2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:30

Not all elements of the periodic table received their own cells immediately after opening. For example, niobium. It was discovered in 1800, but recognized after 150 years. In the industry, niobium foil has occupied a certain niche and strengthened itself in it, since it has useful characteristics. Its potential is revealed when used as a raw material for the creation of alloys, solutions and chemical mixtures.

Niobium mining

1 ton of ore contains only 24 g of pure element. Therefore, the enrichment of raw materials is considered a costly and complex technological process. The main deposits of niobium are in Canada, Brazil, Australia and several African countries.

In natural conditions, the element occurs in a diffuse form. Basically, niobium "lives" in igneous rock and various crystals. Some minerals contain a small percentage of the element: pyrochlore, tantalite, loparite.

Niobium foil is in great demand. The production of the main element is divided into 3 stages:

- detection of ore with a high percentage of niobium and its constituents;

- separation of the desired element and tantalum, with which they have similar properties;

- purification of metal and alloys from impurities and their recovery.

The main production components are:

- aluminum;

- sodium;

- carbon;

- high temperature.

Features

Many industries are adopting this metal. Rolled products, including niobium foil, facilitate the process of introducing the main chemical element into the base compositions. Throughout the technological process, niobium carbide is used, which can change the properties of metals and positively affect their characteristics.

The virtues of this substance are called:

- refractory;

- corrosion resistance;

- improving the heat resistance of substances and their conductive ability.

Alloying 1 ton of steel requires only 200 g of active ingredient. Niobium foil in the process of processing improves the characteristics of the finished product. Similar steel is distinguished by:

- increased hardness;

- plasticity;

- improved corrosion resistance;

- reduced brittleness.

Niobium is able to protect non-ferrous metals from the negative effects of acids and alkalis. When creating various devices and structures, this metal is used,thanks to its protective properties.

Metal use and manufactured products

Niobium foil is generally used for alloying non-ferrous and ferrous alloys.

Main industries where the specified chemical element is used:

- space technology;

- aerospace engineering;

- electronics and radio engineering;

- chemical apparatus engineering.

The uniqueness of the niobium band lies in the absence of interaction of matter with uranium at temperatures below 1000 °C.

Positive characteristics allow the use of niobium to protect a nuclear reactor. The element also lowers the resistance of the conductor to obtain cryotrons.

Therefore, the main "employee" of the nuclear industry is niobium foil. Using it allows you to create containers for liquid and radioactive metals.

Recommended:

Modern production. The structure of modern production. Problems of modern production

Developed industry and a high level of the country's economy are key factors influencing the we alth and well-being of its population. Such a state has great economic opportunities and potential. A significant component of the economy of many countries is the production

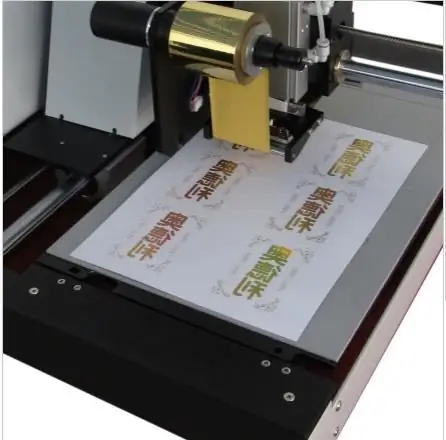

Foil stamping at home. Cold and hot foil stamping

In order to make a gift or souvenir original and unusual, such an operation as foil stamping is often used. Also, using this printing technology, “wearable” leather items are often decorated, logos are applied to branded products, advertising panels are made, etc. If you wish, you can do embossing with thin metal yourself

Copper plate, foil, tape: production, characteristics, application

Copper is one of the most popular metals in the world today, it is used in many areas of production

Use of niobium. Niobium production in Russia

At present, with the development of industry, there is a need for more and more quality materials. One of these is niobium. The use of this substance is not very widespread, but only because the price for it is quite high. However, this substance has excellent characteristics

Niobium strip: production, properties, application

Niobium is a chemical element with 41 serial numbers. It was first discovered at the beginning of the 19th century, but its recognition was delayed by 150 years. Only in 1950, by the decision of the International Union of Applied and Theoretical Chemistry, the atom was allocated its own cell in the periodic system of Mendeleev