differ significantly. They also have two knives, one of which remains motionless even during operation, but the very principle of operation is based on muscular effort. The latest models also provide auxiliary mechanisms for sheet feeding and positioning. With the help of such devices, the operator can more accurately organize in-line processing of metal with different parameters.

Guillotine Shears Key Features

Performance is the main selection criterion for guillotine shears. One of the main parameters is the force with which the equipment and, in particular, the knife acts on the workpiece. So, the average value forpower load for machine models is about 5-7 kg/mm2. Further, the width and thickness with which the guillotine shears work are taken into account. The characteristics of the machine equipment allow cutting sheets with a thickness of 0.5 to 3 mm. In a hand tool, this figure rarely exceeds 2 mm. It matters in the workflow and the width of the cut. Depending on the model, this value can vary on average from 1000 to 1500 mm. The frequency of operations affects the overall performance of the guillotine and is usually around 60 cuts per minute.

Engine specifications

The operational capabilities of the guillotine machine are directly determined by the potential of the power plant, which provides the function of the knives. To begin with, it is necessary to subdivide the machines into models that operate on a network of 220 and 380 V. Power is the main indicator of the performance of the unit and is usually 3-4 kW. This potential makes it possible to confidently cope with thick sheets at high frequencies. By the way, the torque at which hydraulic guillotine shears operate can be 1200-1500 rpm. Here it is important to note the dependence of the electric motor on the design. So, the wider the cutting possibilities, the higher the power potential of the drive should be.

Technical specifications of the manual metal guillotine

The segment of manual guillotines for working with metal is mainly represented by saber-type units. At the coretheir design is based on a small panel or platform that holds the base, and the movable knife directly performs the cutting. As already noted, manual guillotine shears can serve sheets up to 2 mm thick. As a rule, in the case of stainless steel, this figure is 1.5-1.7 mm. However, aluminum sheets can be cut with such a tool even at a thickness exceeding 2 mm. True, the cutting length is still noticeably inferior to full-fledged machines - in standard families, the maximum reaches 1300 mm. On the other hand, such models benefit from their compact size and low weight, which rarely exceeds 100 kg. Accordingly, the manual guillotine can be carried around the job site to different points of assembly operations, which simplifies the production and construction process.

Consumables and accessories

In addition to guillotine equipment, manufacturers offer sets of processing tools, personal protective equipment and adjusting equipment. From the point of view of the main cutting operation, it is important to have high-quality diamond files on hand, which are most often used for locksmith operations with metal, as well as tiles and glass. These devices will help if the main work is performed by mechanical guillotine shears, which do not allow you to get a neat cut. In other words, needle files will allow you to make the edge better and smoother. Also, to adjust the guillotine machines, sets of appropriate keys should be provided. Usually, an all-metal bench square is used for this purpose. As for personal protective equipment, they must be in the equipment of the operator of the electrical machine. The basic set includes: gloves, filtering half mask, goggles and earmuffs.

Maintenance

It is mandatory for service personnel to check the reliability of fastening of the movable parts of the machine, the quality of the fixation of the bed, the correct location of the platform and the desktop. A properly installed and adjusted machine will ensure cutting with high precision and without deviations from the technical specifications. Special attention is paid to the electric motor that drives the guillotine shears and, in some models, is responsible for the automatic feeding of sheets. The condition of the oil, cooling systems and carbon brushes, if any, should be checked. Masters pay attention to the beam mechanisms that are involved in the transfer of torque. Clutches and gears must be in optimal working condition, otherwise the cutter function simply will not work.

Manufacturer Reviews

The segment of guillotine equipment is not as common as more technological and at the same time expensive devices for high-precision metal cutting. However, there is a choice. In particular, on the domestic market, these products are represented by the brands Stalex, Enkor, MetalMaster, etc. Under the Stalex brand, machine tools of good build quality that can handle hardbecame brands. This is largely due to the use of high-quality high-carbon cutters in the design of machine tools. In addition, the welded construction increases the reliability of the installation as a whole, and therefore the repair of Stalex guillotine shears is also delayed. As the users themselves note, only the sheet clamp mechanism and the system for limiting the depth of material supply will have to be restored after a long time of operation. As for the models from Enkor and MetalMaster, they are mainly represented by hand-held reciprocating cutters with a simple design and a convenient control mechanism. The only problem with the operation of such tools is the shortage of replaceable knives, which is what equipment owners most often complain about.

Conclusion

The main reason why mechanical cutters are still in demand is the combination of reliability, ease of handling and reasonable price. According to these indicators, guillotine shears are noticeably superior to alternative equipment made using modern technologies. But there are also disadvantages of the guillotine planer, which should be considered when choosing it. First of all, it concerns the quality of cutting. The fact is that only some models of manual modifications can provide an even and accurate cut - and even then, subject to the user having certain skills. Machine versions are mostly geared towards mass cutting large volumes of sheet metal, but don't count on them to provide a smooth edge.

Recommended:

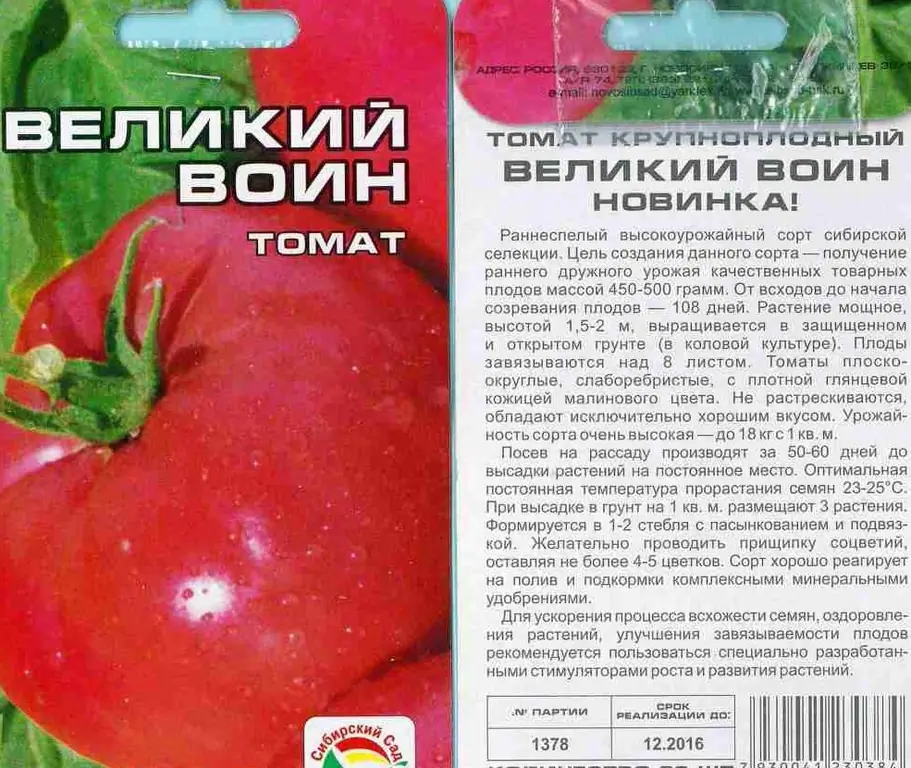

Tomato "great warrior": description, characteristics, reviews

The great warrior tomato variety was bred about ten years ago. During this period, it has become popular and in demand among lovers of large-fruited tomatoes. Its excellent taste qualities will not leave indifferent connoisseurs of this vegetable crop

The main object of commercial activity is the product. Classification and characteristics of goods

For an average person who is not related to business, the concept of an object of commercial activity is unfamiliar. However, this term indirectly applies to all spheres of our life. According to the theory, objects of this kind include everything that can be bought or sold, that is, property of any purpose, including goods. Let's find out what is meant by this concept. In addition, we will reveal the main characteristics of the product and its classification

Heat-treated wood: main characteristics, production technology, pros and cons

Almost every one of us has come across such a concept as heat-treated wood. However, few have thought about what it really means. Meanwhile, this material can be considered innovative. Due to the high temperature - from +150 °C to +250 °C - the material is strong and durable

Characteristics of the Su-35. Su-35 aircraft: specifications, photo of the fighter. Comparative characteristics of the Su-35 and F-22

In 2003, the Sukhoi Design Bureau began the second in line modernization of the Su-27 fighter to create the Su-35 aircraft. The characteristics achieved in the process of modernization make it possible to call it a 4++ generation fighter, which means that its capabilities are as close as possible to the PAK FA fifth generation aircraft

Hydraulic shears - an indispensable tool in construction

If you decide to do construction or, conversely, the demolition of old structures made of concrete, panels or metal, hydraulic shears will become your reliable assistant. This device will greatly simplify your work