2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:43

The lighting system at a production facility is a complex complex that combines a whole group of devices that are distinguished by reliability, durability and functionality. Each individual component of this system is a device in the form of a light source, which also has special requirements in terms of energy consumption. Moreover, this applies to devices located indoors, and to external lighting, which often performs a decorative function. At the same time, an industrial luminaire must meet the requirements of ergonomics, that is, not to tire the eyes and meet the modern level of comfort in operation.

Purpose of industrial lamps

Industrial lighting sources have a lot of differences from domestic household counterparts, but in most cases they solve the same problems. The first is room lighting. Moreover, special requirements are imposed on industrial light in terms of brightness indicators, since employees can be in the created conditions for several hours a day. By the way, in the regulations relating to compliance with working conditions, a separate section is devoted to the rulesorganization of industrial lighting. In addition, luminaires for industrial premises can perform the tasks of technological and emergency lighting. A separate group is decorative street lighting devices. In terms of power and protection requirements, they are on par with industrial and commercial devices, so they are often considered in the same segment. With the help of such devices, park areas, playgrounds, stadiums and highways are served.

Features of industrial luminaires

Features of the lamps themselves largely follow from the mentioned requirements for them. First of all, it should be a physically reliable device that meets the strength and durability indicators. Basically, the fulfillment of this condition is assigned to the body. Typically, high-strength plastics are used in the manufacture of commercial models, as well as composite elements. In industrial models of cases, metal is more often used. Another thing is that they mean special alloys that do not weigh down the overall design with the lamp. Moreover, different types of industrial luminaires, from the simplest spotlights to panel ones, may also require external provision with a special frame device. Metal gratings are usually used to protect not only the lamp, but also the body itself from damage. Such solutions are usually practiced in factories, plants and combines, where there is a risk of mechanical damage to the light source.

The features of industrial lighting include some operationalquality. Of course, to provide large rooms with light, a component of the appropriate power is needed, which is capable of operating for a long time without updating. For example, industrial ceiling lamps based on LED lamps can be operated for about 40-50 thousand hours. Now it is worth considering in more detail the characteristics of such devices.

The main characteristics of fixtures

The nature of the lamp is mainly determined by two parameters - the power and strength of the luminous flux, measured in Lumens (Lm). With regards to power, it has already been said that in the case of industrial devices, they have more potential. For example, the initial level is in the spectrum of 25-40 watts. This is enough to serve the average office space. For corridors, halls and work sites, panel lighting segments are usually purchased, in which there are 70-90 W lamps. Models with high power are also used for street lighting of areas, although these tasks are more often entrusted to floodlights with an even more impressive return of up to 500 watts. For models placed indoors, the characteristic of the luminous flux is also important. For example, industrial ceiling lamps from the middle segment can provide 3.5-4 thousand lm. Accordingly, this model is more suitable for work in a small office space or studio. But to illuminate a large room, workshop or hall, you will need a device of at least 6 thousand lm. By the way, some enterprises use several lighting points, the luminous flux of which reaches 8-9 thousand lm.

Classification by design type

The most common ceiling, pendant and wall industrial lighting fixtures. Traditional ceiling-mounted ones are convenient because, as a rule, they do not occupy free space and make it possible to scatter radiation over the entire area of \u200b\u200bthe room as profitably as possible. Usually these are industrial fluorescent lamps, which have a standard mounting method and are inexpensive. In other words, this is a standard and even familiar solution. But in some cases it makes sense to turn to wall models. These are devices that are fastened with screws, brackets and anchor connections to the wall. This option justifies itself when it comes to a room with low ceilings. Quite original proposals are increasingly appearing on the market in the form of floor lamps. They are essentially tripod lights that are used on construction sites, manufacturing facilities, and when performing rescue or emergency operations.

Classification by security type

In the markings of fixtures, you can find the designation IP, next to which there is a number indicating the security class of a particular device. It has already been said that for an industrial lamp the level of protection is fundamentally significant, so the choice should be based on this marking. So, the IP20 base class represents luminaires that can be used in relatively safe and clean places - for example, in offices, warehouses, offices, etc. Morewe can note the IP23 class, which indicates that these products can already be installed in unheated rooms, as well as outdoors, subject to basic external protection. If you need an industrial luminaire suitable for full-fledged outdoor use with exposure to splashes, dust and rain, then you should turn to devices that are marked IP43. The most resistant models are available under the IP67 class and above. These are devices that are moisture and shock resistant, not afraid of high temperatures and have a long working life.

Classification by lamp type

Despite the development of lighting technology, there are not so many fundamentally new devices. There is only one type of lamp that today opposes traditional solutions. These are LED lamps that compare favorably with obsolete counterparts due to a higher resource, low power consumption, decent radiation properties with optimal brightness, etc. But there is also an unpleasant minus that distinguishes industrial LED lamps even in budget versions - this is a considerable price tag. Some competition for LEDs in terms of performance can be made by fluorescent and halogen lamps. The former are suitable for public, administrative buildings and facade maintenance, while the latter are more likely to be oriented towards office and small industrial premises. Do not leave the industrial segment and incandescent lamps. However, high power consumption and low operating life still forces many managers to switch to moretechnological options for light sources.

Installation nuances

In choosing the method of installing the lamp, everything depends on its design. It is important to foresee fittings suitable for fixing in advance if a non-standard fastening technique is planned. But in most cases, industrial wall lamps are mounted on brackets or tightly fixed with anchors. Difficulties usually cause only point models. The fact is that they are not just attached to the surface, but are carried through the ceiling niche, penetrating into the hidden space. To do this, you need to make a hole in the panel, mount the case in the frame power base of the subceiling space and make an electrical connection.

Producers

As the practice of using various lamps shows, imported products are the most reliable. The budget segment is represented by Unitel and Glanzen, and if financial capabilities allow, then you can safely purchase LEDs from Osram and Philips. As for domestic manufacturers, it is better to choose an industrial lamp from the families of the Svetozar and ERA companies. Perhaps, in terms of color rendering, they are inferior to foreign counterparts, but in terms of reliability they demonstrate quite a decent level.

Question of price

The most affordable lamp models are estimated at 50-100 rubles. In this segment, you can find halogen models, incandescent lamps andsome energy saving options. LED models cost 300-400 rubles. At the same time, it is advisable to immediately purchase a housing industrial lamp, which can cost about 800-1000 rubles. in budget performance. Such a kit is more profitable to purchase than a separate lamp and housing.

How to choose the best lamp option?

Although commercial and industrial models are defined by the same requirements, including high brightness, reliable housing and careful power consumption, after all, each case is individual. For example, in an open area for temporary use, it is worth buying floor spotlights with a high protection class. To ensure a large production workshop, it makes sense to look after industrial dome luminaires with a low level of external protection. The fact is that for premises, additional costs for the security of the device may be unnecessary, but you should not save on soft radiation that is gentle on the eyes of employees.

Conclusion

Often, the question of saving the cost of maintaining enterprises is the key when choosing engineering and communication equipment. The lighting system in this regard is one of the most expensive. And the transition to LED sources allowed us to solve a lot of financial problems. Suffice it to say that industrial lighting and luminaires based on Led technology are distinguished not only by balanced energy consumption, but also by a high working life. In practice, these advantages provide a doubleadvantage over traditional lamps. However, there are advantages to more familiar lighting technology. So, incandescent lamps and halogen devices still differ in radiation that is more comfortable for the eye, so the choice in favor of new technologies is not always obvious.

Recommended:

Beet harvesters: types, purpose, characteristics

Beet harvesters are machines used for harvesting sugar beets. This technique digs up the roots of the beets, selects them from the soil, cuts the tops, collects everything in bunkers or loads the roots into a nearby moving vehicle, and the tops into a tractor cart hitched to a beet harvester

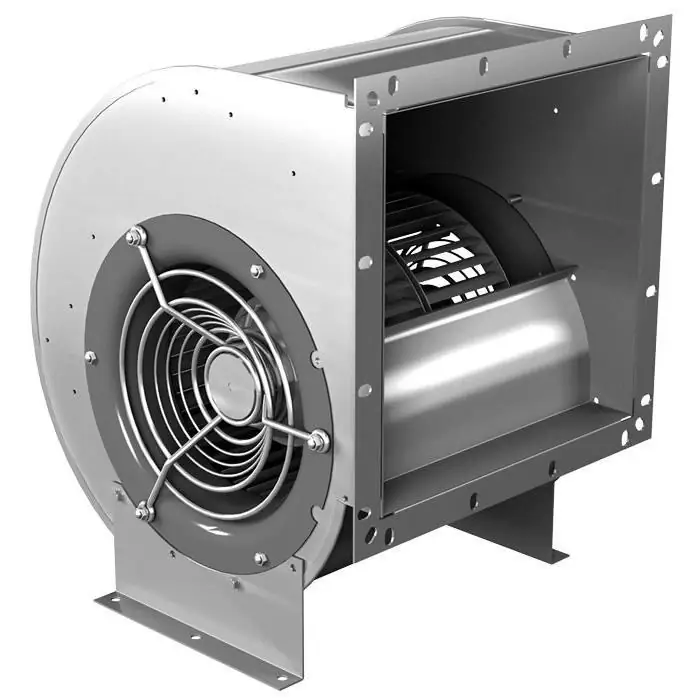

Industrial fans: specifications, types, purpose

Establishing an efficient and reliable air ventilation system at the enterprise is the first step towards creating comfortable conditions for employees. Ventilation of premises can be carried out in a natural and forced way. In the second case, industrial fans are required for operation, the technical characteristics of which will determine the efficiency of the entire ventilation system

Industrial pipes: types, characteristics, purpose

Industrial pipe is a tubular section or hollow cylinder, but not necessarily round. It is used more often for transporting substances, liquids, gases, suspensions, powders and small solids. Various types of pipes are used in industry, they differ not only in diameter and material, but also in the method of installation. Their classification is extensive, but to understand it, you should study the types of pipes used in various industries

Steel support: types, types, characteristics, purpose, installation rules, operation features and applications

Steel poles today are most often used as lighting poles. With their help, they equip the lighting of roads, streets, courtyards of residential buildings, etc. In addition, such structures are often used as supports for power lines

Lamp DRL 250 - characteristics, features, principle of operation and reviews

The article will study DRL 250 lamps, the characteristics of which are currently optimal for use in many areas of human life