2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:26

Modern glue may vary in composition, scope, cost, etc. In any case, such a tool should be chosen, taking into account, first of all, the characteristics of the surfaces to be joined. For hot materials, for example, only heat-resistant adhesive should be used.

Types by composition

It is found today on sale both synthetic and natural heat-resistant glue. The first type of funds, among other things, contains in its composition various kinds of additives designed to give them special properties:

- moisture resistance;

- frost resistance;

- plasticity;

- fast drying ability, etc.

Such glue can be produced on the basis of polymers, monomers, oligomers. Also on sale today are compositions of this variety, made from combinations of such substances. The most heat-resistant glue - synthetic - is made on the basis of inorganic compounds. Some of these products can, for example, withstand temperatures up to 3000 ° C.

The main component of natural glue is sodium silicate inliquid glass solution. Also, the composition of such products may include, for example, fireclay fibers, sand, mineral additives.

Varieties by area of use

Heat-resistant glue can be used to connect a wide variety of materials. For example, there are varieties of them on sale today, designed for gluing dishes, metal, wooden or plastic components of various kinds of equipment, etc. But most often such glue is used today when laying stoves. At the same time, some varieties of compositions of this type are intended for the assembly of furnaces and pipes of such heating equipment. Other types of heat-resistant adhesive can be used for tiling stoves and fireplaces.

Another common type of such tools are designed to connect metal surfaces. Compositions of this type are collectively referred to as "cold welding". When choosing the means of the named variety, among other things, one should pay attention to what kind of metals they are intended for joining. Such glue can be supplied to the market in the form of both liquid formulations and mastics or pastes.

Clay masonry adhesive

Modern heat-resistant products designed for the construction of fireplaces and stoves can withstand temperatures up to 1000 °C. At the same time, one of their features is that they do not lose their properties even after repeated exposure to open fire.

In most cases, the products of this variety contain clay. Also the components of such glueusually are:

- cement;

- sand;

- chamotte fiber;

- various additives.

This type of glue is sold in the form of dry mixes. Before using for masonry, they are simply closed with water in the proportion indicated by the manufacturer.

Clay varieties of heat-resistant glue are very inexpensive. At the same time, they are most often used for laying solid fuel stoves.

Mixes for fireplaces with plasticizers

This glue belongs to the group of universal. It is supplied to the market both in the form of dry mixes and pastes. Most often they are used in this case for laying brick heating equipment. The composition of heat-resistant glue for ovens of this variety usually has the following:

- quartz sand as filler;

- aluminosilicate cement and kaolin as binding components;

- plasticizer - soapstone.

This glue is even more heat resistant than clay. Mixtures of this variety can withstand temperatures up to 1500 ° C. Soapstone glue is thus considered to be of better quality than clay. However, such compositions are much more expensive.

Fireproof tile adhesive heat resistant

For the lining of stoves and fireplaces, special types of bonding compounds are used. Most often, tiles on such heating equipment are fixed using glue based on aluminosilicates and kaolin. As binders in such a material withThis is usually done using white clay and cement. Also, the composition of products intended for lining furnaces includes in most cases:

- quartz sand;

- plasticizer in the form of liquid glass.

This glue is suitable for lining stoves and fireplaces not only with tiles, but also with porcelain stoneware. These types of products are relatively inexpensive. However, at the same time, they, unfortunately, do not differ in durability. Liquid glass, which is part of them, loses its plastic properties after about 20 years and begins to crumble.

The most popular brand of such a product at the moment is Terracotta among consumers. Heat-resistant glue from this manufacturer, judging by consumer reviews, is easy to use and simply excellent adhesive properties. The tile on such a paste lies flat and lasts for a long time. At the same time, Terracotta glue is relatively inexpensive.

What is heat resistant metal adhesive

Such compounds are usually synthetic. With their help, metals are most often glued. But if desired, the means of this variety can also be used to connect glass and ceramic materials. Sometimes this type of glue is also used in brickwork.

In most cases, the means intended for connecting metal elements are able to withstand temperatures up to 1000 ° C. But for some brands, this figure can be 3000°C. Metal assemblies bonded using heat-resistant agents of this variety can subsequently withstand even severe mechanical stress. The only drawback of heat-resistant glue for metal is that they cannot be used to glue bulky parts.

Instructions for use for clay mixtures

As already mentioned, this type of glue is most often used for laying stoves and fireplaces. Instructions for use for mixtures of this variety are quite simple. Such glue is made as follows:

- some part of the mixture is poured into a bucket or basin;

- thoroughly mix the ingredients;

- pour warm water into the basin in such quantity as to obtain a consistency convenient for masonry.

Use heat-resistant glue prepared by dissolving with water for fireplaces and stoves when laying in the standard way. Clay compositions are used so that the thickness of the joints in the masonry is 3-5 mm.

Instructions for use for tile adhesive

Such compositions are also quite easy to use. Mix a heat-resistant reinforced adhesive of this type, supplied to the market in the form of a dry mass, with water, according to the manufacturer's instructions. In some cases, a little water must also be added to the pasty products of this group (if they have dried up during storage). It is best to mix the compositions of this variety using a drill. The finished mass should be as homogeneous as possible. Before use, solutions are usuallyincubated for 10-15 minutes. before swelling. Then they are mixed again.

At the same time, as in the case of heat-resistant clay mixtures, small portions of such glue are prepared. Tile heat-resistant compounds seize quickly after adding water. In any case, the prepared portion must be used within a maximum of 30 minutes.

Before applying heat-resistant glue, the surface of the stove or fireplace is thoroughly cleaned of dust, old plaster, etc. Next:

- apply glue to the tile over its entire surface with a spatula;

- keep the tile in a horizontal position for 2-3 minutes;

- press the finishing material to the surface of the oven and hold it in this position for several seconds.

If the tile used for finishing is large, it is recommended to apply glue not only on it, but also on the surface of the furnace itself. It is this instruction for use that is provided, for example, for heat-resistant reinforced adhesive "Terracotta".

Recommendations from experts

It is allowed to start operating stoves laid out or lined with heat-resistant compositions no earlier than 2 weeks after completion of work. The heat-resistant composition must necessarily gain sufficient strength before heating. If the stove is flooded too early, microcracks will certainly appear in its masonry, through which smoke will subsequently enter the room. The tile from the fireplace heated up ahead of time after a while will simply fall off.

Instructions forapplication to metal adhesive

How to use the modern formulations of this variety? Instructions for use for heat-resistant mastic glue or liquid formulations of this variety are usually provided as follows:

- working surfaces are prepared by cleaning from dust and dirt;

- metal is drying;

- glue is applied immediately to both parts with a layer of 1-2 mm;

- details are fixed together.

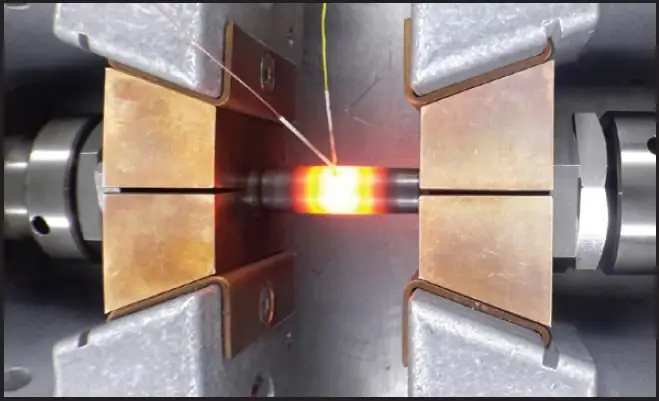

Metal bonding with modern heat-resistant compounds usually lasts about an hour. At the final stage, the unit connected in this way is most often additionally heated to 50-100 ° C, for example, in a heating cabinet. The time of such hardening depends on the particular brand of glue.

Recommended:

Latex glue: description, composition, characteristics, application

Today, many different compounds are used in order to glue different surfaces, materials, etc. One of the fairly common compounds is latex glue. The main advantage is that, depending on the changes in the composition, the scope also changes

Heat energy tariff: calculation and regulation. Heat energy meter

Who approves and regulates heat tariffs? The main factors affecting the cost of the service, specific figures, the trend of increasing cost. Thermal energy meters and self-calculation of the cost of the service. Prospects for billing. Varieties of tariffs for organizations and citizens. Calculation of REC tariffs, documentation required for this

Heat resistance and heat resistance are important characteristics of steels

Ordinary structural steels, when heated, abruptly change their mechanical and physical properties, begin to actively oxidize and form scale, which is completely unacceptable and creates a threat of failure of the entire assembly, and possibly a serious accident. To work at elevated temperatures, materials engineers, with the help of metallurgists, created a number of special steels and alloys. This article gives a brief description of them

Flux for welding: purpose, types of welding, flux composition, rules of use, GOST requirements, pros and cons of application

The quality of the weld is determined not only by the ability of the master to organize the arc correctly, but also by the special protection of the working area from external influences. The main enemy on the way to creating a strong and durable metal connection is the natural air environment. The weld is isolated from oxygen by a flux for welding, but this is not only its task

What is CAS: fertilizer composition, types, release form, purpose and instructions for use

What is CAS? In order for garden and agricultural crops to develop well and give large yields, it is necessary, among other things, to use nitrogen fertilizers. The most popular type of such top dressing is CAS