2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:38

Tube bending is a fairly common procedure. But for its implementation, you need a special device. You can make a pipe bender with your own hands or purchase it in a store.

Serial devices can be classified according to several factors, such as how they work. They have different types of drive, but to work on any of them requires a certain experience. The prevalence of such devices is limited by their high cost. An excellent solution would be to make the device yourself, during which you can use available tools.

Preparation of materials

In order to make a pipe bending machine with your own hands, you must select a design. It can be frontal, which provides for the presence of:

- three rollers;

- axis of rotation;

- drive chain;

- metal profile.

The rollers will act as shafts, and they will be made of metal. At the base -a mechanism that will set all the elements in motion. As for the metal profiles, they will form the basis of the structure frame.

You can make a pipe bender that will have polyurethane or wood rollers. These materials do not have such high strength, so they will be subjected to bending. Such a device will not last so long, it simply cannot withstand the loads.

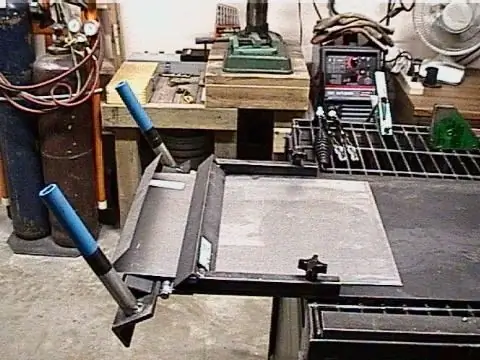

The pipe bender will use the principle of rolling or rolling, each of which minimizes the possibility of damage or breakage of the pipe. In order to make a bend, it is necessary to insert the product between the rollers and turn the handle. Such a simple device will allow you to get bends that will correspond to certain parameters.

In addition to the above items, you should prepare:

- jack;

- spring drive chain;

- metal shelves;

Springs should be of high strength, and shafts should be prepared in the amount of three pieces.

Production process

If you decide to make a manual pipe bender, you will need to make a reliable frame. Its elements are connected by bolts or welding. Next, an axis of rotation and shafts are installed, two of which will be located above the third. The distance between the axes of the shafts will determine the radius of the bend.

In order to actuate the mechanism, a chain drive is used. To complete it, it is equipped with three gears, while the chain itselfcan be borrowed from an old car or motorcycle. A homemade pipe bending machine provides for a handle on the structure. It will connect to one of the shafts. Due to it, a torsional force is created.

Product assembly

On the pressure shaft, it is necessary to fix the gears, rings and bearings, which are connected by keys. It is better to entrust the turning of rollers to a specialist. One of the shafts will be suspended on a spring, while the other two should be placed on the sides.

Holes are drilled in the rings, which are necessary for threading and making grooves. A homemade pipe bending machine will have a shelf that is made from a channel. Holes are drilled in it, and then threads are cut, which is necessary to install the pressure roller.

The structure should be assembled by welding or bolts. The frame is mounted first, which will act as legs. The next step is to hang the shelf. Shafts are pre-fixed to it, for which springs should be used. Side support shafts are installed on a home-made pipe bender, on one of which a handle is fixed. The pipe bender will also have a jack. It is installed at the last stage.

Mounting the pressure roller and tensioning the chain

The pressure roller must be secured with the keys. Then it is screwed to the shelf. Installation of this part is carried out according to a certain algorithm. It provides for the installation of a shaft on a shelf, to which nuts are pre-welded forsprings.

After that, the shelf is turned over and suspended. The chain tension should be carried out using a magnetic corner, which will act as a holder.

Assembly Tips

The tube bender will have sprockets that use keys to drive. They are pre-made from the grower. The drive handle will have a swivel tube to help install the jack. For this, the same welding is used, but you can also resort to bolting.

Production of hydraulic pipe bender

Hydraulic type tube bender will provide:

- pipe stops;

- hydraulic cylinder;

- plank;

- injector.

Additionally, prepare:

- hydraulic jack;

- channel;

- shoe;

- metal plates;

- three videos.

Work technology

The channel structure is assembled first, which should be supplemented with rollers and a shoe. From a similar material you need to assemble the frame. The platform will need to be reinforced with metal plates. A jack is to be installed on the shelf.

The structure is fixed with bolts. The rollers will be located at the same height in a rectangular channel. The shoe is installed below. These elements will determine the bend radius of the pipe.

To use bythe purpose of the hydraulic pipe bender, you will need to insert the pipe into the shoe and secure on both sides. Next comes the jack, its handle must be slowly rotated. The force generated by the drive will be transferred to the roller, and the pipe will begin to bend at a certain angle.

Instead of a conclusion

In the manufacture of greenhouses, greenhouses, fences and arches, it is quite often necessary to bend a metal pipe. It is used to form furniture frames and other structures.

You can solve this problem with the help of a special pipe bender, but not everyone can purchase its factory version. Home craftsmen and many professionals make such devices on their own. Their main part is a hydraulic cylinder, which performs a power function.

Recommended:

Semiautomatic welding machines: rating, pros and cons of the best machines

We present to your attention the rating of the best semi-automatic welding machines. The list includes the most popular and most intelligent models that can be found on the domestic market. Consider the remarkable characteristics of the devices, as well as their pros and cons

Machines for fertilization. Classification of machines, methods of fertilization

Fertiliser machines are designed to replace human manual labor in this operation. In relation to mineral fertilizers, spreaders and seeders with fertilizer seeders are used. Aggregates are also used for making those in liquid form

Bending machines: types, description, principle of operation

Bending machine: description, specifications, features, principle of operation, photo. Edge bending machines: varieties, device, design, parameters, manufacturers. Manual and rotary hemming machines: what's the difference?

Pipe bending: technology description, features and methods

A plastic pipe is a PVC product with a reinforcing layer inside. Thanks to the rapid development of modern technology, such materials quickly replaced heavy and bulky cast iron pipes from the construction industry. Therefore, at home, when arranging underfloor heating and installing a water supply system, the question often arises of how to bend pipes. You will find a description of the technology, features and methods of working with PVC pipes in our article

Bending machines: types, description of designs, characteristics, settings

Bending machines: types, design features, application, photo. Description of machines, technical characteristics, settings, modifications