2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:31

PVC of the usual type are sheets that have a porous structure with a rough surface and a matte finish. If PVC is foamed, it is possible to obtain a tear-resistant and hard-feeling material with a smooth glossy surface, having a sandwich structure. Its inner layer will be porous, but the texture will remain uniform.

PVC foam production

In order to foam PVC and format the product from it, production lines are used, consisting of equipment such as an extruder, dies of the necessary calibrators, a cooler, a receiving device and a device that prepares the product for storage. Despite the fact that this production is complex in terms of physical and chemical indicators, the entire technological process takes place in a small, clean and tidy workshop.

The main raw materials in the form of loose mixtures and granules are delivered in plastic bags. On a small raw material site, stainless steel vats with stirrers are installed, into which it is poured,water is added. This is how the process begins, as a result of which foamed PVC will be obtained. Its production at first glance is very simple. Aged in vats for a day, the polymer component interacts with each other, matures, reaches the consistency of a molten mass and is fed into the receiving compartment of the extruder, which should foam the PVC with high quality.

Depending on the productivity of the enterprise, the extruder can be with one or two working screws. Specialists prefer installations with two screws. In them, the molten mass flows in parallel flows, so the temperature remains unchanged for longer, which allows foaming PVC evenly and without effort to achieve the required density in the product.

Screws convey the plastic mass for extrusion. Here (due to excess pressure) it is possible to foam the PVC, and then squeeze it out of the extruder through the holes that give the product volume and shape. Formed profiles, pipes, sheets, films enter the receiving table, from where they are fed onto a moving conveyor belt and are simultaneously cooled.

Cutting and decorating

For cutting PVC products, circular saws are used, equipped with a vacuum cleaner and a collector for fragments. Cutting of products is carried out at high speed. Then a decorative pattern can be applied to the surface. To do this, the process chain includes grainer machines that print images and markings directly on the PVC product. Decorative coating can imitate marble chips, plaster, have other typesclearance.

What is valued and where is it used?

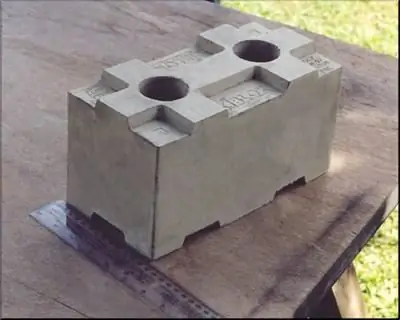

Very valuable qualities such as strength, lightness and fine-mesh structure, which has foamed PVC. The photo attached to this article clearly demonstrates them using a pipe as an example. The porosity is clearly visible on the section, and this despite the fact that the surface of the product is shiny and smooth.

Resistance to external weather and climatic factors, chemical-physical interactions and corrosion has widely opened the door for this material to be used in construction, advertising business, agriculture, thermal power engineering, oil and gas and chemical industries, in everyday life.

Recommended:

Foam block: foam block dimensions, history of appearance and application prospects

Each movement of the bricklayer is performed at a certain speed. An ordinary clay brick weighing about 3 kg or a large foam block of the same mass will be installed in the wall in the same time. But the dimensions of the foam block are eight or even twelve times the size of a brick, which dramatically increases the speed of masonry. Another important advantage of a light and warm building material is that it requires an adhesive rather than a complex cement-sand mortar

UEC - what is it? Universal electronic card: why you need it, where to get it and how to use it

Surely, everyone has already heard that there is such a thing as a universal electronic card (UEC). Unfortunately, not everyone knows the meaning and purpose of this card. So let's talk about UEC - what is it and why is it needed

What you need to work in a taxi: necessary documents and requirements, regulations and legal aspects. Feedback and advice from taxi drivers, customers and dispatchers

According to many passengers, the job of a taxi driver is the easiest. You sit, listen to pleasant music and drive back and forth. And they give you money for it. But this is only the outer side of the coin. The reverse is much less rosy. We will talk about it in this article. And we will also highlight what you need to work in a taxi

The first investment voucher fund: how to get dividends and what you need for this

Many donated vouchers to the First Investment Voucher Fund. How to receive dividends in this organization? All this will be said in the article

Modern durable and high quality material G10: description, properties and application

People have been using knives as household tools for a very long time. With the passage of time and the improvement of technology, more and more new substances were used to create this tool. To date, the G10 material has become a new word in the creation of these things