2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:25

One of the key tasks when printing with a flexo machine is performed by an anilox - a shaft, due to which the ink is distributed over the target form of printing. Despite the outwardly simple device, this element is characterized by a complex principle of operation, the nuances of which are determined by the properties of its surface. To date, the anilox roll is produced in different versions, improving not only in structural, but also in functional qualities.

Anilox functions

The purpose of the shaft is one - to evenly transfer a layer of paint in the right amount with a verified dosage. An important characteristic of this process is the exposure of the layer parameters so that the paint does not stick together at the junction of the dots and does not smear due to redundancy. In modern printing equipment, the sufficiency of the volume of paint used when applied to the form is determined by the optical density,which is calculated by standard measurement methods. The optimal ratio is 1.55, which allows for high-quality reproduction of the full tonal range with the necessary contrast.

Design and manufacturing materials

As the name implies, the part has a cylindrical shape, which can be hollow or solid. A feature of the shaft is a cellular coating with honeycombs with a diameter of 2 to 25 microns on average. Today, special coatings are used to create the working surfaces of anilox, sometimes performed using the laser engraving technique. As for the materials of manufacture, the first aniloxes were rubber, after which they were replaced by metal counterparts with a chrome coating. Some modifications also use the copper plating technique, and a thin layer of nickel is used to protect the chrome surfaces. In any case, an important condition for the structural arrangement of an anilox roll is the presence of a porous structure on the surface.

To prevent rapid cell wear, many manufacturers are experimenting with spray formulations. In the competitive struggle, technologists from different companies strive to meet two requirements - the minimum layer thickness and high dynamic wear resistance, which implies protection against corrosion and accidental mechanical damage.

Anilox varieties

The main differences between different types of modern anilox roll are the way the surface is engraved. At the basic level, we can distinguish a mechanical methodformation of tetrahedral cells (clichograph) and laser models of formation of hexagonal honeycombs.

The use of tetrahedral pores due to the characteristic shape of the cells does not allow for increased ink transfer. In turn, the hexagonal honeycomb not only provides a volumetric transfer of paint, but also allows you to maintain a higher speed of the process. In many ways, this difference is due to the coatings of the two types of screen roller. The same chromium is more often used in the creation of square honeycombs, while ceramic aniloxes are formed using laser engraving. At the same time, it cannot be said that the hexagonal configuration is unambiguously more profitable in all cases. Depending on the characteristics of a particular model, the properties of absorbency, hardness and tension on the surface may vary, which also affects the quality of the final print result.

Anilox line

This indicator determines the number of cells on the area of one linear inch (12 lines, i.e. 2.54 cm). Usually it is calculated taking into account the angle of inclination of the cells relative to the axis of the cylinder. On average, it varies from 30° to 60°. Low line designs are more commonly used for varnishing and spot printing. The average lineature range of 165 to 300 lpi is typically used in coated rolls with a honeycomb volume of about 12 cm3/m2. For combined flexographic printing, it is appropriate to use high lineature up to 1200 lpi, at which the volume of cells will be 3see3/m2. As this indicator increases, the uniformity of the paint coating also increases. The more honeycombs, the better the ink transfer will be, although this rule is observed only if the shaft area corresponds to the print form, and the correct calculation of the cell parameters on the working area was initially performed.

Anilox cell volume

This value will depend on the useful capacity of the unit area of the working surface of the shaft. Usually, for numerical representations, the ratio sm3/m2 is used, although experts often use the BCM specification marking. It is important to bear in mind that the volume of a cell can increase not only through expansion, but also through deepening. The higher the capacity of the honeycombs, the more saturated the colors and the thicker the varnish layer - this is how the optical density of the plate increases proportionally. On the other hand, reducing the volume leads to an increase in the efficiency of the print job and an improvement in its quality. During the operation of the flexographic machine, the volume of honeycombs will decrease. This is a natural process due to wear of the coating, clogging of the cells with dirt, the appearance of defects, etc. To date, the following standardized cell volumes are used:

- 5, 4 cm3/m2 - used for vector design work.

- 3, 4 cm3/m2 - used in combined printing.

- 2, 3 cm3/m2 is the most advantageous format for process printing.

Many experts believethat for the user it is better to calculate the anilox by the volume of the cells, since it affects the result of the printing process to a greater extent. Despite the relationship between print quality and lineature, it does not always give an accurate idea of the optimal ink transfer formats, requiring many indirect parameters to be taken into account. Actually, the manufacturers themselves are guided by the principle of evaluating a suitable anilox roll for a flexo machine by the capacity of the coating cells, trying to diversify the size ranges of the working surface cells.

Print defects when using anilox

Incorrect use of dampening and inking rollers often results in flawed prints. The most common defects of this kind include:

- Fatting. The appearance of pronounced areas where the ink is perceived in the same way as printed fragments. This defect indicates insufficiently effective humidification. Problem areas occur in the center or along the edges of the form.

- Shading. Weak background relative to the uniform distribution of ink over the entire print area. Among the reasons for the formation of shadows are violations in the settings of the shaft.

- Stripe. Leaving dark or light streaks, which may be due to excessive contamination of the surface of the roller or ink misadjustment.

- Defects in paint transfer. Improper ink distribution in flexographic printing can cause gloss, barreling or even damage.surface.

- Template. This defect is known as doubling. The imprint rollers, if not properly adjusted, can cause duplication when printing.

Anilox roll care

Because the workflow of a flexo machine involves the use of many consumables in the form of wetting fluids, dyes, solvents and other chemicals, over time, functional surfaces become clogged and require cleaning. Surface cleaning not only reduces the risk of printing defects, but also extends the life of the roller. The simplest means of care include washing procedures using soft, non-abrasive brushes and chemical solutions.

Specialized Anilox Cleaning Methods

In professional use, anilox rolls are regularly cleaned using ultrasonic and laser methods. The first method involves the supply of ultrasonic waves in order to achieve the effect of cavitation, in which the smallest gas bubbles destroy foreign particles on the surface, but this method should be used with extreme caution, since excessive wave power can damage the cell structure. Laser cleaning is carried out with the help of special optical devices that provide sharp heating with strong vibrations on the shaft coating. In this way, even rolls with high linearity on ceramic coating can be cleaned without risk of damage.

New technologies

New trends in the manufacturing industryaniloxes are associated with their structural optimization and an increase in technical and operational parameters. In particular, lightweight modifications of rollers with high-strength plastic bases are appearing, spraying techniques with engraving are improving, and the resistance of surfaces to typical pollution is also increasing. The use of laser technologies in the manufacture of printing equipment expands its functionality. Combined devices are already appearing on the market today, which provide printing of a solid and a raster with a high exposure during the application of consumables.

Conclusion

Choosing the right anilox is not an easy task and requires a multifaceted analysis of the planned workflow. It is necessary to take into account not only the characteristics of the print itself, but also the working conditions, as this will reduce the cost of maintaining the device in the future. When selecting a design according to its protective properties, the operating temperature of the anilox roll is calculated in advance, which can vary from +50 °С to +150 °С on average. The composition of chemical consumables is also taken into account, among which there may be alcohol-containing solutions, varnishes, washing liquids with caustic soda, etc. All these data together allow us to understand which type of coated anilox will be the most profitable purchase in terms of operational and economic indicators.

Recommended:

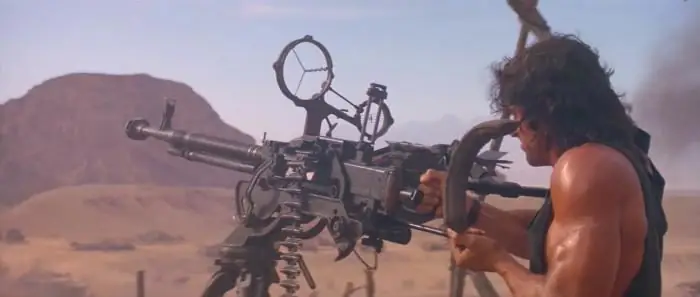

Machine-gun belt: types, purpose, charging

Cartridge belt is the main source of ammunition supply for machine guns and automatic cannons

Large-caliber machine guns of Russia and the world. Comparison of heavy machine guns

Even in the First World War, a fundamentally new and terrible weapon appeared on the battlefield. Large-caliber machine guns. In those years, there was no armor that could protect against them, and the shelters that were traditionally used by the infantry (made of earth and wood) generally made their way through with heavy bullets

Galvanized roll: description, specifications and reviews. Chain-link mesh galvanized in a roll

Galvanized coil is a long steel sheet that is used for various purposes. Galvanized steel is produced in this form of any parameters and sizes. Specifications define performance and areas of use

Roll mills: photo, description, characteristics, disadvantages and wear

In various sectors of the national economy and industry, the finest grinding of materials is required. These can be food enterprises, and factories of heavy industry, grinding coal with semi-anthracite and all kinds of waste. And in each case, the task is to provide technical support for this operation with minimal organizational costs. Such requests are met by a medium-speed roller mill, which combines optimal power and design characteristics

Vertical milling machine, its device and purpose

To date, it is quite typical to use parts of complex configuration in various branches of mechanical engineering - shaping surfaces of stamps, molds, gears, copiers and many others. The main methods for manufacturing such complex-shaped products are the following: casting, stamping and cutting