2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Working with metals has been done by people for a very long time. Mankind uses a variety of types of metals to produce functional and decorative items, creates various alloys that have characteristics other than the original material.

This article will focus on one of the most common metal materials today - copper. You will learn what this material is, and also get acquainted with what is now most often made from it. Most likely, you have already heard about such a thing as a copper plate, and its uniqueness lies in the fact that it can be used in medicine, in production, and also for creating jewelry. Naturally, this is not the only form factor - the rest will also be discussed in this article. So if you are interested in how a copper plate is created and used, as well as other objects made of copper, then this material is for you. You will find here all the basic information about the production and use of objects made of this metal, as well as their characteristics.

What is copper?

So, before you start learning what a copper plate is, as well as tape and foil, you should figure out if you know everything thatnecessary, about copper. Many people do not think about such simple details, assuming that they do not need much information on a particular topic. It's the same with copper - most people can say that copper pipes exist, and that there was a copper age in ancient times, but they can't give any details about the metal itself. That is why you need to pay more attention to the metal itself before taking on the study of products made from it.

Where to start? You should understand that copper is a pure metal, not an alloy, so it can be found in nature. And precisely due to the fact that, in principle, it is not so difficult to detect it, the Copper Age happened, which in ancient times replaced the Stone Age. The fact is that copper tools were much more efficient than stone counterparts, and in combination with a large amount of copper ore and its low melting point, very efficient production was obtained.

Of course, even then the main problems were noticeable, namely the softness of this material. If not for this, then perhaps humanity would never have entered the Iron Age. But iron replaced copper because it was much harder than copper.

However, in the modern world, copper is used very widely, it is one of the most popular metals in production. But it is very important that the material is pure, without impurities of other metals, since even a hundredth of a percent of the content of other materials in copper greatly reduces its qualities of thermal and electrical conductivity, for which it is sohighly praised and because of which she is so popular.

Well, now you know the basic data regarding the metal itself. It's time to move on to more specific issues, namely the products that are made from it. Naturally, absolutely all types of copper products will not be described here - there are a lot of them. Therefore, it is immediately worth noting that attention in this article will be focused on plates, tapes and foil. And the first thing that will be considered in detail is the copper plate.

Copper plate production

When copper is obtained from copper ore, it must be given a specific shape, which is necessary for the further use of the material. And most often this metal is rolled into a copper sheet, from which a plate of the desired shape is already created. The size and thickness of the copper plate depends on what the elements that are created from it will be used for. Very often you can find plates with a thickness of one millimeter, most likely, they are the most common of all. As you already understood, copper plates are produced using a special machine that can roll the metal to the desired thickness. This is a high-tech machine, so you can rarely find it in private use. More often, such devices are located in factories and factories working with non-ferrous metals. So, you have a copper sheet. What can be done with it? What are its characteristics?

Copper plate specifications

Can you imagine what a 1mm thick copper plate looks like? It's prettya thin object, and therefore, first of all, we can safely talk about the flexibility of this material as a leading characteristic. Combined with its high strength, the flexibility of the copper plate makes it suitable for a wide range of applications, but more on that later.

Now it is worth noting that the copper plate has other very important properties that also attract people who use this material for their own purposes. It turns out that copper is one of the best conductors of electricity and heat among metals - in these parameters, the material is second only to silver. However, it is immediately worth noting that the cost of copper is significantly lower than the cost of silver, which is classified as a precious metal, so the choice for industry and production is obvious.

In addition, more than one study has already confirmed that copper is a kind of medicine, so the characteristics of this metal in general are amazing. After all, this material can be used not only as copper rolled products in production, but also as a medicine at home. Well, it's time to take a closer look at the applications of copper plates.

Application of copper plate

Size, weight of the copper plate (it can be easily calculated by the formula: length (cm) × width (cm) × thickness (cm) × 8.93 (specific gravity of copper, g/cm3)), as well as some other physical and technical factors, can influence the industry for which the material is made.

First of all it is worthpay attention to production, especially to the non-ferrous metal industry, because it is there that these materials are most often produced and used. There, copper plates are welded, their shape is changed, cut to the desired size and shape, and so on. As everyone is well aware, copper plates have been used for a long time to create a variety of pipelines. However, apart from this example of the beneficial use of copper, there are other areas that many people do not think about.

For example, copper plates are widely used for making various decorative ornaments. The fact is that the flexibility of copper is used to depict various pictures on it, even the most detailed ones. This makes jewelry to hang on the wall in the house, or to wear on your own body.

By the way, if we talk about the body, we must not forget that small copper plates are made in order to use them for medicinal purposes. Copper has healing properties, so if you use these plates, you can not only feel better, but even recover from some diseases.

Copper plates are also used for chips, which are then used in high-tech products such as computers. Here, the high electrical conductivity of this metal is very useful, as well as the possibility of giving it any shape with a minimum thickness. You can often find such elements on motherboards, video cards, and so on. It must also not be forgotten thata copper plate is used for grounding, again due to its ability to conduct electricity. Enough talking about the plate, though, it's time to look at other elements as well.

Copper tape production

In principle, copper tape is produced in much the same way as plate, but it is worth noting that even more advanced equipment is required here to achieve increased accuracy. Unlike a conventional plate, which can be created using hot-rolled technology, it is precisely cold-rolled technology that is needed for the production of a strip - it is through its use that it is possible to achieve the required thickness of the product. How thick should the copper tape be? You will find out about this now. You should pay attention to the fact that both the production and characteristics of different types of copper products may be the same or very similar, but their applications may already be very different.

Copper tape specifications

Copper tape, also known as copper strip, differs from plate mainly in its thickness. If for a plate a thickness of one millimeter is practically the minimum (basically, plates are much thicker, especially when the final product must be durable, that is, used in business, and not for decoration), then for a tape such a thickness is already a practically acceptable maximum. The fact is that the thickness of the tape is usually about one tenth of a millimeter, sometimes it can even reach five hundredths of a millimeter. That is why copper tape is not supplied in sheets, like plates, but in rolls, as it is rolled up. As for the other parameters, both thermal conductivity and electrical conductivity do not change due to changes in the thickness of the material.

Application of copper tape

One of the main areas of use of copper tape is the production of a variety of heat exchange devices, just because all the necessary properties of the metal are preserved, regardless of its size and thickness. Also, copper tape can be found in a variety of power capacitors, transformer elements, and even in building materials. But then again, these are all practical ways to use it, and in recent years, more and more various decorative works have begun to appear, in the creation of which copper ribbons are used.

Copper foil production

The last material to be considered is copper foil, the thinnest copper used in the industry. However, do not rush to say that you have seen and know it, and also constantly use it. The fact is that food foil, so popular in the household, is most often made of aluminum or steel, but not copper. As far as copper foil is concerned, it can be produced in two ways - the result is either rolled or electrodeposited foil. In the second case, the material turns out to be grainy, so it cannot be used dynamically - such foil is used only for static purposes. As for the katana, this foilis much smoother, so its dynamic use does not threaten the appearance of cracks.

Copper foil specifications

Copper foil, as mentioned earlier, has all the same properties and characteristics as the previous material options, but differs in its incredibly small thickness. If it seemed to you that the copper tape is very thin, then you were mistaken - in fact, the foil is the thinnest one. With certain processing methods, it is possible to achieve an amazing thickness of only 18 micrometers, and in some cases the result is even more impressive. But how can such a thin material be used?

Copper foil application

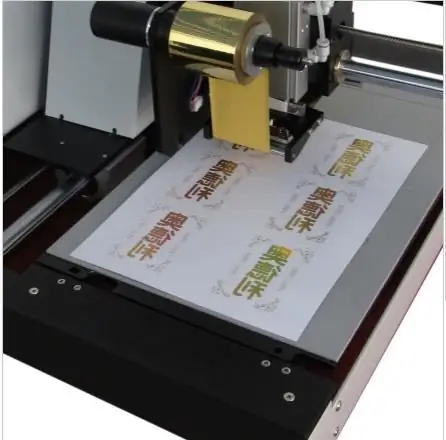

Naturally, due to its electrical conductivity and incredibly thin thickness, copper foil is very often used in electrical engineering. It can be found in various electronic boards, even the tiniest ones. It is also very common to see copper foil being used for cable shielding, a task far superior to any other material available at the same price point. As mentioned earlier, copper foil is not used in the food industry, as it has much more suitable aluminum and steel alternatives. You can also find copper foil in the construction industry - most often there it is used for thermal insulation. And of course, very often not only copper, but also any other foil is used in printing in order to produce embossing.

Of course, these are not all areas in which such a wonderful product as copper foil can be used. Many thousands of years ago, when there was a copper age on Earth, people did not know how to handle other metals, so they used a simple and common material - copper. It, for all its shortcomings, was much better at making and using tools than the stone that had been used before.

Now humanity has access to a wide variety of materials. However, people still continue to use copper, which is proved by the fact that its incredible properties and qualities have been appreciated, appreciated and will be appreciated at all times.

Recommended:

Niobium foil: production and application

Not all elements of the periodic table received their own cells immediately after opening. For example, niobium. It was discovered in 1800, but recognized after 150 years. In the industry, niobium foil has occupied a certain niche and strengthened itself in it, since it has useful characteristics. Its potential is revealed when used as a raw material for the creation of alloys, solutions and chemical mixtures

Foil stamping at home. Cold and hot foil stamping

In order to make a gift or souvenir original and unusual, such an operation as foil stamping is often used. Also, using this printing technology, “wearable” leather items are often decorated, logos are applied to branded products, advertising panels are made, etc. If you wish, you can do embossing with thin metal yourself

Tinned copper: concept, composition, manufacture, characteristics and application

Tinning means to cover metal products with a thin layer of tin, which in turn prevents the process of oxidation of metal surfaces. But if we take into account the maintenance of the soldering iron, then the process is slightly different

Copper powder: production, purpose and application

Copper powder is a product widely used in the paint and varnish, chemical, automotive, instrument making, and nanotechnologies industries. There are several main brands of such a product. And all of them are produced in accordance with the standards stipulated by GOST

Duralumin is a high-strength aluminum-based alloy with additions of copper, magnesium and manganese: properties, production and application

What is duralumin? What are the features of duralumin alloy? Technical and quality indicators of the alloy. A variety of products from this metal and their scope